Multi-paint composition system of low temperature rapidly cured powdery paints, coating method thereof, and coating

A powder coating and rapid curing technology, which is applied in powder coatings, coatings, polyester coatings, etc., can solve the problems of difficulty in ensuring the stability and reliability of ultra-low temperature curing, poor surface resistance of coating films, and differences in low-temperature curing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: a kind of multi-coat combination system of low-temperature fast-curing powder coatings, including the primer powder coating for base material primer and the top coating powder coating for base material top coating, wherein,

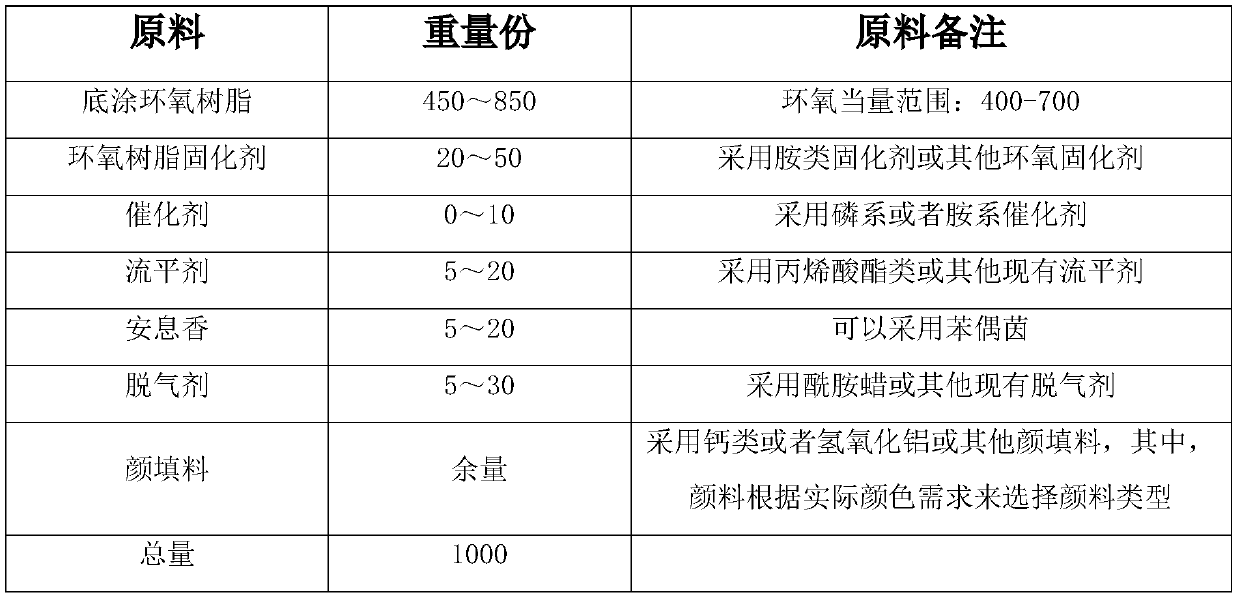

[0040] The formulation of the primer powder coating adopts the raw materials shown in the following table 3:

[0041] The formula of priming powder coating in table 3 embodiment 1

[0042] Raw material type parts by weight Specific raw material model epoxy resin 600 Adopt KD-211D of Guodu Chemical Epoxy curing agent 45 Using amine curing agent catalyst 5 Using Phosphorus Curing Agent leveling agent 10 Using ESTRON's RESIFLOW P-67A Benzoin 12 Using AXX-BENZOIN from Nanhai Chemical Degasser 20 CERAFLOUR 961 from BYK Pigments 308 Aluminum hydroxide Total 1000 /

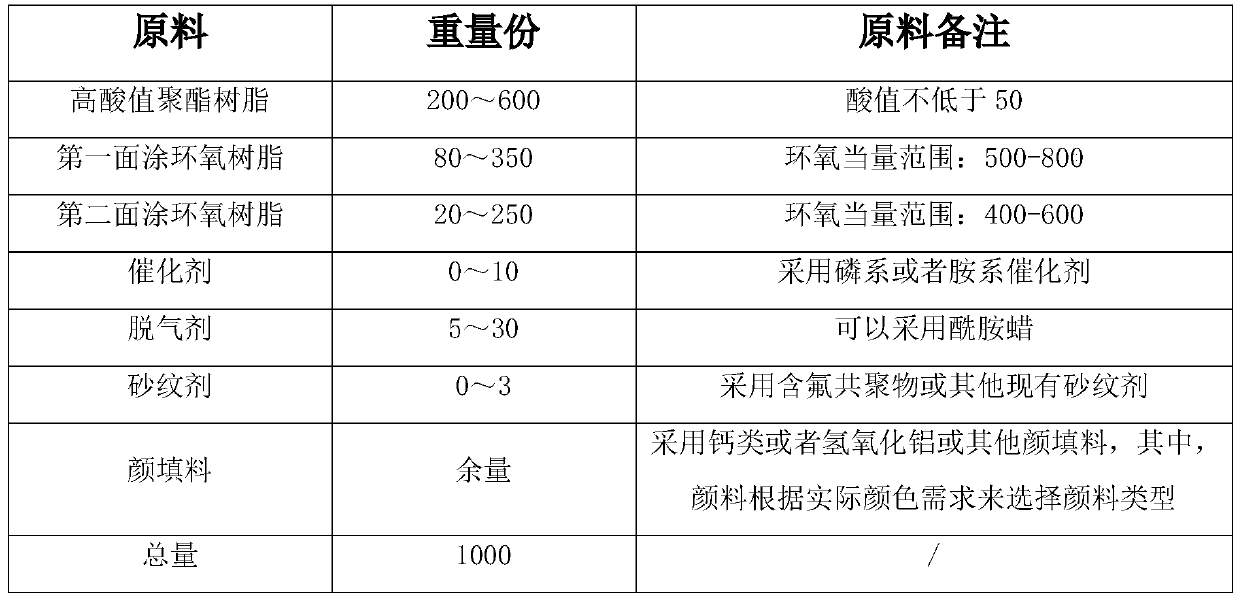

[0043] The formulation of surface coating powder coating adopts the raw materials shown in the f...

Embodiment 2

[0060] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the only difference being that in step S10) in this embodiment 2, the temperature of the infrared curing chamber is maintained at 130° C., and the curing time is selected as 1 minute.

Embodiment 3

[0061] Embodiment 3: The remaining technical solutions of this embodiment 3 are the same as those of embodiment 1, the only difference being that in step S10) of this embodiment 3, the temperature of the infrared curing chamber is maintained at 110° C., and the curing time is selected as 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com