Extinction curing agent for epoxy resin powder coating, preparation method of extinction curing agent and powder coating composition

A technology of epoxy resin powder and matting curing agent, applied in the field of powder coatings, can solve the problems of increased use cost, and achieve the effects of not easy to yellow, reduce use cost and good matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

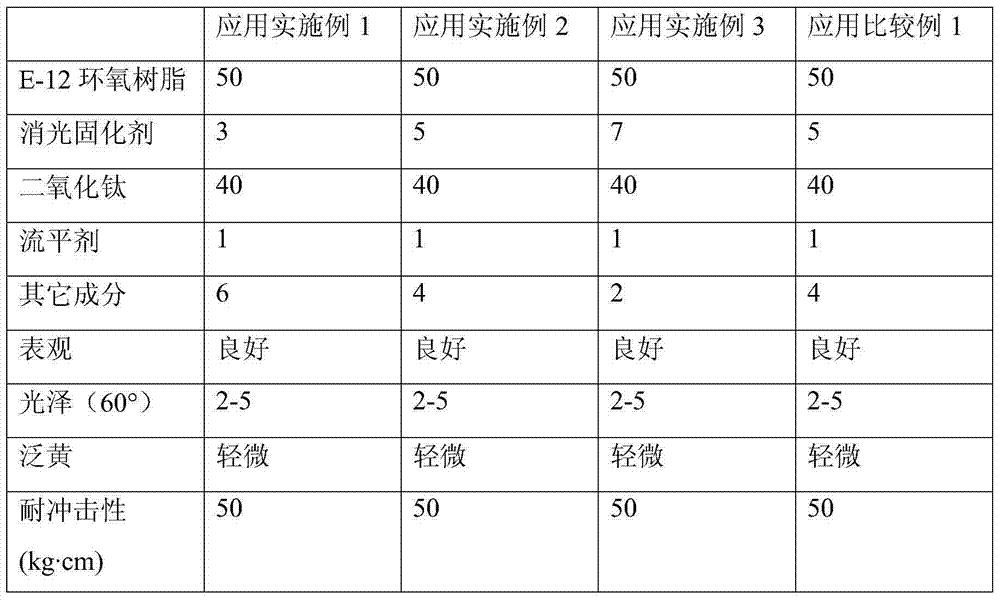

Examples

Embodiment 1

[0047] Prepare the matting curing agent of embodiment 1 according to the following method:

[0048] A. A copolymer of 60mol% fumaric acid and mesaconic acid (molar ratio 1:1, Mn=800-1200), 25mol% tartaric acid, 10mol% citric acid, 5mol% 1,2-diamino Cyclohexanetetraacetic acid is added into the reactor in turn, and then an appropriate amount of ethanol is added as a solvent, and mixed and stirred;

[0049] B. Add 5mol% ethylenediamine and 45mol% diethylenetriamine to the above polybasic acid. After mixing evenly, gradually heat up to the boiling point of ethanol at about 78°C for reflux reaction for 1h, then add 50mol% phthalate dropwise The ethanol solution of amine, the time of dropping is kept at 1h, and then the reflux reaction is carried out for 3h;

[0050] C. Finally, the ethanol solvent was removed by distillation, and the reaction mixture was lowered to room temperature to precipitate crystals, vacuum filtered and dried to obtain the product of Example 1.

Embodiment 2

[0052] Prepare the extinction curing agent of embodiment 2 according to the following method:

[0053] A. A copolymer of 80mol% fumaric acid and mesaconic acid (molar ratio 1:1, Mn=800-1200), 10mol% tartaric acid, 5mol% citric acid, 5mol% 1,2-diamino Cyclohexanetetraacetic acid is added into the reactor in turn, and then an appropriate amount of ethanol is added as a solvent, and mixed and stirred;

[0054] B. Add 10mol% ethylenediamine and 75mol% diethylenetriamine to the above-mentioned polybasic acid. After mixing evenly, gradually heat up to the boiling point of ethanol at about 78°C for reflux reaction for 2 hours, and then dropwise add 15mol% phthalate The ethanol solution of the amine, the dropping time is maintained at 1h, and then the reflux reaction is carried out for 4h;

[0055] C. Finally, the ethanol solvent was removed by distillation, and the reaction mixture was lowered to room temperature to precipitate crystals, vacuum filtered and dried to obtain the produ...

Embodiment 3

[0057] Prepare the matting curing agent of embodiment 3 according to the following methods:

[0058] A. A copolymer of 75mol% fumaric acid and mesaconic acid (molar ratio 1:1, Mn=800-1200), 15mol% tartaric acid, 7.5mol% citric acid, 2.5mol% 1,2- Add diaminocyclohexanetetraacetic acid into the reactor in turn, then add an appropriate amount of ethanol as a solvent, and mix and stir;

[0059]B. Add 30mol% ethylenediamine and 45mol% diethylenetriamine to the above-mentioned polybasic acid. After mixing evenly, gradually heat up to the boiling point of ethanol at about 78°C for reflux reaction for 1.5h, and then dropwise add 25mol% o-phthalic acid The ethanol solution of diamine, the time of dropping is maintained at 1h, and then reflux reaction is carried out for 5h;

[0060] C. Finally, the ethanol solvent was removed by distillation, and the reaction mixture was lowered to room temperature for crystallization, vacuum filtration and drying to obtain the product of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com