A kind of co-extruded biaxially stretched pet/pps composite film and preparation method thereof

A composite film and two-way stretching technology, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem that the glass transition temperature of PET and PPS is different, and the two materials cannot be heated at the same temperature. Stretching, stretching temperature mismatch and other problems, to achieve the effect of not easy to degrade, less precipitation, and improve bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of co-extruded biaxially stretched PET / PPS composite film, the steps are:

[0048] 1. Preparation of modified PET resin

[0049] Basic process: based on 1000 moles of dibasic acid, and 1000 moles of dibasic acid is the mixed sum of 990-910 moles of terephthalic acid and 10-90 moles of other dibasic acids;

[0050] Add 990-910 moles of terephthalic acid, 10-90 moles of other dibasic acids, 1000 moles of ethylene glycol and 0-200 moles of other glycols into the reactor, raise the temperature and control the initial pressure in the reactor to 0.2MPa, when the reactor The internal temperature rises to 230-250°C (Temperature A), collects the water distilled from the esterification, and calculates the esterification rate based on the water output. When the esterification rate reaches 97%, slowly release the pressure, and add 0.13-0.23mol of distillate Antimony is used as a catalyst, and 0.025-0.036mol of triphenyl phosphate is added as a stabilizer, stir...

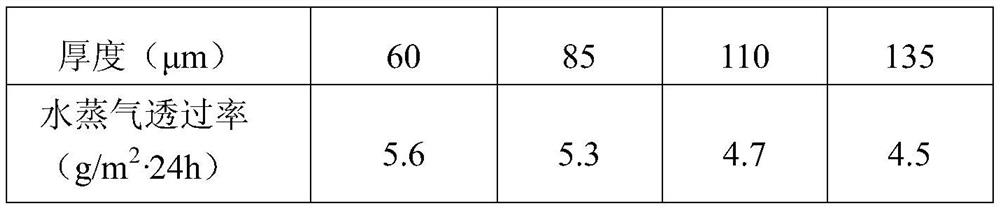

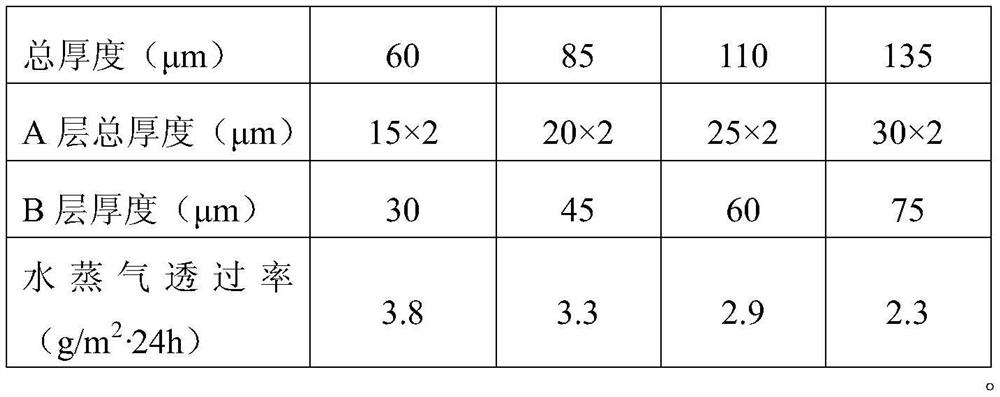

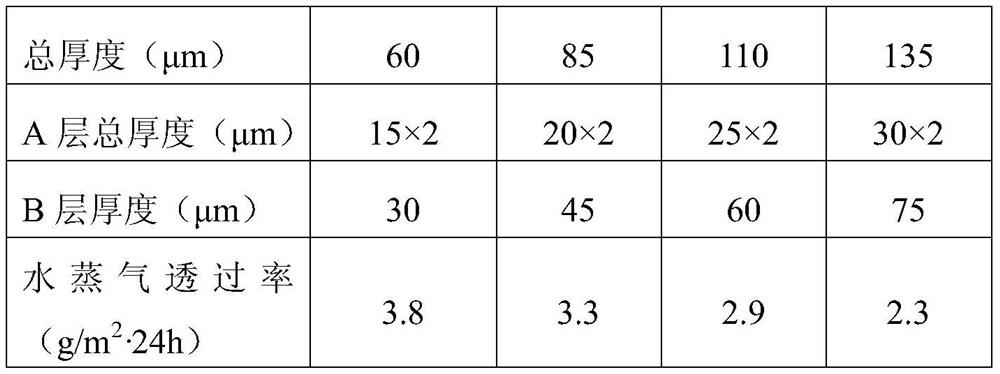

Embodiment 4

[0072] A co-extruded biaxially oriented PET / PPS composite film is characterized in that: the co-extruded biaxially oriented PET / PPS composite film is an ABA three-layer composite film with a total thickness of 60 μm, wherein: layer A is modified PPS, The B layer is modified PET, the thickness of the (single) A layer is 15 μm and the (front and back) two A layers are of equal thickness, and the thickness of the B layer is 30 μm.

Embodiment 5

[0074] A co-extruded biaxially oriented PET / PPS composite film is characterized in that: the co-extruded biaxially oriented PET / PPS composite film is an ABA three-layer composite film with a total thickness of 135 μm, wherein: layer A is modified PPS, The B layer is modified PET, the (single) A layer has a thickness of 30 μm and the (front and back) two A layers have the same thickness, and the B layer has a thickness of 75 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com