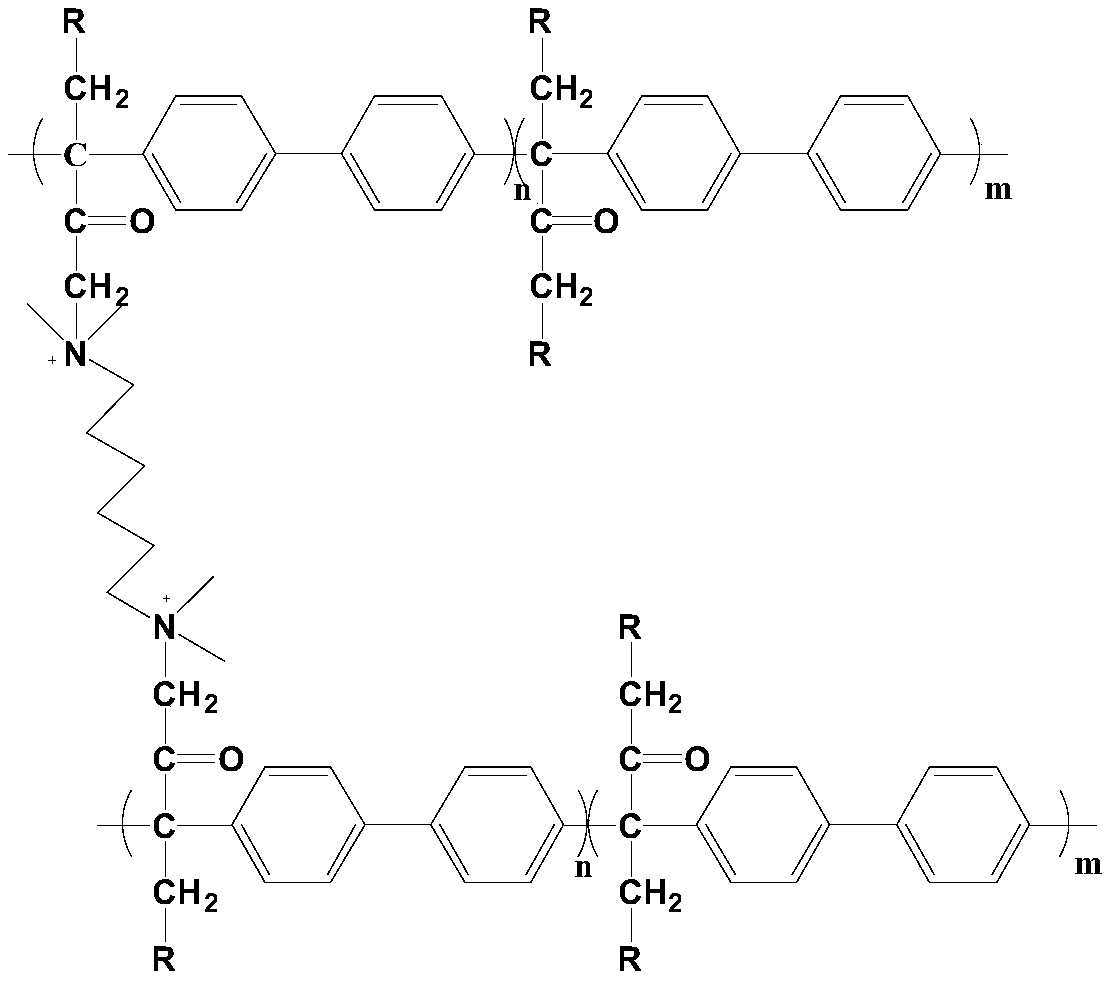

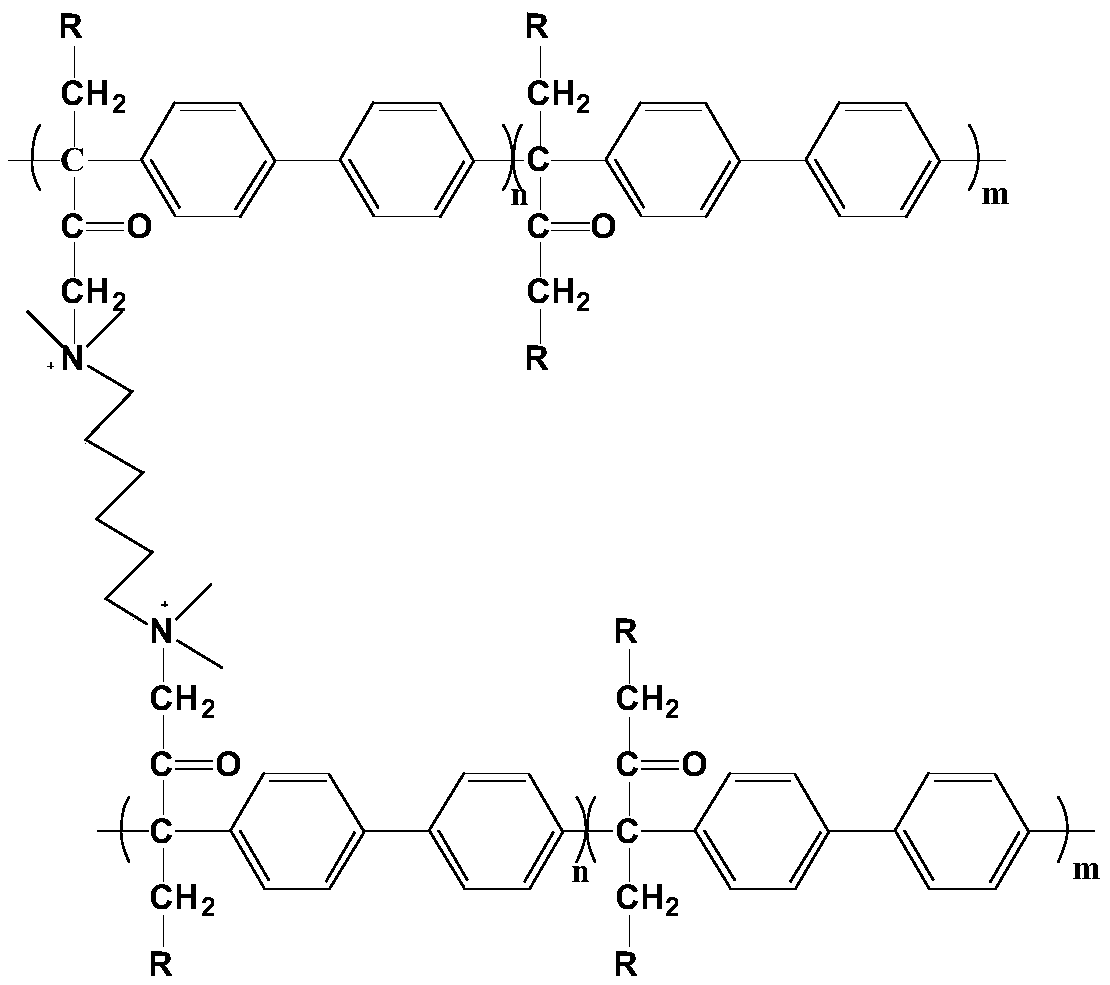

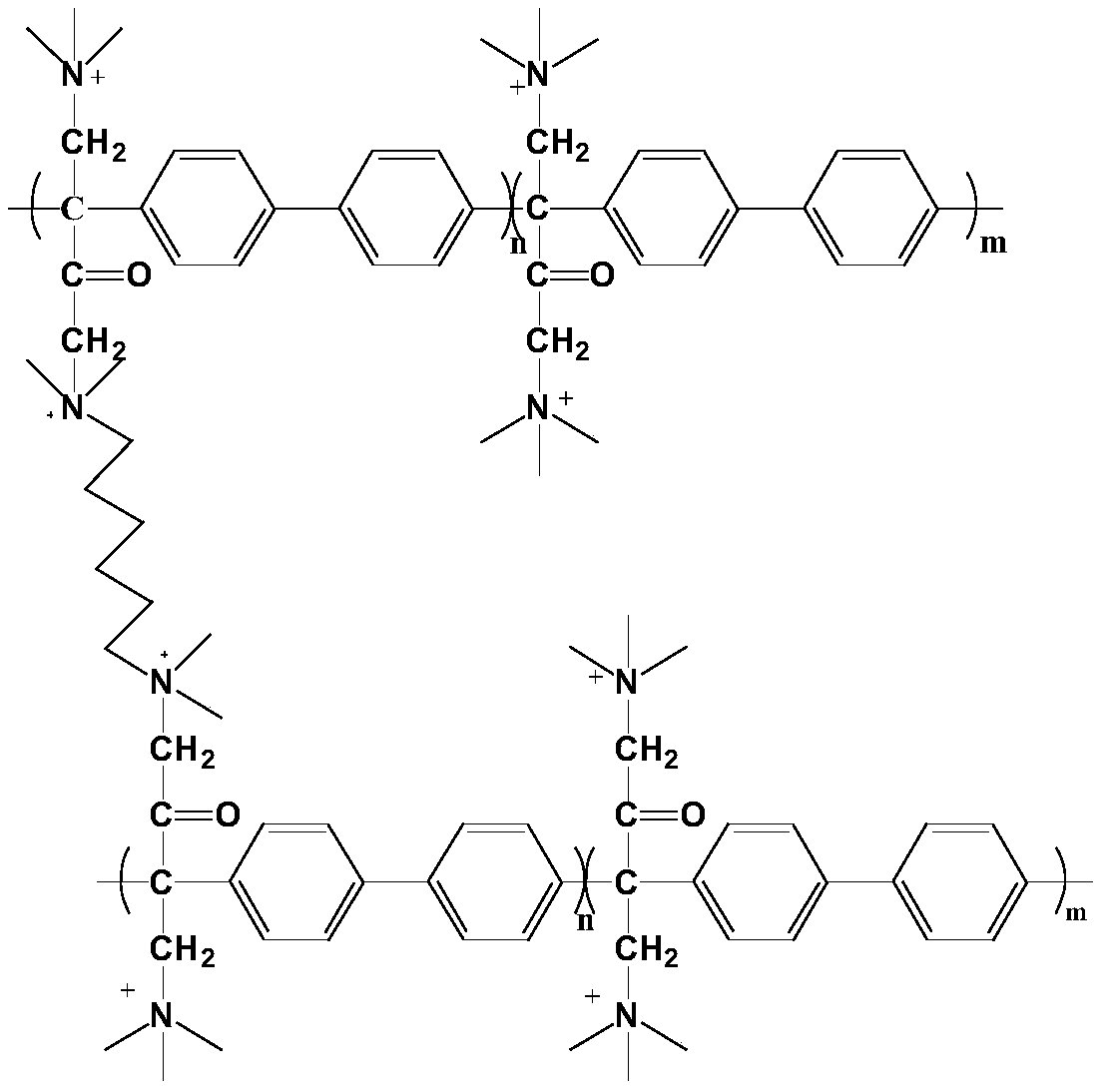

Multifunctional crosslinked polyarylidene butanedione anion exchange membrane and preparation method thereof

A poly(arylene butanedione), anion exchange membrane technology, applied in electrochemical generators, fuel cells, electrical components, etc. performance, good alkali resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Synthesis of dibromo-substituted polyarylene butanedione: Add 4.024g (16.5mmol) of 1,4-dibromo-2,3-butanedione and 2.313g (15mmol) of biphenyl into a 50mL single-necked flask, Add 22.5mL of dichloromethane and 5.3mL of trifluoromethanesulfonic acid, react at 0°C for 6h. After the reaction is completed, the product is slowly poured into methanol under stirring, and a filamentous polymer product is precipitated. The product is repeatedly washed and soaked with methanol, and then dried to obtain a polymer. Dissolve the polymer with N-methylpyrrolidone into a solution of a certain concentration. After the solution is completely dissolved, pour the solution into methanol to precipitate the polymer. After repeated washing several times, dry it in a vacuum oven for 6 hours at room temperature to obtain a polymer product.

[0031] Synthesis of combined polyarylene butanedione anion exchange membrane: Dissolve 0.16 g of dibromosubstituted polyarylene butanedione in 4.4 mL of N-m...

Embodiment 2

[0037] Synthesis of dibromo-substituted polyarylene butanedione: Add 4.024g (16.5mmol) of 1,4-dibromo-2,3-butanedione and 2.313g (15mmol) of biphenyl into a 50mL single-necked flask, Add 22.5mL of dichloromethane and 5.3mL of trifluoromethanesulfonic acid, react at 0°C for 6h. After the reaction is completed, the product is slowly poured into methanol under stirring, and a filamentous polymer product is precipitated. The product is repeatedly washed and soaked with methanol, and then dried to obtain a polymer. Dissolve the polymer with N-methylpyrrolidone into a solution of a certain concentration. After the solution is completely dissolved, pour the solution into methanol to precipitate the polymer. After repeated washing several times, dry it in a vacuum oven for 6 hours at room temperature to obtain a polymer product.

[0038] Synthesis of combined polyarylene butanedione anion exchange membrane: Dissolve 0.16 g of dibromosubstituted polyarylene butanedione in 4.4 mL of N-m...

Embodiment 3

[0044] Synthesis of dibromosubstituted polyarylene butanedione: same as Example 2

[0045]Synthesis of combined polyarylene butanedione anion exchange membrane: Dissolve 0.16 g of dibromosubstituted polyarylene butanedione in 4.4 mL of N-methylpyrrolidone in a 25 mL one-necked flask, add 4.4 μL of N,N, N',N'-tetramethyl-1,6-hexanediamine, stirred for 30 minutes, centrifuged the casting solution and cast it in a glass mold, dried at 30°C for 24 hours, and then heated to 60°C for 24 hours to obtain a polymer film .

[0046] Preparation of multifunctional cross-linked polyarylene butanedione anion exchange membrane: Soak the joint polyarylene butanedione anion exchange membrane in 10% N-methylpiperidine aqueous solution at 80°C for 48h, Then soak in deionized water for 24 hours, then soak in 1mol / L KOH solution at room temperature for 48 hours, then repeatedly wash with deionized water and soak for 48 hours until neutral, then the multi-functional cross-linked polyarylene Diace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com