Inorganic salt type carbon dioxide absorbent

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation of dispersed particles, air quality improvement, etc., can solve the problems of large operating loss, unfriendly environment, easy degradation, etc., and achieve reduced operating costs, environmental friendliness, and easy Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

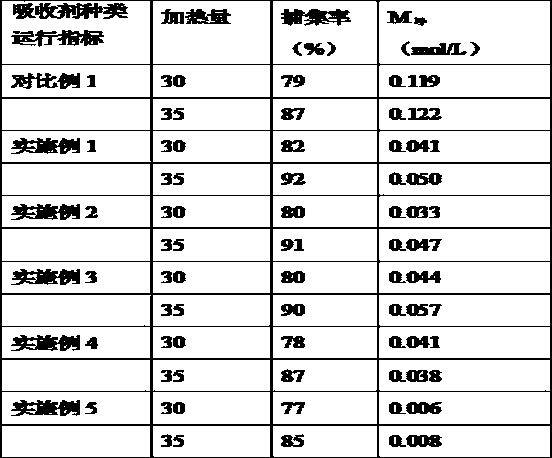

[0018] Raw gas intake volume is 3.5Nm 3 , the circulation volume is 12L / h, the regeneration heating capacity is 30% or 35%, the absorbent includes potassium sarcosinate 2.3mol / L, ammonia water 0.2mol / L, cobalt nitrate hexahydrate 2g / L, 1-butyl-3-methyl The imidazole tetrafluoroborate is 1.6 mol / L, and the rest is water. According to practical experience, the operating loss is mainly the amount of the part that is taken away by the absorbent during the discharge of the purified gas. Therefore, the alkalinity (mol / L) in the purified gas condensate is measured and recorded as M 净 , and the capture capacity is recorded as the capture rate under the same conditions.

[0019] The results are shown in Table 1 below.

Embodiment 2

[0024] Raw gas intake is 3.5 Nm 3 , the circulation rate is 12L / h, the regeneration heating capacity is 30% or 35%, the absorbent includes potassium glycinate 2.2mol / L, ammonia water 0.3mol / L, cobalt nitrate hexahydrate 2.5g / L, 1-butyl-3-methyl Imidazolium tetrafluoroborate is 1.6mol / L, and the rest is water. According to practical experience, the operating loss is mainly the amount of the part that is taken away by the absorbent during the discharge of the purified gas. Therefore, the alkalinity (mol / L) in the purified gas condensate is measured and recorded as M 净 , and the capture capacity is recorded as the capture rate under the same conditions. The results are shown in Table 1 below:

Embodiment 3

[0026] Raw gas intake is 3.5 Nm 3 , the circulation rate is 12L / h, the regeneration heating capacity is 30% or 35%, the absorbent includes potassium glycinate 1.8mol / L, potassium 2-methylalanine 0.5mol / L, ammonia water 0.2mol / L, cobalt nitrate hexahydrate 2g / L, 1-ethyl-3-methylimidazole acetate 2mol / L, the rest is water. According to practical experience, the operating loss is mainly the amount of the part that is taken away by the absorbent during the discharge of the purified gas. Therefore, the alkalinity (mol / L) in the purified gas condensate is measured and recorded as M 净 , and the capture capacity is recorded as the capture rate under the same conditions. The results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com