A kind of cotton fabric non-aqueous dyeing process and reactive dye solution encapsulated by reverse micelles

A reactive dye and process technology, applied in the textile field, can solve the problems of poor dyeing effect and unstable "pool", and achieve the effect of easy and safe operation, good dyeing effect and good dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

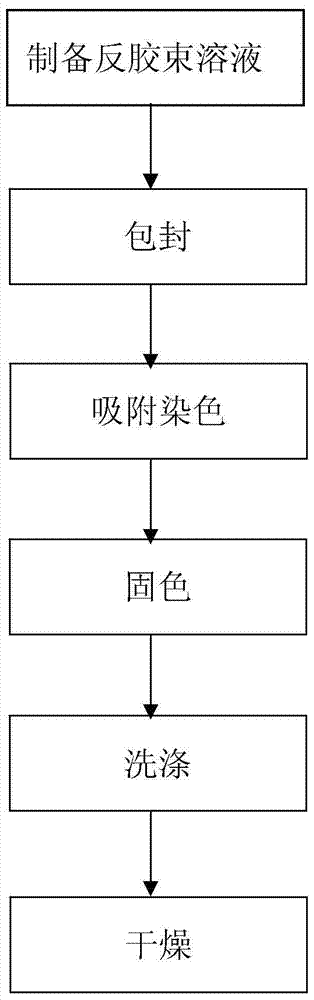

Method used

Image

Examples

Embodiment 1

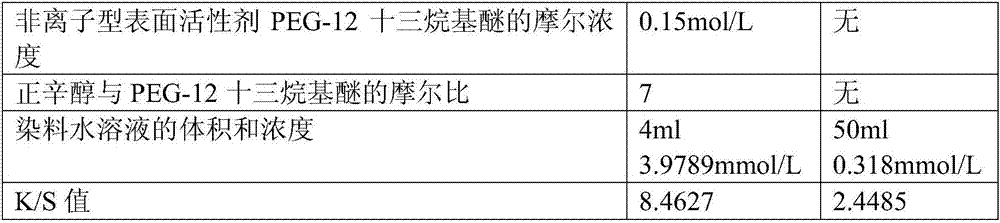

[0047] In this embodiment, the nonionic surfactant is polyethylene glycol-12-tridecyl ether, that is, R in the molecular formula 1 For H, R 2 Linear C 13 Alkyl, n is 12. At room temperature, 0.105 mol of n-octanol and 0.015 mol of non-ionic surfactant are pre-mixed in a beaker by stirring. The ratio is 7:1. After mixing, they are dissolved in 100ml of n-octane to form a total of 100ml. The reverse micelle solution is divided into 50ml of the first reverse micelle solution and 50ml of the second reverse micelle solution; a certain amount of Levafix Red CA reactive dye is dissolved in a very small amount of 4ml of water to form a concentration of 3.9789mmol / L Slowly inject the reactive dye solution into the first reverse micelle solution. After injecting, stir vigorously at 600 rpm for 10 minutes, and then the solution clarifies to obtain the reactive dye solution encapsulated by reverse micelles; sample 1g of cotton fabric Immerse in the reactive dye solution encapsulated by rev...

Embodiment 2

[0055] In this embodiment, in the molecular formula of the nonionic surfactant, R 1 Is C 2 Type alkyl, R 2 Linear C 12 Alkyl, n is 10. At room temperature, 0.105 mol of n-octanol and 0.0175 mol of non-ionic surfactant are pre-mixed in a beaker by stirring. The ratio is 6:1. After mixing, they are dissolved in 100 ml of n-octane to form 100 ml of total The reverse micelle solution is divided into 50ml of the first reverse micelle solution and 50ml of the second reverse micelle solution; a certain amount of Levafix Red CA reactive dye is dissolved in a small amount of 2ml of water to form a reactive dye with a concentration of 3mmol / L Solution, slowly inject the reactive dye solution into the first reverse micelle solution. After the injection, stir vigorously at 800 rpm for 15 minutes and then the solution clarifies to obtain the reactive dye solution encapsulated by reverse micelles; bath a sample of 1.25g cotton fabric The ratio of 1:40 is immersed in the reactive dye solution...

Embodiment 3

[0057] In this embodiment, in the molecular formula of the nonionic surfactant, R 1 Is C 3 Type alkyl, R 2 C for the branch 10 Alkyl, n is 8. At room temperature, premix 0.0525 mol of n-octanol and 0.0065625 mol of non-ionic surfactant in a beaker by stirring. The ratio is 8:1. After mixing, dissolve in 50ml of n-octane to form 50ml of first A reverse micelle solution; prepare 50ml of the second reverse micelle solution in the same way as above; dissolve a certain amount of Levafix Red CA reactive dye in a very small amount of 4ml of water to form a reactive dye solution with a concentration of 5mmol / L. The dye solution was slowly injected into the first reverse micelle solution. After injection, the solution was clarified after being vigorously stirred at 1000 rpm for 15 minutes to obtain the reactive dye solution encapsulated in reverse micelles; the 2g cotton fabric sample was set to a bath ratio of 1:25 The ratio is immersed in the reactive dye solution encapsulated in reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com