Preparation method of bi-component fibers

A bicomponent fiber and fiber technology, which is applied in the field of fiber materials, can solve the problems of affecting the smoothness of the fabric surface, not being able to be dyed at low temperature, and the fiber material being easily damaged, achieving a good cotton imitation effect, narrowing the gap in thermal performance, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

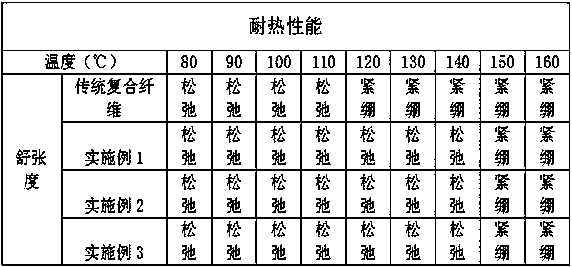

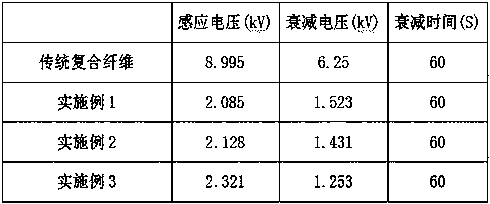

Embodiment 1

[0029] Preparation of PBT / PET Fiber

[0030] The mass ratio of PBT and PET is 1:1. PBT slices are dried, mixed with PMMA powder at a mass ratio of 10:1, extruded by screw at low temperature, melted and extruded at high temperature, metered and then entered into side-by-side composite components for side-by-side compound distribution. Side-by-side compounding with PET at the spinneret; PET slices are dried, mixed with PMMA powder at a mass ratio of 10:1, extruded through high-temperature melting and low-temperature extrusion of the screw, metered, and then entered into a side-by-side compound component for parallel compound distribution, and in the compound spinneret Side-by-side compounding at the plate and PBT; the side-by-side composite fiber coming out of the spinneret undergoes ring blowing, oiling, winding traction, feeding, and silk filling to obtain the winding filament of the side-by-side composite fiber; winding of the side-by-side composite fiber The silk is balanced...

Embodiment 2

[0039] Preparation of PBT / PET fibers

[0040] The mass ratio of PBT and PET is 1:1, the PBT chips are dried, mixed with PMMA powder according to the mass ratio of 10:2, extruded by screw at low temperature, melted at high temperature, metered, and then entered into the side-by-side composite component for side-by-side compound distribution, and in the compound Side-by-side compounding with PET at the spinneret; PET slices are dried, mixed with PMMA powder at a mass ratio of 10:2, extruded through high-temperature melting and low-temperature extrusion of the screw, metered, and then entered into a side-by-side compound component for parallel compound distribution, and in the compound spinneret Side-by-side compounding at the plate and PBT; the side-by-side composite fiber coming out of the spinneret undergoes ring blowing, oiling, winding traction, feeding, and silk filling to obtain the winding filament of the side-by-side composite fiber; winding of the side-by-side composite ...

Embodiment 3

[0049] Preparation of PBT / PET fibers

[0050] The mass ratio of PBT and PET is 1:1, the PBT chips are dried, mixed with PMMA powder according to the mass ratio of 10:3, extruded through the screw at low temperature and high temperature, measured, and then entered into the side-by-side composite component for parallel compound distribution, and in the compound Side-by-side compounding with PET at the spinneret; PET slices are dried, mixed with PMMA powder at a mass ratio of 10:3, extruded through high-temperature melting and low-temperature extrusion of the screw, metered, and then entered into a side-by-side compound component for parallel compound distribution, and in the compound spinneret Side-by-side compounding at the plate and PBT; the side-by-side composite fiber coming out of the spinneret undergoes ring blowing, oiling, winding traction, feeding, and silk filling to obtain the winding filament of the side-by-side composite fiber; winding of the side-by-side composite f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com