Method for preparing uramine-type macromolecule anti-bacterial agent

A polymer type, antibacterial agent technology, applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problems of poor thermal stability, easy migration of antibacterial ions or groups, uneven dispersion, etc., to achieve difficult migration , remarkable antibacterial effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

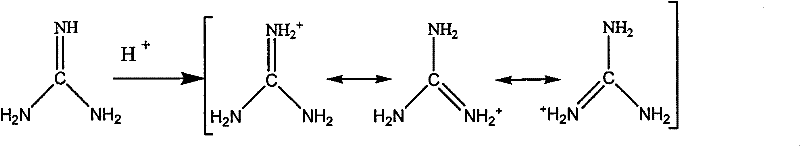

Problems solved by technology

Method used

Image

Examples

Embodiment 1

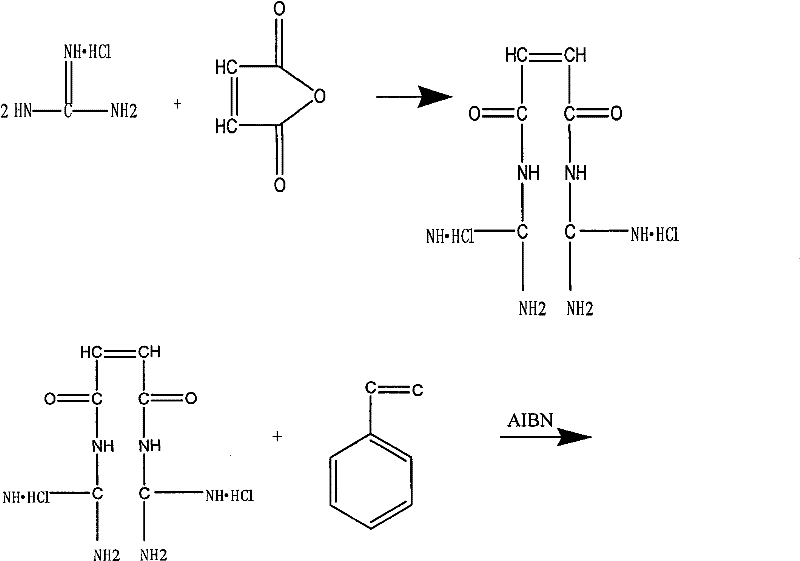

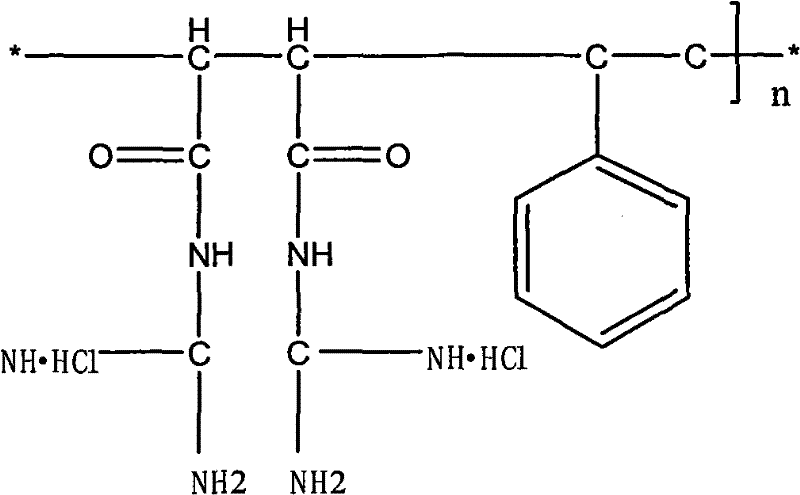

[0029] The preparation method of guanidine polymer type antibacterial agent comprises the following steps:

[0030] A, 15g maleic anhydride is added in 40g dehydrated alcohol to be made into the maleic anhydride solution that massfraction is 27.3%, and 20g guanidine hydrochloride is added in 40g dehydrated alcohol to be made into massfraction and be 33.3% guanidine hydrochloride solution, described The two solutions were put into a three-necked flask, stirred, and a spherical condenser was added at the same time, nitrogen gas was introduced for 30 minutes, and reacted in a constant temperature water bath at 60°C for 7 hours to obtain a light yellow functionalized guanidine salt.

[0031] B, take by weighing 45g styrene and be dissolved in 75g dehydrated alcohol and be made into the styrene solution that mass fraction is 37.5%; Take by weighing 30g functionalized guanidine salt and be dissolved in 75g dehydrated alcohol and be made into the functionalized that massfraction is 28...

Embodiment 2

[0036] A, 15g maleic anhydride is added in 40g acetone and is made into the maleic anhydride solution that mass fraction is 27.3%, and 30g polyhexamethylguanidine hydrochloride is added in 40g acetone and is made into mass fraction and is 42.9% polyhexamethylguanidine For the hydrochloride solution, add the two solutions into a three-necked flask, stir, add a spherical condenser at the same time, pass nitrogen gas for 30 minutes, and react in a constant temperature water bath at 75°C for 6 hours to obtain a light yellow functionalized guanidine salt;

[0037] B, take by weighing 45g styrene and be dissolved in 75g toluene and be made into the styrene solution that massfraction is 37.5%, take by weighing 30g functionalized guanidine salt and be dissolved in 75g toluene and be made into the functionalized guanidine salt solution that massfraction is 28.6%;

[0038] Copolymerize the prepared functionalized guanidine salt solution with styrene solution, add 2.5g of dicumyl peroxide...

Embodiment 3

[0040] A, 15g maleic anhydride is added in 40g dehydrated alcohol to be made into the maleic anhydride solution that massfraction is 27.3%, and 20g guanidine hydrochloride is added in 40g dehydrated alcohol and is made into massfraction and is 33.3% guanidine hydrochloride solution, two kinds The solution was put into a three-necked flask, stirred, and a spherical condenser was added at the same time, and nitrogen gas was introduced for 30 minutes, and reacted in a constant temperature water bath at 85°C for 5 hours to obtain a light yellow functionalized guanidine salt.

[0041]B, take by weighing 45g styrene and be dissolved in 75g toluene and be made into the styrene solution that massfraction is 37.5%, take by weighing 30g functionalized guanidine salt and be dissolved in 75g toluene and be made into the functionalized guanidine salt solution that massfraction is 28.6%;

[0042] Mix the prepared functionalized guanidine salt solution with styrene solution for copolymerizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com