Packaged photovoltaic cell component and preparation method thereof

A photovoltaic cell and module technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of low light conversion efficiency of solar cells, waste of sunlight, etc., to improve the photoelectric conversion efficiency, expand the incident wavelength range, and narrow the wavelength range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

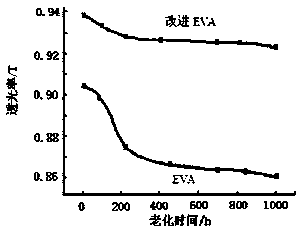

[0018] Encapsulation of photovoltaic cell components, including cover layer, graphene transparent conductive film layer, adhesive upper layer, photovoltaic cells, adhesive lower layer and substrate layer from top to bottom; the adhesive upper layer is modified ethylene-vinyl acetate copolymer Thin film layer, the preparation method of the improved ethylene-vinyl acetate copolymer film is as follows: in parts by mass, 30 parts of aluminum oxide and 1 part of coupling agent are fully mixed, dried at 80 ° C, ground and dispersed, and added to the Mix uniformly 1 part of curing agent and 100 parts of EVA pellets; then add 4 parts of ginseng ethyl ether and mix evenly; pour the mixture into the extruder for blending and extrusion, and the temperature is controlled at 100°C , after the extrudate is cast, cooled, drawn, and coiled, it can be obtained.

[0019] Both the covering layer and the base layer are made of transparent tempered glass; the lower layer of the adhesive is an ethy...

Embodiment 2

[0022] Encapsulation of photovoltaic cell components, including cover layer, graphene transparent conductive film layer, adhesive upper layer, photovoltaic cells, adhesive lower layer and substrate layer from top to bottom; the adhesive upper layer is ethylene-vinyl acetate copolymer Film layer, the preparation method of the improved ethylene-vinyl acetate copolymer film is: in parts by mass, fully mix 40 parts of aluminum oxide and 2 parts of coupling agent, dry at 80 ° C, grind and disperse, add to the mixed In a uniform mixture of 2 parts of curing agent and 100 parts of EVA pellets, mix evenly; pour the mixture into the extruder for blending and extrusion, the temperature is controlled at 100 ° C, and the extruded product is cast, cooled, Traction, coiling process, that is.

[0023] Both the covering layer and the base layer are made of transparent toughened glass; the lower layer of the adhesive is an ethylene-vinyl acetate copolymer film layer. The coupling agent is ZQ-...

Embodiment 3

[0026]Encapsulation of photovoltaic cell components, including cover layer, graphene transparent conductive film layer, adhesive upper layer, photovoltaic cells, adhesive lower layer and substrate layer from top to bottom; the adhesive upper layer is modified ethylene-vinyl acetate copolymer The preparation method of the improved ethylene-vinyl acetate copolymer film is as follows: in parts by mass, 70 parts of aluminum oxide and 2 parts of coupling agent are fully mixed, dried at 80 ° C, ground and dispersed, and added to the Mix evenly into the mixture of 2 parts of curing agent and 100 parts of EVA pellets; add 8 parts of ginseng ethyl ether and mix evenly; pour the mixture into the extruder for blending and extrusion, and the temperature is controlled at 100°C , after the extrudate is cast, cooled, drawn, and coiled, it can be obtained.

[0027] Both the covering layer and the base layer are made of transparent toughened glass; the lower layer of the adhesive is an ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com