Composite material taking carbon fiber/polyimide fiber hybrid fabric as enhancing body and preparation method thereof

A technology of polyimide fibers and composite materials, which is applied in the field of high-strength, high-temperature-resistant composite materials, and high toughness, and can solve problems such as poor toughness and impact resistance, low water absorption, low density, and dielectric insulation properties , to achieve the effect of improving toughness and impact resistance, improving toughness and impact resistance, and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

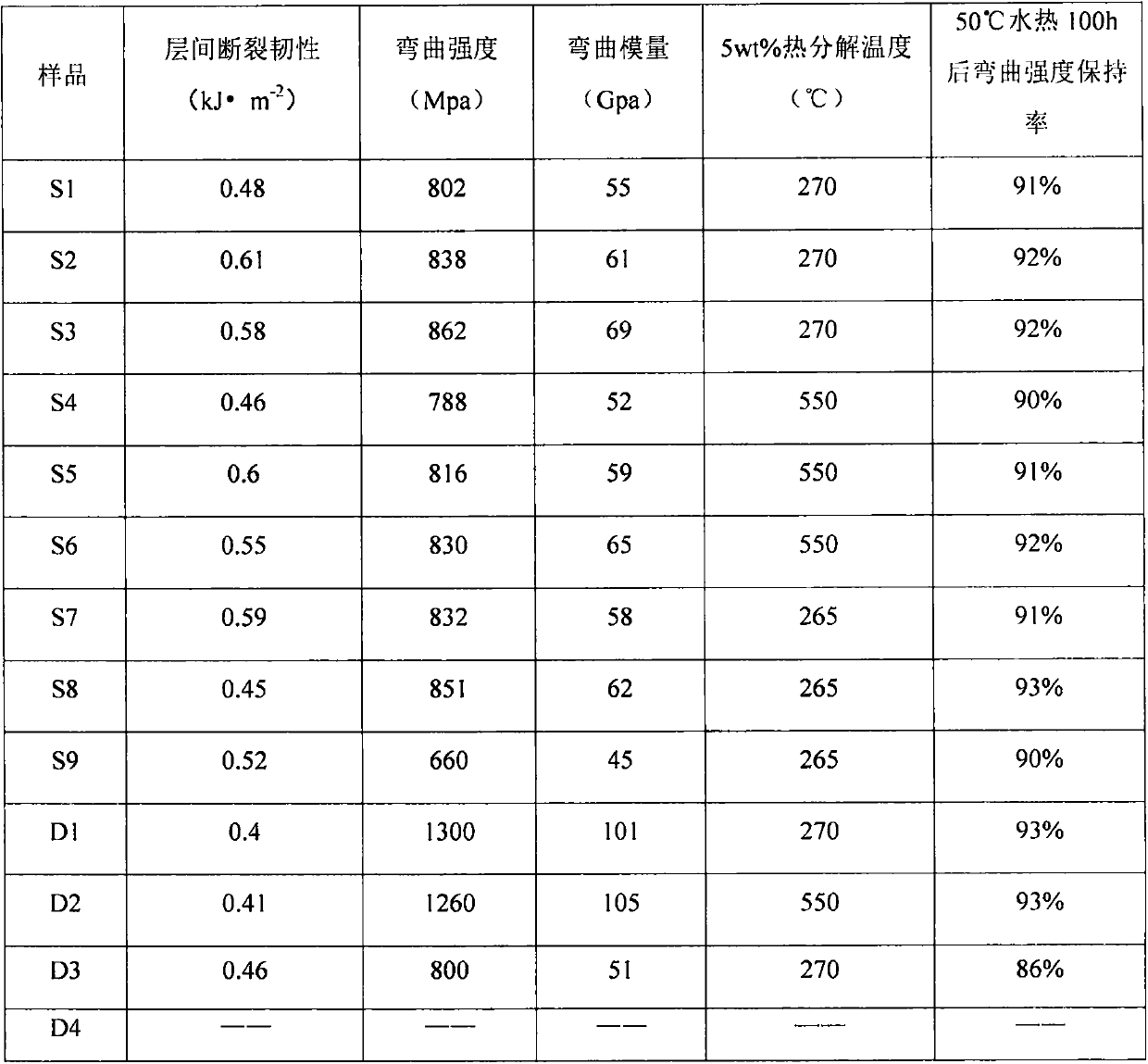

Examples

preparation example 1

[0039] The preparation method of thermosetting polyimide resin solution: 4-phenylethynyl phthalic anhydride (PEPA) and a-type biphenyltetracarboxylic dianhydride (a-BPDA) and a small amount of 2,2-bis[4-(3,4 -dicarboxyphenoxy) phenyl] hexafluoropropane dianhydride (BFDA) and ethanol were refluxed at 70°C to obtain the three esterified solutions A, B and C respectively, and p-phenylenediamine ( p-PDA) and 2,2'-bis[4-(4-aminophenoxy)phenyl]propane (BAPP) and 3,4-diaminodiphenyl ether (3,4-ODA) were dissolved in ethanol solution Solution D was obtained in , and solutions A, B and C were mixed with solution D under the condition of nitrogen protection, and the stirring reaction was continued for 2 hours to obtain a polyimide resin solution.

preparation example 2

[0041] The preparation method of thermoplastic polyimide resin: add bisphenol A type diether dianhydride (BPDEDA) and hexafluorotetracarboxylic dianhydride (6FDA) and 3,4-ODA and a small amount of p-PDA into a high boiling point solvent (N- Methylpyrrolidone NMP), polymerize at 190°C for 12h, then add catalyst isoquinoline (the mole is 5% of the mole of dianhydride), continue to polymerize at 190°C for 24h, then cool to At room temperature, the solution was poured into deionized water to precipitate, filtered and dried to obtain thermoplastic polyimide powder.

Embodiment 1

[0043] (1) Take the high-performance polyimide fiber (strength 2.5GPa, modulus 80GPa, elongation 3.5%) of 3K tow as the weft direction, take the T300 carbon fiber of 3K tow as the radial direction, and take plain weave The process obtains a fiber cloth mixed with the two, and the surface density of the fiber cloth is 180g / m 2 ;

[0044] (2) The fiber cloth obtained in step (1) is fully infiltrated with a hot roller (80°C) and an epoxy resin film to obtain a fiber cloth prepreg, and the glue amount is 120g / m 2 ;

[0045] (3) Lay up the prepreg obtained in step (2) (20 layers), and then put it into the mold. After preforming with a vacuum bag, pre-cure at 100°C for 3 hours under a pressure of 6MPa, and then cure at 180°C for 3 hours. Forming to obtain composite material S1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com