Adhesive composition with single-component epoxy structure

A structural adhesive, one-component technology, used in non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problems of weak strength, complex process, high manufacturing cost, and achieve moisture and heat aging resistance. Excellent, high shear strength, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

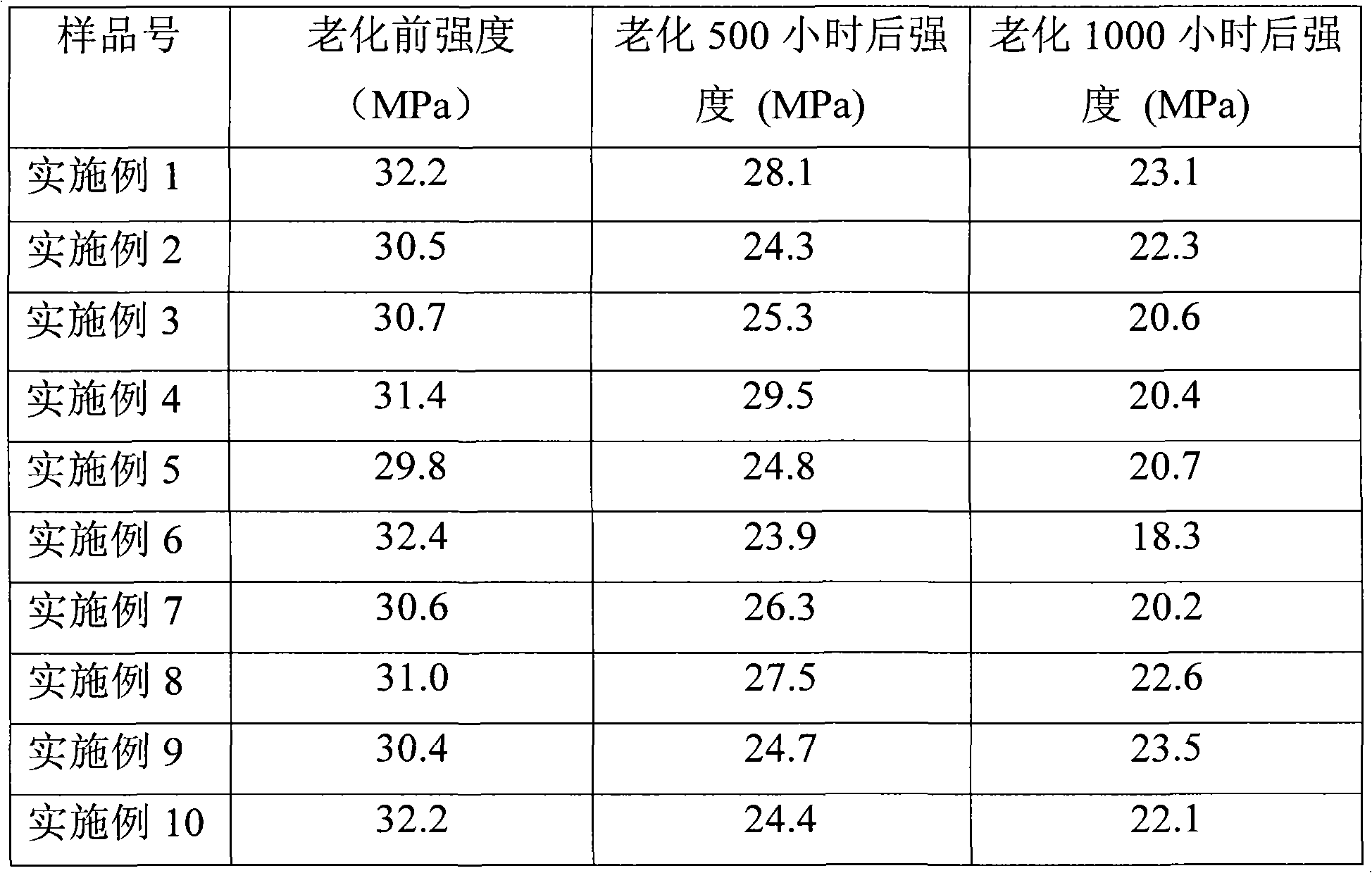

[0109] Embodiment 1 prepares single-component aging-resistant epoxy resin adhesive composition

[0110] First, prepare polyetheramine-modified bisphenol A epoxy resin prepolymer: add 100g EPON828 epoxy resin to 60g polyetheramine (D2000, Huntsman company) at 25°C, then add 3g phenyltrimethoxysilane Mix the coupling agents, then heat the mixture to 80°C at a heating rate of 2°C / min, react for 2 hours, then continue to heat at a heating rate of 2°C / min to 120°C, react for 1 hour, cool to room temperature, and discharge.

[0111] Stir and mix 100g bisphenol A type Epon828 epoxy resin, 300g MX153 core-shell structure modified resin, 107g polyether amine modified epoxy prepolymer, 120g phosphating modified bisphenol A epoxy resin EP49-10N at 50°C , the stirring rate is 800 rev / min, and the stirring and mixing time is 10 minutes, then add 24g NC513 monofunctional epoxy diluent, 150g wollastonite filler, 40g fumed silica, and 8g heat and humidity resistant aging agent in the above mi...

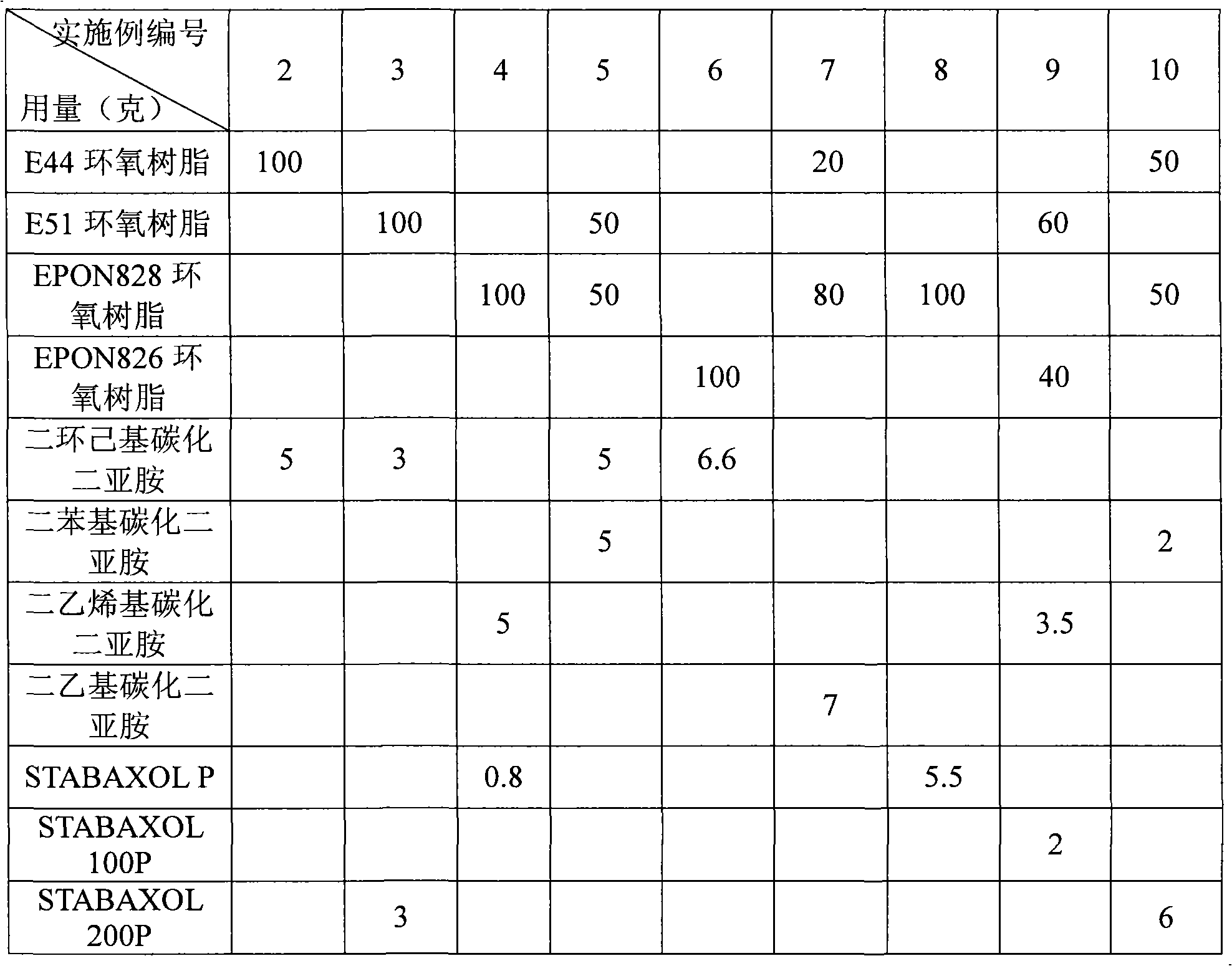

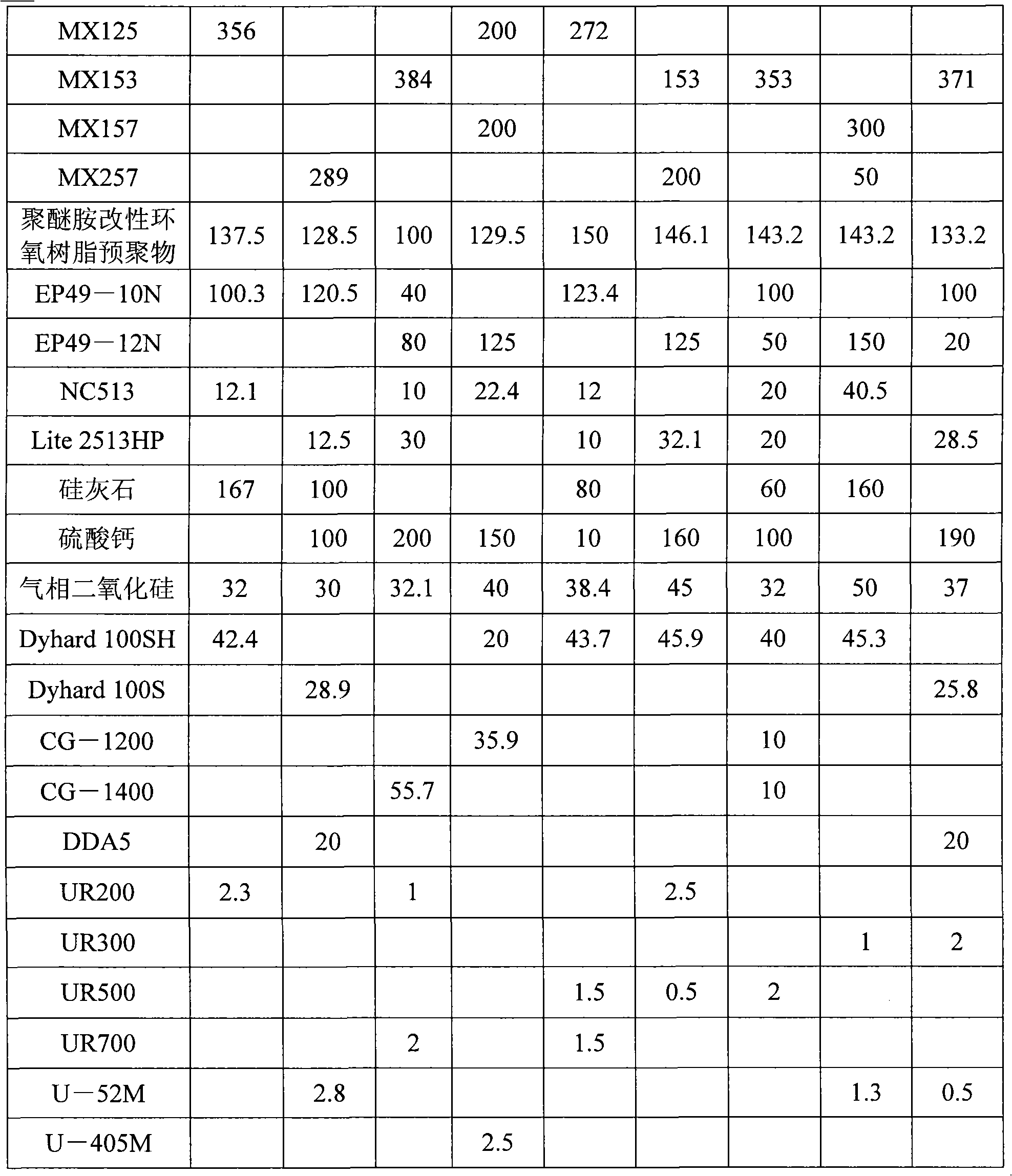

Embodiment 2~10

[0113] According to the composition and dosage ratio listed in Table 1, liquid bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, polyetheramine modified epoxy prepolymer, phosphating modified Bisphenol A epoxy resin is stirred and mixed, the stirring speed is 1000 rpm, and the stirring and mixing time is 10 minutes. Mix evenly, the stirring rate is 1000 rpm, and the stirring and mixing time is 15 minutes. Then cool the mixture to 25°C, add dicyandiamide curing agent and urea curing accelerator, stir and mix evenly, the stirring speed is 1000 rpm, and the stirring and mixing time is 10 minutes.

[0114] The preparation steps of the polyetheramine modified epoxy resin prepolymer used in Examples 2 and 3 are as follows: 100g of bisphenol A epoxy resin Epon828, 40g of polyetheramine D230, 2g of phenyltrimethoxy The silane coupling agent is mixed, heated to 90°C, reacted for 2 hours, then continued to heat up to 130°C, reacted for 1 hour, and obtained after cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com