Poly(lactic acid)/poly(methyl methacrylate) alloy material and preparation method thereof

A technology of polymethyl methacrylate and alloy materials, which is applied in the field of polylactic acid/polymethyl methacrylate alloy materials and their preparation, can solve the problems of modified polylactic acid losing transparency and being unable to make transparent products, etc. Achieve the effects of simple process, broadened application range and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

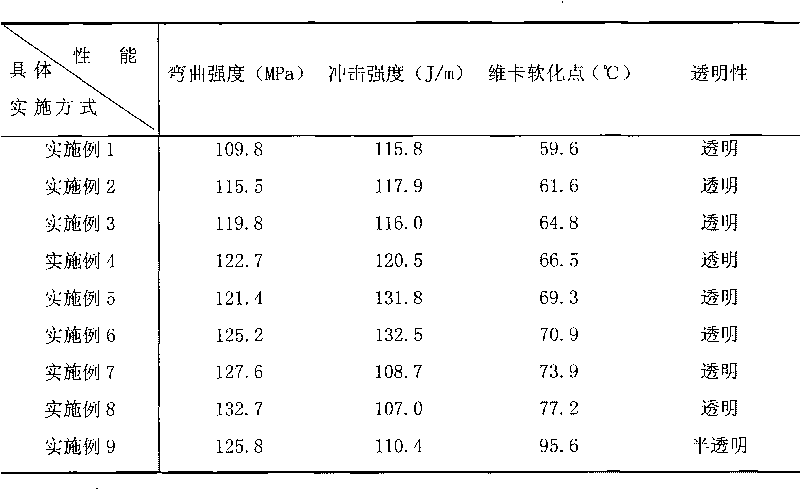

[0023] Example 1: After vacuum-drying 99 parts of semi-crystalline poly-L-lactic acid, add 0.5 part of heat stabilizer maleic anhydride and 0.5 part of lubricant aluminum stearate, put them in a high mixer and mix at room temperature, then Extrude and granulate in the extruder, the extrusion temperature is 180-200°C, and finally use the injection machine to make the pellets into impact and bending test specimens, and the injection temperature is 180-200°C. Its mechanical properties and heat resistance are listed in Table 1.

Embodiment 2

[0024] Example 2: After vacuum-drying 90 parts of semi-crystalline poly-L-lactic acid and 9 parts of polymethyl methacrylate, add 0.5 part of heat stabilizer maleic anhydride and 0.5 part of lubricant aluminum stearate, put Mix at room temperature in a high-speed mixer, then extrude and granulate in an extruder at a temperature of 180-200°C, and finally use an injection machine to make the pellets into impact and bending test specimens at an injection temperature of 180-200°C. Its mechanical properties and heat resistance are listed in Table 1.

Embodiment 3

[0025] Example 3: After vacuum-drying 82 parts of semi-crystalline poly-L-lactic acid and 17 parts of polymethyl methacrylate, add 0.5 part of heat stabilizer maleic anhydride and 0.5 part of lubricant aluminum stearate, put Mix at room temperature in a high-speed mixer, then extrude and granulate in an extruder at a temperature of 180-200°C, and finally use an injection machine to make the pellets into impact and bending test specimens at an injection temperature of 180-200°C. Its mechanical properties and heat resistance are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com