Heat-resistant wire and cable material used in electric power line and preparation method thereof

A technology for wire and cable materials and power lines, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor flame retardancy, poor heat resistance, and low strength, and achieve good wear resistance and heat resistance. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

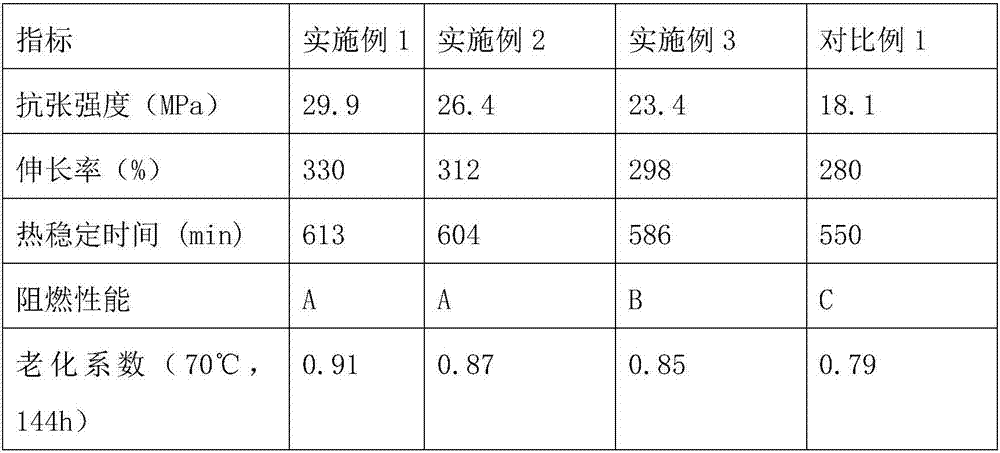

Examples

Embodiment 1

[0039] A heat-resistant wire and cable material used in power lines, comprising the following raw materials in parts by weight: 55 parts of polyvinyl chloride, 30 parts of neoprene CR121, 0.9 parts of dimethyl silicone oil, 6 parts of polypropylene fiber, chlorinated polyvinyl chloride 23 parts of ethylene, 16 parts of nano-silicon carbide, 6 parts of heavy calcium carbonate, 7 parts of nano-active calcium carbonate, 26 parts of trioctyl trimellitate, 5 parts of calcium-zinc stabilizer resistant to Congo red and non-discoloration, heat-resistant 4 parts of color-changing calcium zinc stabilizer, 4 parts of kaolin, 0.5 part of PE wax, 0.4 part of stearic acid, 0.6 part of flame retardant, 0.2 part of antioxidant, 0.3 part of coupling agent and 0.5 part of plasticizer;

[0040] Congo red non-discoloration calcium-zinc stabilizer is a calcium-zinc stabilizer that can withstand heat at 200°C, and the Congo red test paper will not turn blue after 300 minutes; Zinc stabilizer.

[0...

Embodiment 2

[0057] A heat-resistant wire and cable material used in power lines, comprising the following raw materials in parts by weight: 50 parts of polyvinyl chloride, 20 parts of neoprene rubber CR121, 0.6 parts of dimethyl silicone oil, 4 parts of polypropylene fiber, chlorinated polyvinyl chloride 15 parts of ethylene, 12 parts of nano-silicon carbide, 5 parts of heavy calcium carbonate, 5 parts of nano-active calcium carbonate, 24 parts of trioctyl trimellitate, 4 parts of Congo red-resistant calcium-zinc stabilizer, heat-resistant 3 parts of color-changing calcium zinc stabilizer, 3 parts of kaolin, 0.3 part of PE wax, 0.2 part of stearic acid, 0.4 part of flame retardant, 0.1 part of antioxidant, 0.2 part of coupling agent and 0.3 part of plasticizer;

[0058] Congo red non-discoloration calcium-zinc stabilizer is a calcium-zinc stabilizer that can withstand heat at 200°C, and the Congo red test paper will not turn blue after 300 minutes; Zinc stabilizer.

[0059] Neoprene CR12...

Embodiment 3

[0074] A heat-resistant wire and cable material used in power lines, comprising the following raw materials in parts by weight: 60 parts of polyvinyl chloride, 40 parts of neoprene CR121, 1.2 parts of dimethyl silicone oil, 8 parts of polypropylene fiber, chlorinated polyvinyl chloride 31 parts of ethylene, 20 parts of nano-silicon carbide, 7 parts of heavy calcium carbonate, 9 parts of nano-active calcium carbonate, 28 parts of trioctyl trimellitate, 6 parts of Congo red-resistant and non-discoloration calcium-zinc stabilizer, heat-resistant 5 parts of color-changing calcium-zinc stabilizer, 5 parts of kaolin, 0.7 parts of PE wax, 0.6 parts of stearic acid, 0.8 parts of flame retardant, 0.3 parts of antioxidant, 0.4 parts of coupling agent and 0.7 parts of plasticizer;

[0075] Congo red non-discoloration calcium-zinc stabilizer is a calcium-zinc stabilizer that can withstand heat at 200°C, and the Congo red test paper will not turn blue after 300 minutes; Zinc stabilizer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com