Ropes carry

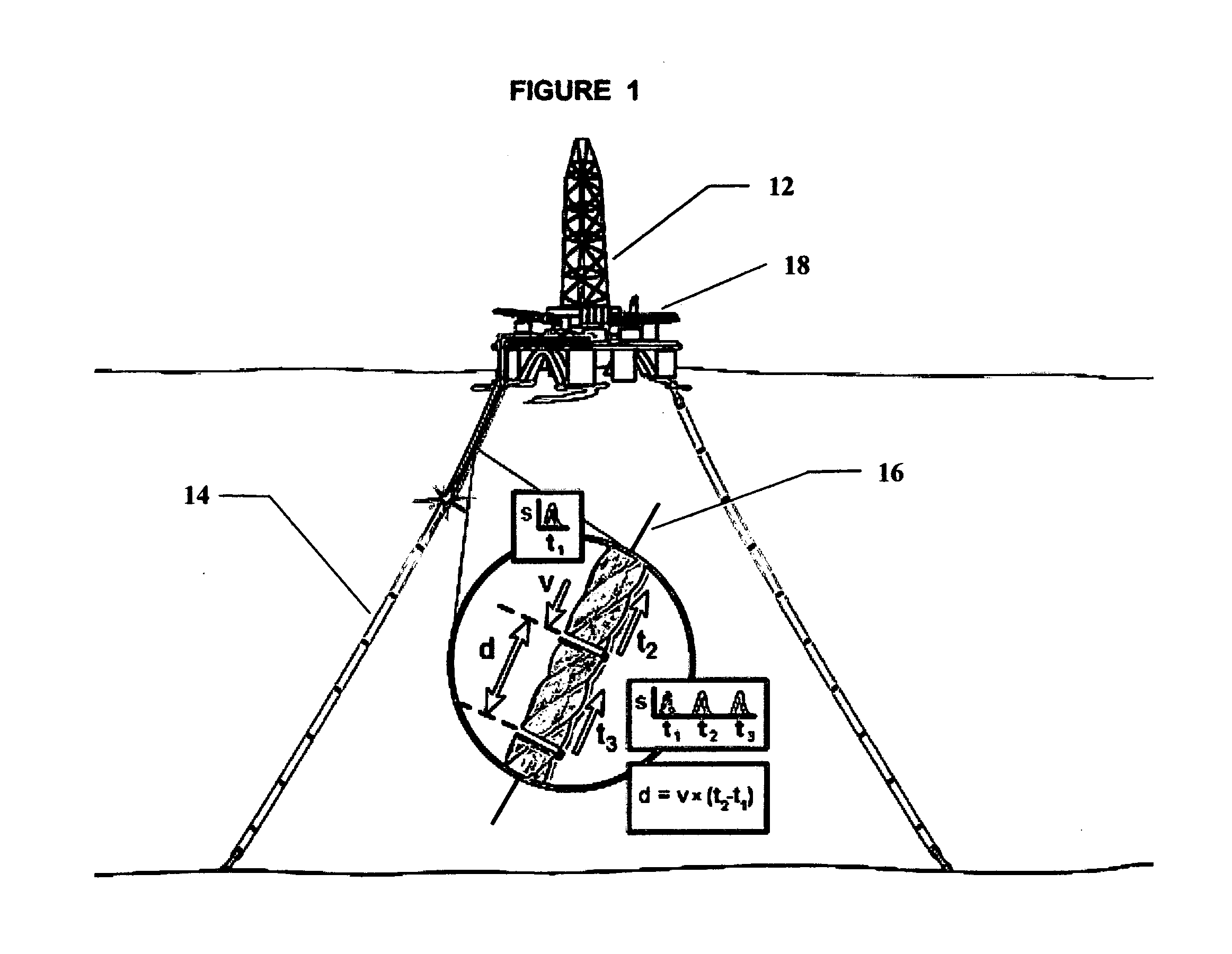

high tension loads and the service environment is often hostile, potentially causing damage to ropes.

The extreme conditions in the marine environment, especially under extreme loading conditions such as hurricanes, and due to possible damage caused by the intrusion of lines and cables from adjacent operations, can reduce the strength of the ropes.

Despite the use of current inspection procedures, however, there have been accidents, damages to property and equipment, injuries and deaths due to unexpected rope failures.

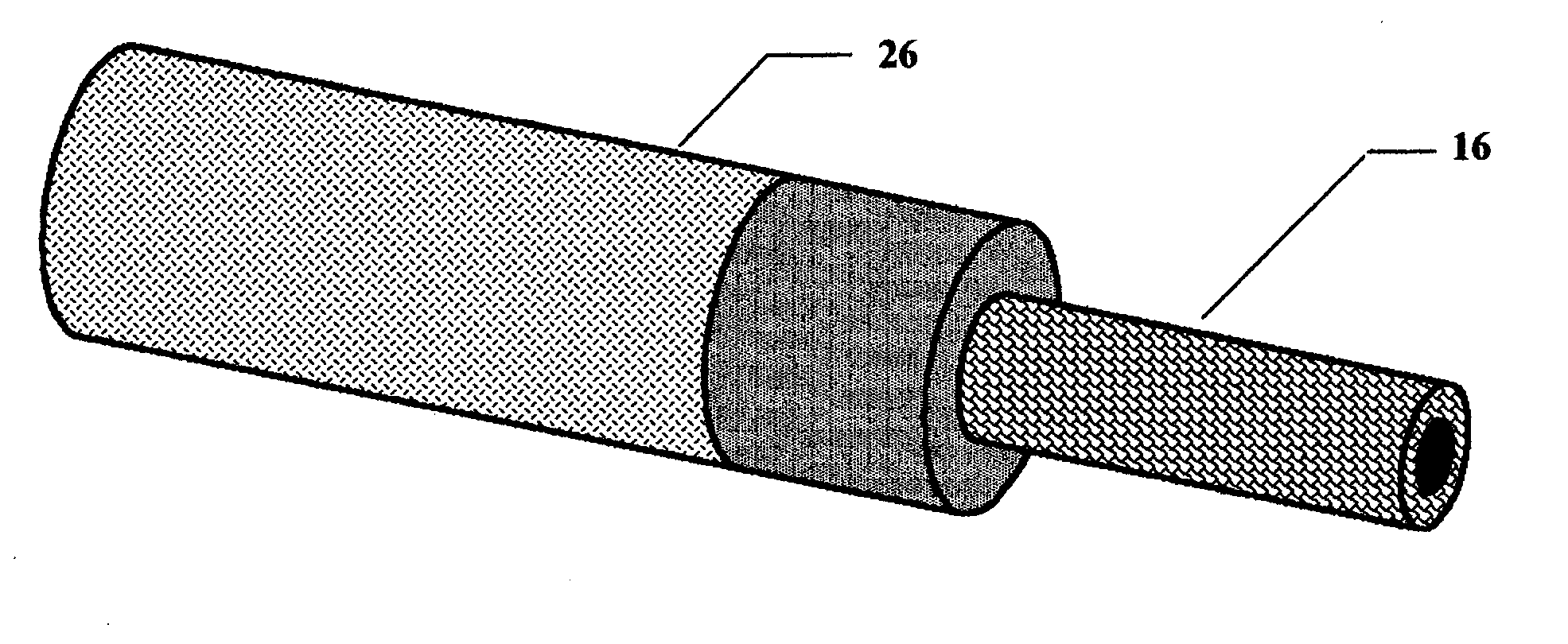

One of the primary challenges is how best to integrate the optical

fiber into the

assembly to insure that the optical fiber experiences the same strain as the

mooring rope and is protected such that it is not damaged during a long service life.

Some resolution problems are inherently characteristic of measurements on

short length specimens characteristic of these lab tests (2-ft), which will not occur for longer length ropes typically used in marine applications.

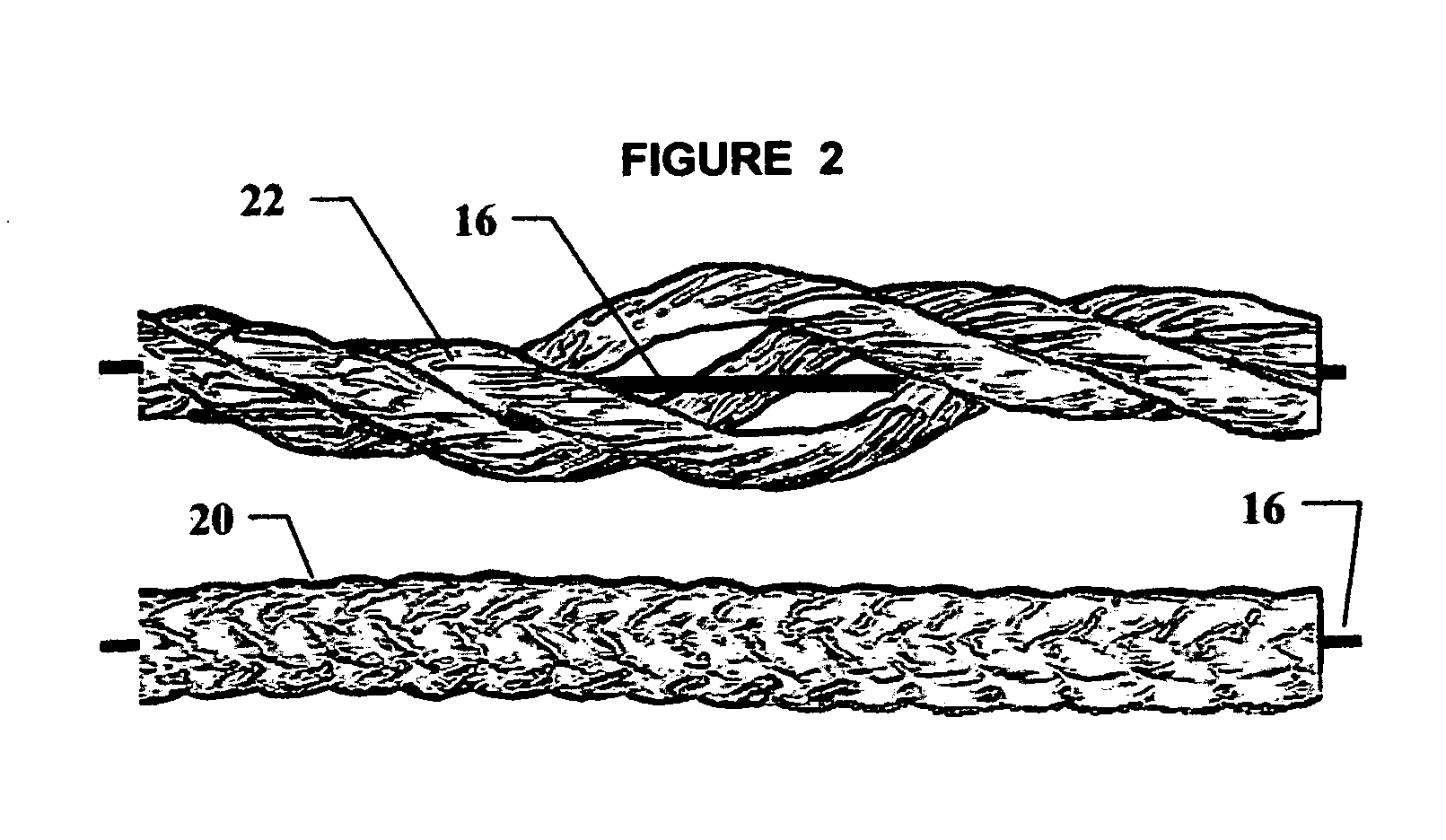

One of the most important discoveries found in these early tests was that a braided jacket with a

braid angle of around 45-degrees surrounding the near axial oriented

polyester fibers was inadequate to locally restrain the plastic optical fiber.

As discussed above, local bending of the optical fiber can create significant attenuation, which limits the fibers ability to transmit light, and consequently the length of rope that can be strain monitored with a single plastic optical fiber.

It was found at very high strains (around 10 percent) that the braided rope imposed small

radius curvature on the optical fiber-plastic cover bundle at the

entry point and caused significant loss of

light signal to the OTDR.

Synthetic fiber mooring ropes segments are limited by transportation and handling to lengths of around 2500 feet.

The practical problem of how to bring the

light signal from remote sections of a long length of rope longer than that permissible by a single plastic optical fiber is still under development.

In time the attenuation characteristics of plastic optical fibers will improve; however, at present, it unlikely that a single plastic optical fiber will have sufficient limited light loss to be able to monitor a length of 10,000 feet or more.

First, glass optical fibers can be used which have lower attenuation, but as noted above, glass optical fibers cannot directly bridge the long length because strains typically imposed exceed the breaking strain of glass fibers.

This is cumbersome requiring power at ocean depths and has practical limitations.

OTDR

instrumentation could be located remotely and transmit the data rather than the

light signal to the surface, but this would impose severe complications.

This approach is being conducted because no

strain measurement or other

system is available to provide more definitive in situ inspection.

The method taught in U.S. Pat. No. 5,182,779 is not applicable to the

direct measure of

large strain in ropes because the small ultimate strain capability of glass optical fibers does not allow it.

Although glass fibers have an ultimate strain capability on the order of 2 percent, practical limitations impose a

strain limit of less than 1 percent.

Bridge and

elevator cables are typically steel

wire rope and as such the design strain is normally limited to less than 0.2 percent (60,000 psi stress) and if constructed of

synthetic fiber have practical deformation limitations and associated low strains.

The method is thus limited to measurement in metallic and composite structures experiencing small strains.

The prestressing approach is not practical for

mooring ropes used to maintain position in offshore platforms and the inventors do not teach how to use the technique without overstressing the glass optical fiber even for small strains.

Patent 5,182,779 cannot serve the purposes of measuring large strains in ropes such as experienced in service by ropes using in the

marine industry including offshore platform mooring ropes.

Measurement of local strains in typical metallic and composite structures using straight glass optical fibers and OTDR instrumentation is not practical because of the extremely low sensitivity of the OTDR method when used for short gage lengths.

In addition, typical strains in a rope are an

order of magnitude larger than strains in typical metallic or composite structures making glass optical fibers unacceptable.

The telecommunication industry uses glass optical fiber because the attenuation of plastic fibers over long lengths would be unacceptable.

The patent teaches these uses for glass optical fiber, but does not address the use of plastic optical fiber or measuring strain in ropes.

The deficiency of the

visual inspection method is that it reveals nothing about the load-strain history of the rope or the state of internal wear or degradation.

For such large ropes, one cannot visually detect internal wear or damage.

In addition, it is difficult to reliably inspect long length mooring ropes in situ using, for example, ROV technology.

The short rope segment removal and testing method for determining “fitness for service” of mooring ropes used for

station keeping of offshore platforms is an expensive operation and the removal activity itself introduces operational hazards.

The

short length rope test segments thus can provide a weaker link than the longer length segments which constitute the remainder of the rope, and their introduction can thus reduce the overall strength of the rope in service.

This is a large inclusion which interferes with the architectural design of the rope and whose presence could affect the mechanical properties of the rope.

More importantly, the indirect measurement of strain is much less accurate and conclusive than the direct measurement of strain in the mooring rope permitted by the

large strain capability of plastic optical fibers described herein.

Although the developers claim that the technique can detect local damage, the magnitude of the local strain is not measured.

Login to View More

Login to View More