Micro-fluidic chip containing sample pre-treatment film and production method therefor

A sample pretreatment, microfluidic chip technology, applied in the preparation of test samples, instruments, measuring devices, etc., can solve the problems of complex micromachining and operation methods, low pretreatment efficiency, high cost, and achieve detection selectivity and improved analytical sensitivity, simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

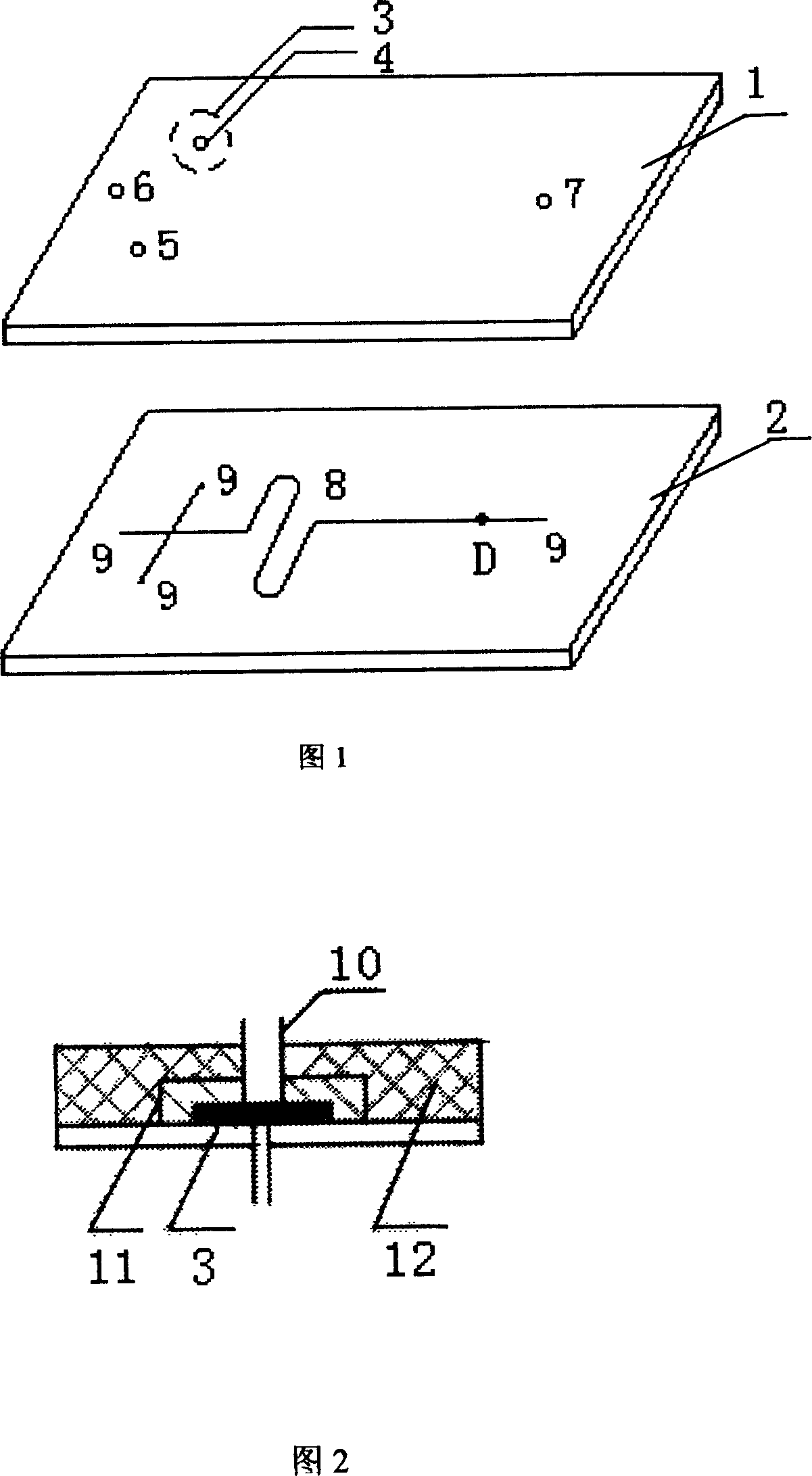

[0018] Example 1: Microfluidic chip containing sample pretreatment membrane

[0019] Modification method of polyamide membrane 3: take 10 polyamide membranes with a diameter of 5mm, and put them in 2.5mol L at 30°C -1 Activated in HCl solution, the activated membrane is washed with distilled water: then, add the dye Cymbal blue F-3GA and the activated polyamide membrane in a closed container, and react at 60°C for 30 minutes, then add NaCl to accelerate the dye deposition on the film. After continuing to react for 30min, add Na 2 CO 3 , heated up to 80°C, and reacted for 4 hours. During the reaction process, the reaction solution was continuously oscillated to make the ligand bonding on the surface of the membrane uniform. After the reaction, the dye-coupled polyamide membrane was cleaned with 80% ethanol and distilled water until there was no dye in the cleaning solution, and then the membrane was removed. Store in acetic acid-sodium acetate buffer solution containing 0.0...

Embodiment 2

[0023] Example 2: Detection application of microfluidic chip containing sample pretreatment membrane

[0024] Will contain 0.10μg·mL -1 The serum sample of dobutamine hydrochloride is injected from the injection pump through the capillary, and the chemiluminescent reagent KMnO 4 With Luminol (both concentrations are 2.0×10 -6 mol L -1 ,) reagents are introduced into the chip from the liquid guide holes 5 and 6 respectively, and after the two are mixed through the cross-shaped intersection point, a chemiluminescence reaction occurs, and a chemiluminescence signal is obtained from the detection window D. Through the comparison of the luminescence results, it can be seen that after passing through the pretreated affinity membrane, the chemiluminescence signal response sensitivity of dobutamine hydrochloride is about 2.10 times higher than that of the injection without the membrane, compared with five times on the microfluidic chip. The measured relative standard deviation RSD,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com