Nickel oxide electrochromic film and preparation method thereof

An electrochromic, nickel oxide technology, applied in nickel oxide/nickel hydroxide, nanotechnology and other directions, can solve the problems of reducing discoloration effect, limited reaction area, long diffusion time, etc., to enhance electrochemical activity and ensure fast Motion, the effect of increasing the mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cleaning ITO glass:

[0024] The ITO glass was first cleaned with chloroform for 30 minutes, then ultrasonically cleaned with a mixed solution of isopropanol and acetone with a volume ratio of 1:1, then ultrasonically cleaned with absolute ethanol, finally cleaned with deionized water, and dried to obtain the cleaned glass. ITO glass.

[0025] To prepare the polymer solution:

[0026] A block copolymer polymethyl methacrylate-b-polystyrene (PMMA-b-PS) with an average molecular weight of 263,000 and a homopolymer polymethyl methacrylate (PMMA) with an average molecular weight of 15,000 were dissolved in toluene Forming the solution that the total mass percentage of polymer is 2%, wherein, the quality of polymethyl methacrylate (PMMA) is 10% of the quality of polymethyl methacrylate-b-polystyrene (PMMA-b-PS) .

[0027] Preparation of copolymer nanoporous templates on ITO:

[0028] The polymer solution prepared above was spin-coated on the cleaned ITO glass, the spin-c...

Embodiment 2

[0039] Take the same preparation method as Example 1, its difference is only:

[0040] In preparing the polymer solution, the mass of polymethyl methacrylate (PMMA) is 20% of the mass of polymethyl methacrylate-b-polystyrene (PMMA-b-PS).

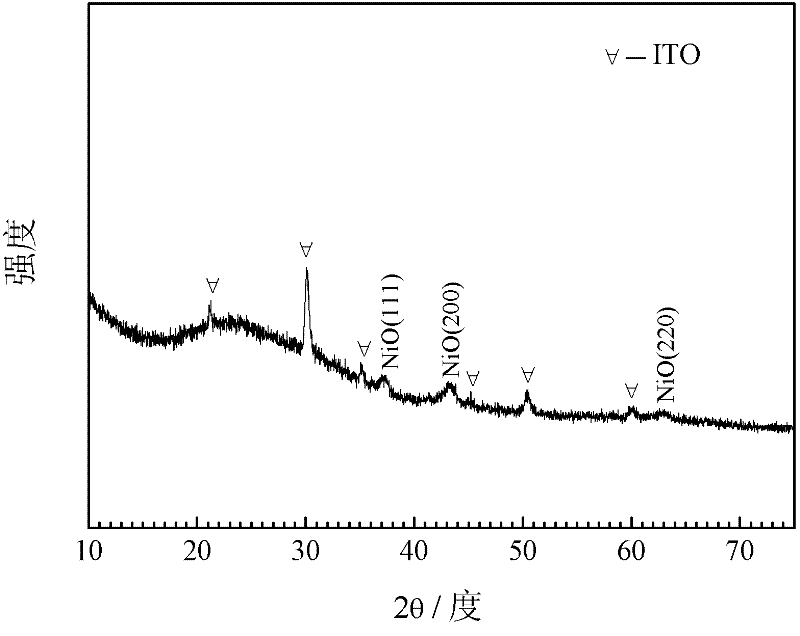

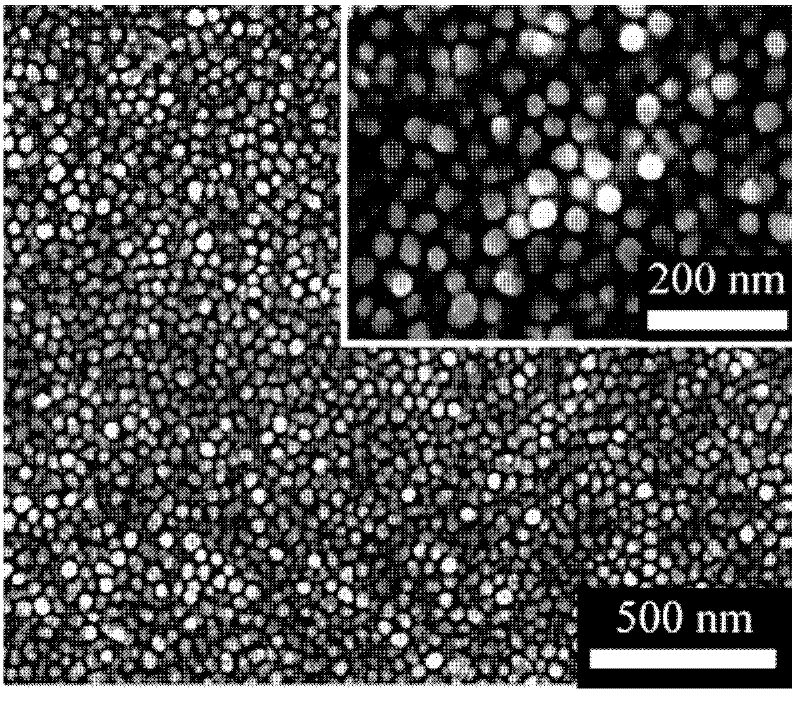

[0041] XRD and SEM tests were carried out on the final product, and the results showed that the composition was NiO with good crystallization, the surface of the film was NiO nanowire array, the length of NiO nanowire was 100-200nm, and the average diameter of nanowire was about 54nm.

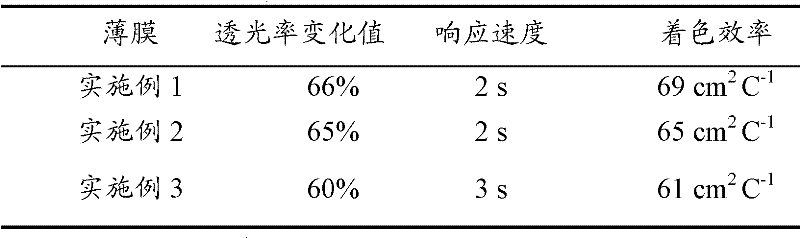

[0042] The same method as in Example 1 was used to test the electrochromic performance of the final product. In a 0.1 mol / liter KOH solution, 0.65V and 0V square pressure were applied respectively, and the NiO nanowire array film was between transparent and brown. reversible change. Detect its light transmittance change value in the 300-1000nm band, and at the same time use the light transmittance response change at λ=600nm to detect the electrochromic speed...

Embodiment 3

[0045] Take the same preparation method as Example 1, its difference is only:

[0046] In preparing the polymer solution, the mass of polymethyl methacrylate (PMMA) is 30% of the mass of polymethyl methacrylate-b-polystyrene (PMMA-b-PS).

[0047] XRD and SEM tests were carried out on the final product, and the results showed that the composition was NiO with good crystallization, the surface of the film was NiO nanowire array, the length of NiO nanowire was 100-200nm, and the average diameter of nanowire was about 65nm.

[0048] The same method as in Example 1 was used to test the electrochromic performance of the final product. In a 0.1 mol / liter KOH solution, 0.65V and 0V square pressure were applied respectively, and the NiO nanowire array film was between transparent and brown. reversible change. Detect its light transmittance change value in the 300-1000nm band, and at the same time use the light transmittance response change at λ=600nm to detect the electrochromic speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com