A high power density flow battery

A high power density, flow battery technology, used in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as insufficient use of electrolyte, difficulty in improving power density, and easy occurrence of dead zone distribution, and improve battery operation. Efficiency, reducing ohmic internal resistance, and the effect of large internal and external hydraulic pressure differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

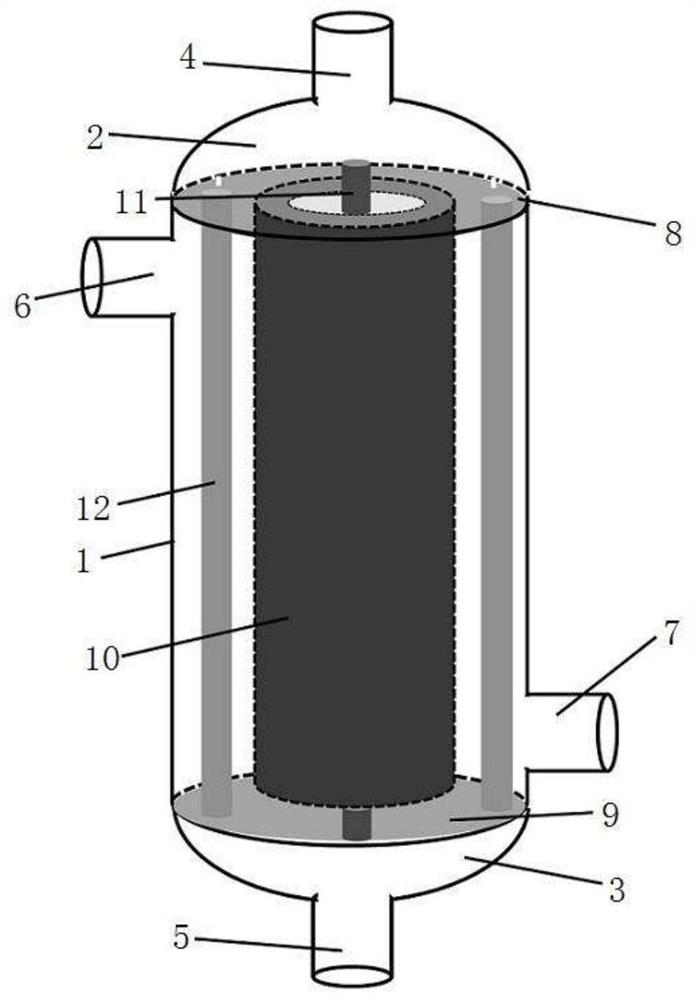

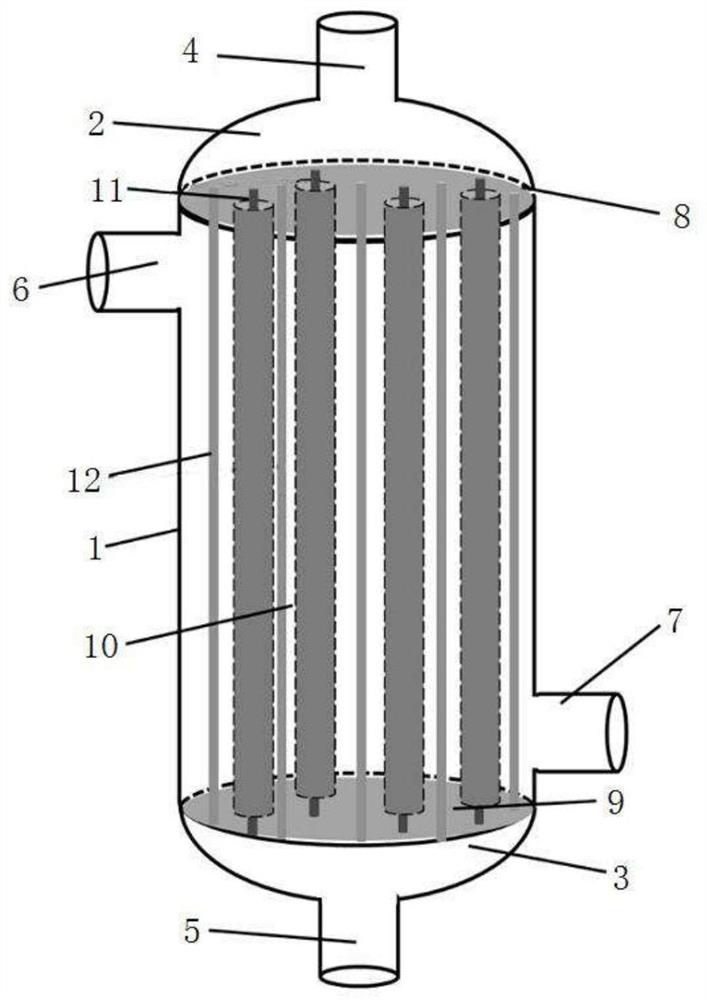

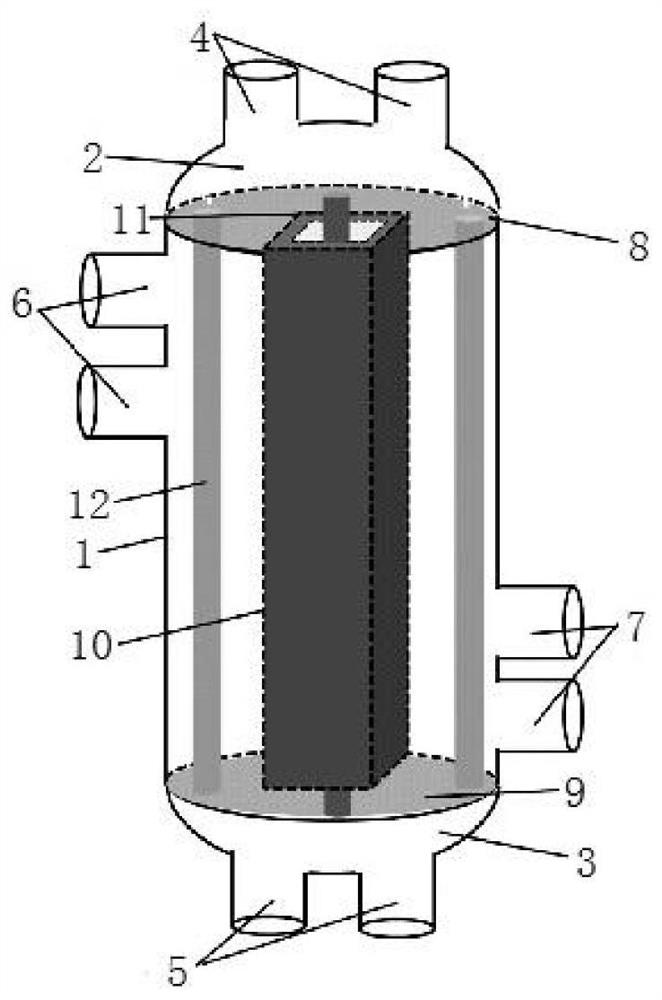

[0018] Such as figure 1 , for a single-tube membrane zinc-bromine flow battery, a hollow separation membrane 10 is placed inside the cylinder body 1, and the two ends of the hollow separation membrane 10 are respectively connected to the upper end seal 8 and the lower end seal 9, wherein the upper end seal 8 and the lower end seal 9 Connect the inside of the cylinder 1 with the outside of the hollow separation membrane 10, the two ends of the cylinder 1 are respectively connected with the upper head 2 and the lower head 3, wherein the upper head 2 has a first electrolyte inlet 4, and the lower head 3 has a There is a first electrolyte outlet 5, a positive or negative first electrode 11 is located inside the hollow separation membrane 10, and two corresponding positive or negative second electrodes 12 are located outside the hollow separation membrane 10 and inside the cylinder 1, and the hollow separation The membrane 10 is a tubular separation membrane. There is a second ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com