A kind of vanadium nitride nanosheet flexible composite electrode material and its preparation method and application

A vanadium nitride nano-composite electrode technology, which is applied in the direction of nitrogen compounds, chemical instruments and methods, and hybrid capacitor electrodes, can solve the problems of poor capacitance performance and cycle stability of supercapacitors, and achieve improved utilization of active materials and good capacitance. performance, excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

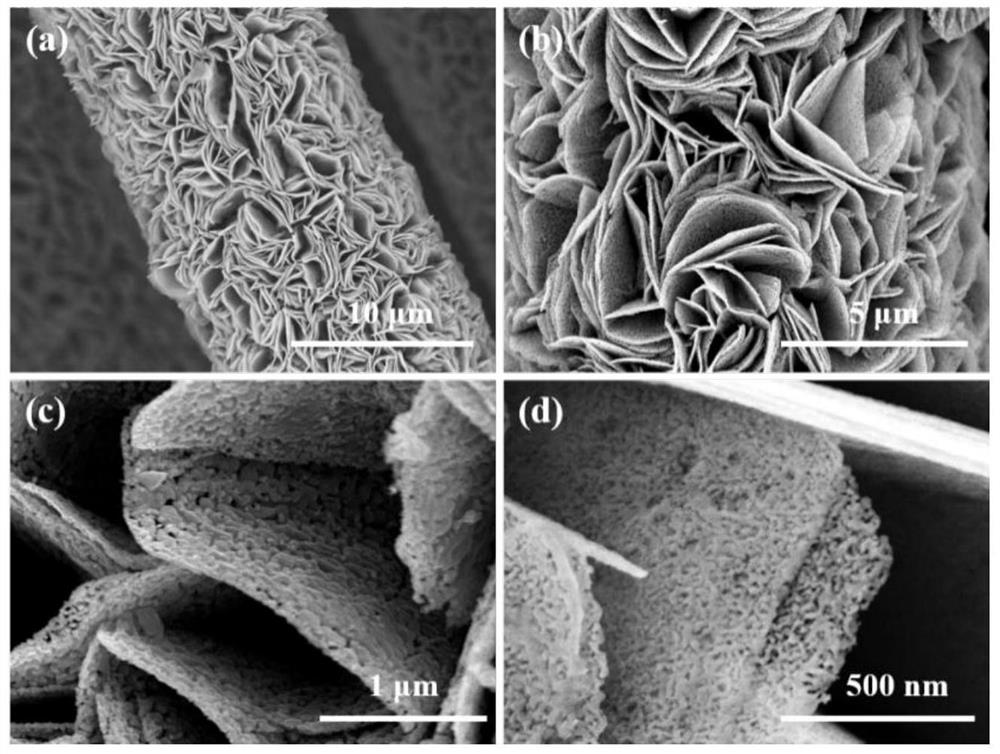

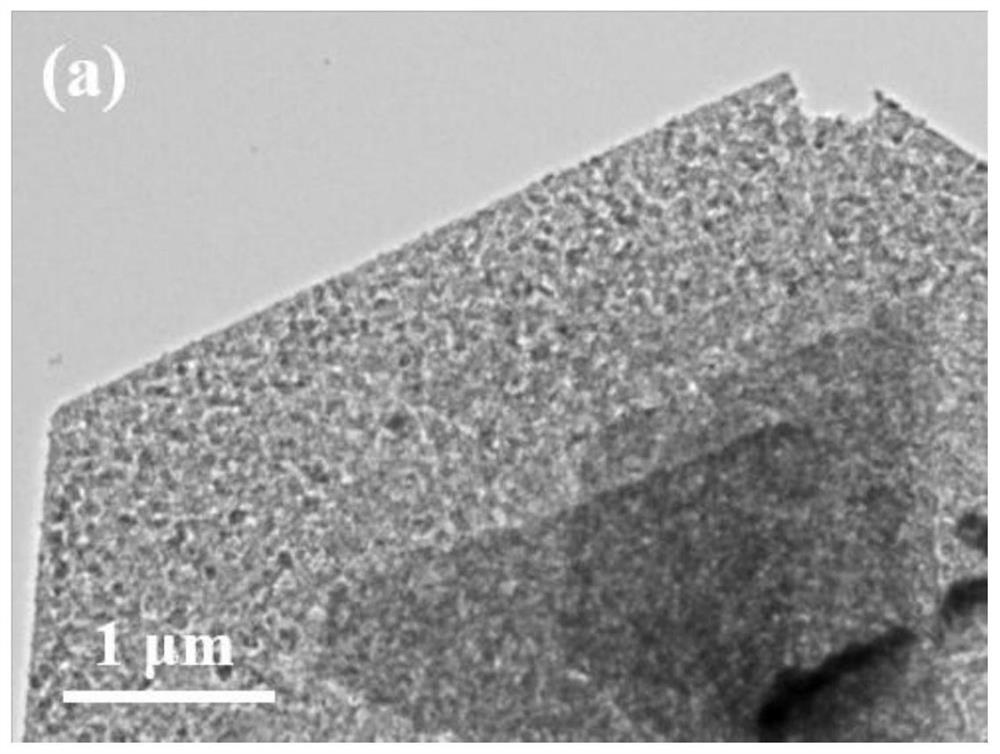

[0039] A flexible composite electrode material of vanadium nitride nanosheets, with carbon cloth as the substrate, vanadium nitride uniformly grows on the carbon cloth fibers and forms a porous nanosheet layer with a three-dimensional structure on the surface of the carbon cloth fibers, in which vanadium nitride grows The diameter of a single carbon cloth fiber in the nano sheet layer is 15-20 μm, and the thickness of the vanadium nitride nano sheet flexible composite electrode material is 0.35-0.5 mm.

[0040] Transition metal nitrides have similar electrochemical properties to ruthenium oxide and can exhibit high capacitance at high scan rates due to their high electrical conductivity and fast reversible redox process. Among them, vanadium nitride has a high specific capacitance—1340F / g -1 , Excellent conductivity—1.67×10 6 S / m and wide electrochemical window, it is a very potential anode material for supercapacitors, which is expected to replace commercial electrode materi...

Embodiment 2

[0043] A preparation method of vanadium nitride nanosheet flexible composite electrode material, comprising the steps of:

[0044] Step 1. Preparation of vanadium sulfide / carbon cloth precursor:

[0045]Prepare thioacetamide, deionized water, ammonia water and ammonium metavanadate according to a certain molar volume ratio, add thioacetamide to deionized water, stir until thioacetamide is completely dissolved, add ammonia water and ammonium metavanadate in turn, Continue stirring at a certain stirring speed for a certain period of time to obtain a mixed solution, and pour the mixed solution into a high-pressure reactor for subsequent use;

[0046] Fix the carbon cloth on the polytetrafluoroethylene sheet and put it into the autoclave, seal the autoclave and raise the temperature from room temperature to 160°C within a certain period of time. Rinse with water and ethanol, and dry the cleaned sample to obtain the vanadium sulfide / carbon cloth precursor;

[0047] Step 2. Prepar...

Embodiment 3

[0050] A preparation method of vanadium nitride nanosheet flexible composite electrode material, comprising the steps of:

[0051] Step 1. Preparation of vanadium sulfide / carbon cloth precursor:

[0052] Prepare thioacetamide, deionized water, ammonia water and ammonium metavanadate according to the molar volume ratio of 12~16mmol:35mL:2mL:2mmol, wherein thioacetamide, ammonia water and ammonium metavanadate are of analytical grade, with a purity> 99.0%;

[0053] Add thioacetamide into deionized water, stir until thioacetamide is completely dissolved, add ammonia water and ammonium metavanadate in turn, and continue stirring at a stirring speed of 100-500r / min for 40-60min to obtain a mixed solution. During the stirring process , the color of the solution changes from white to yellow and then gradually turns black, and the mixed solution is poured into a high-pressure reactor for subsequent use;

[0054] Use Teflon tape to fix the 1cm×3cm carbon cloth on the polytetrafluoroe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

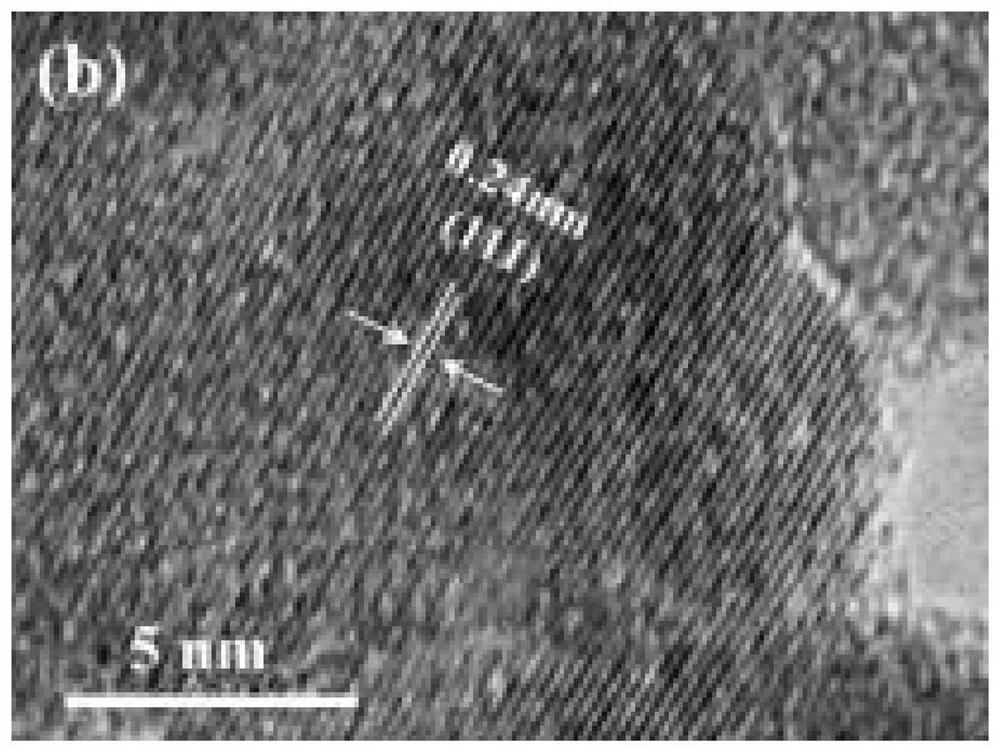

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com