Kitchen waste separation and solid matter drying and sterilization device

A technology of kitchen waste and sterilization device, which is applied in the direction of waste drying, heating device, drying solid materials, etc., can solve problems such as affecting urban appearance and living environment, and affecting people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

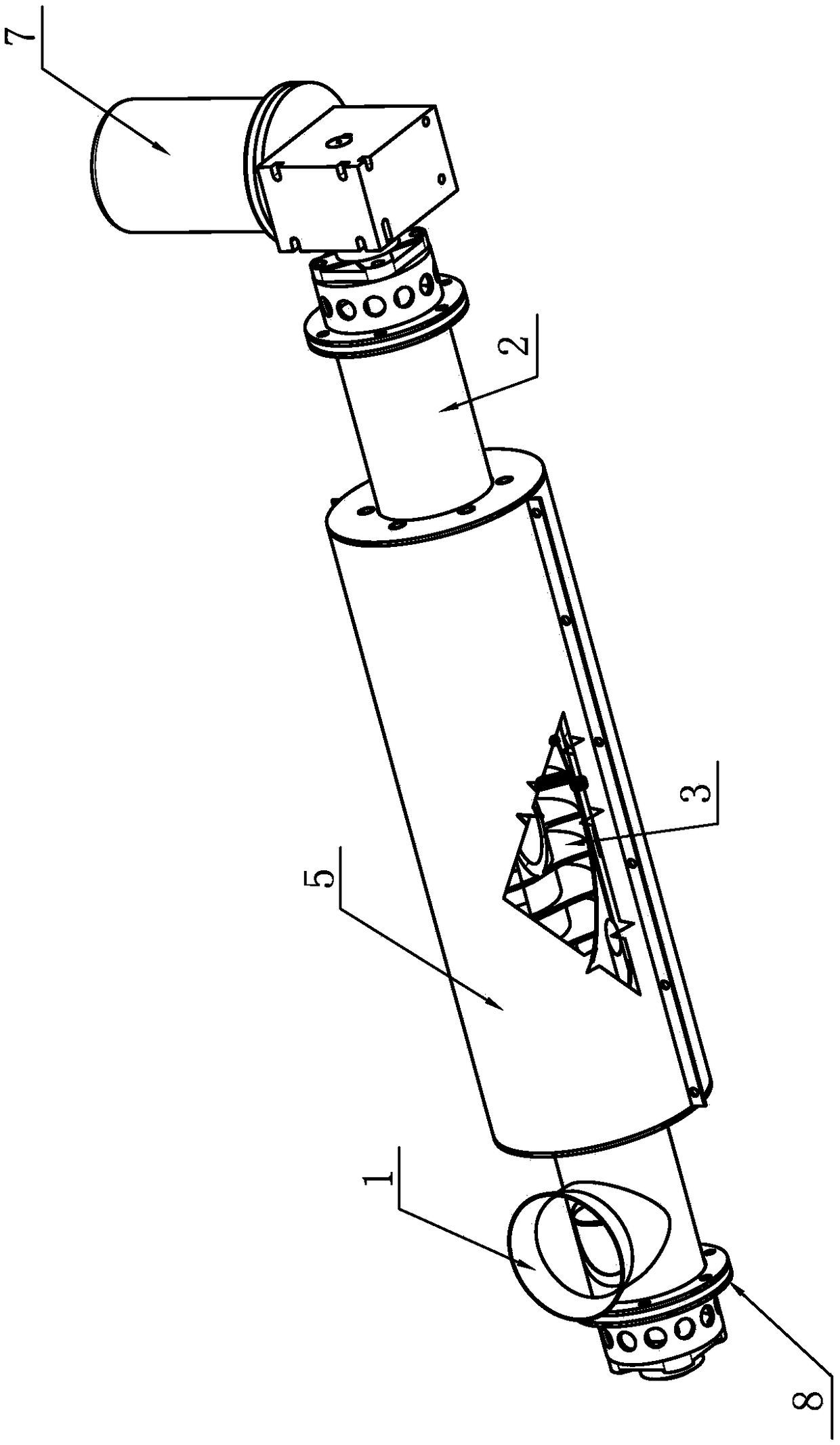

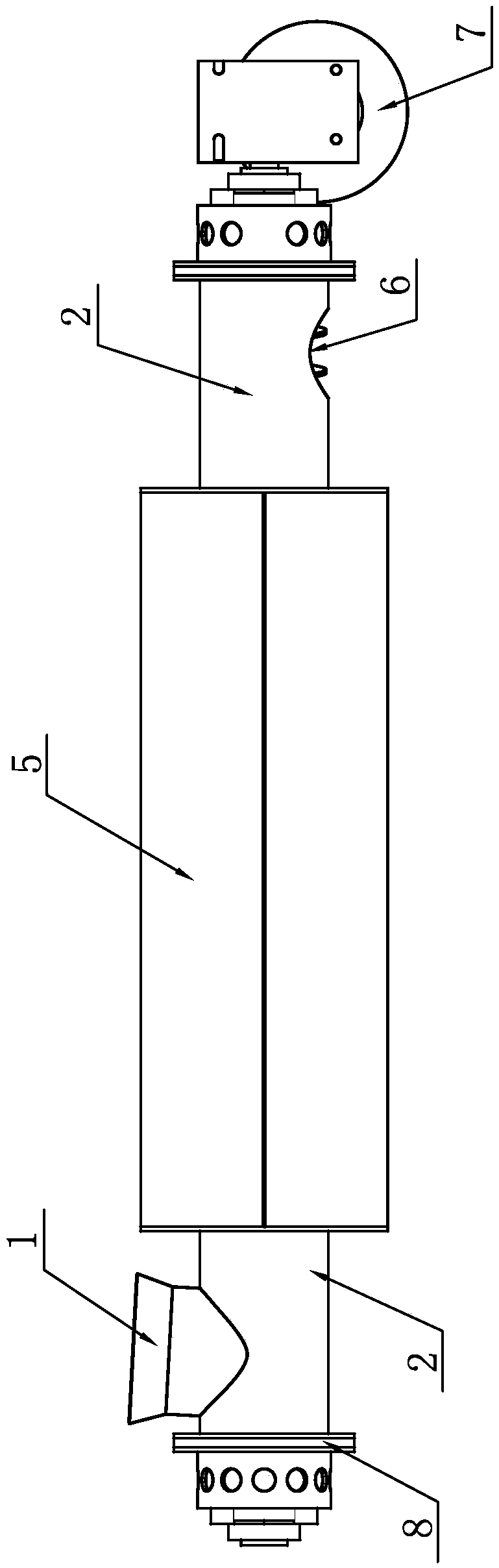

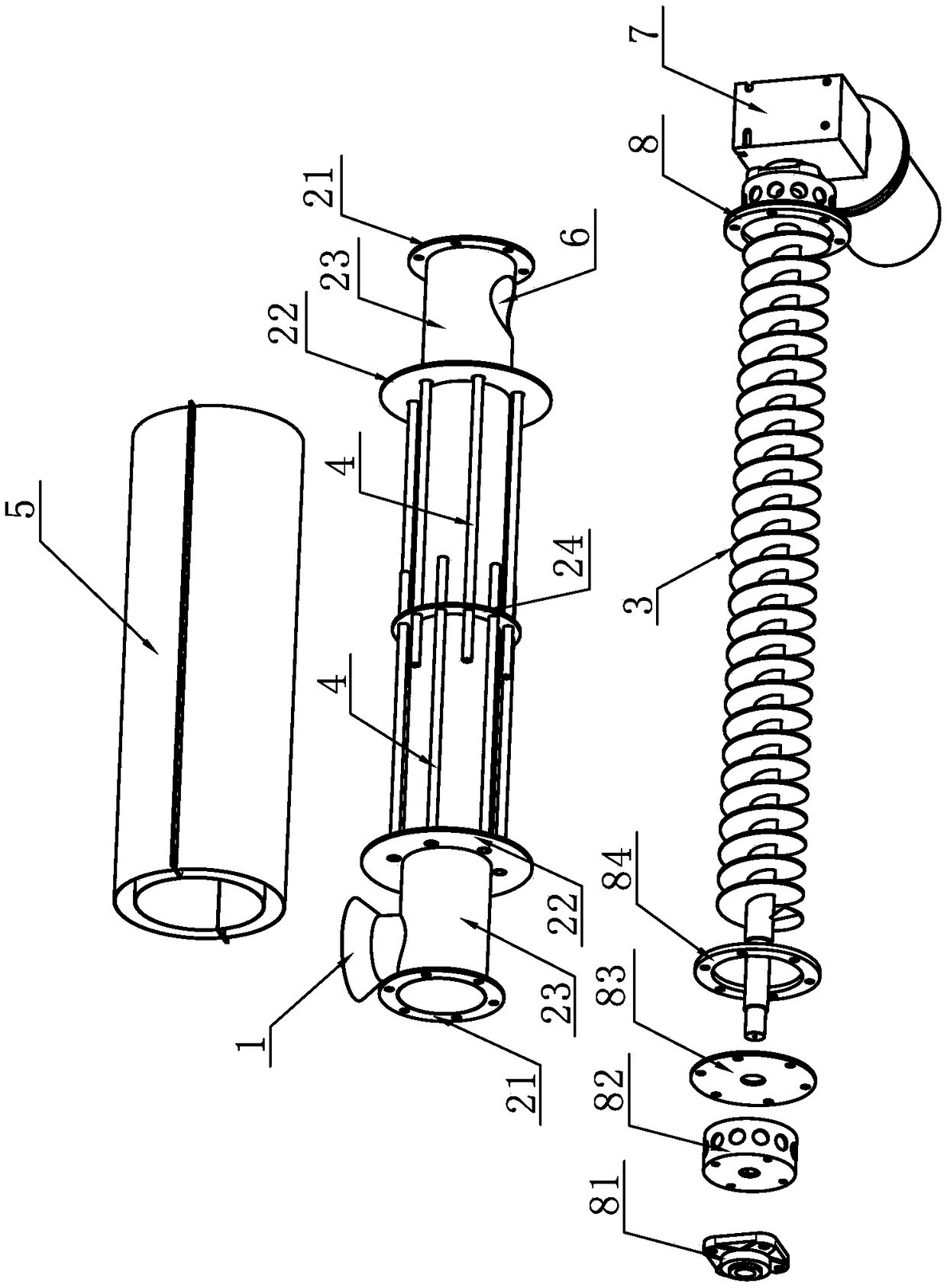

[0019] Embodiment 1: A kind of food waste separation solid matter dry sterilization device, such as Figure 1-Figure 3 As shown, it includes a feed pipe 1, a feed pipe 2, a screw hinge dragon 3, a heating element 4, a thermal insulation pipe 5, a drying outlet 6, a hinge dragon driving device 7 and an end cover seat 8. The pipe 2 includes an end face connection flange 21, an insulation tube connection flange 22, a pipe body 23 and a support ring 24. On the heating section, the supporting ring 24 is arranged between the connecting flanges 22 of the two insulating cylinders, the heating element 4 is installed on the connecting flange 22 and the supporting ring 24 of the insulating cylinder, and the heat insulating tube 5 is installed on the connecting flanges of the two insulating cylinders 22, the heating unit 4 is located between the thermal insulation pipe 5 and the feeding pipe 2, the feeding pipe 1 is arranged at the feeding end of the feeding pipe 2, and the drying outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com