Forming method of trackless lampshade and forming mould

A molding method and molding die technology, applied in the field of lighting equipment, can solve the problems of unavoidable welding points, material strength reduction at welding lines, large flow resistance, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

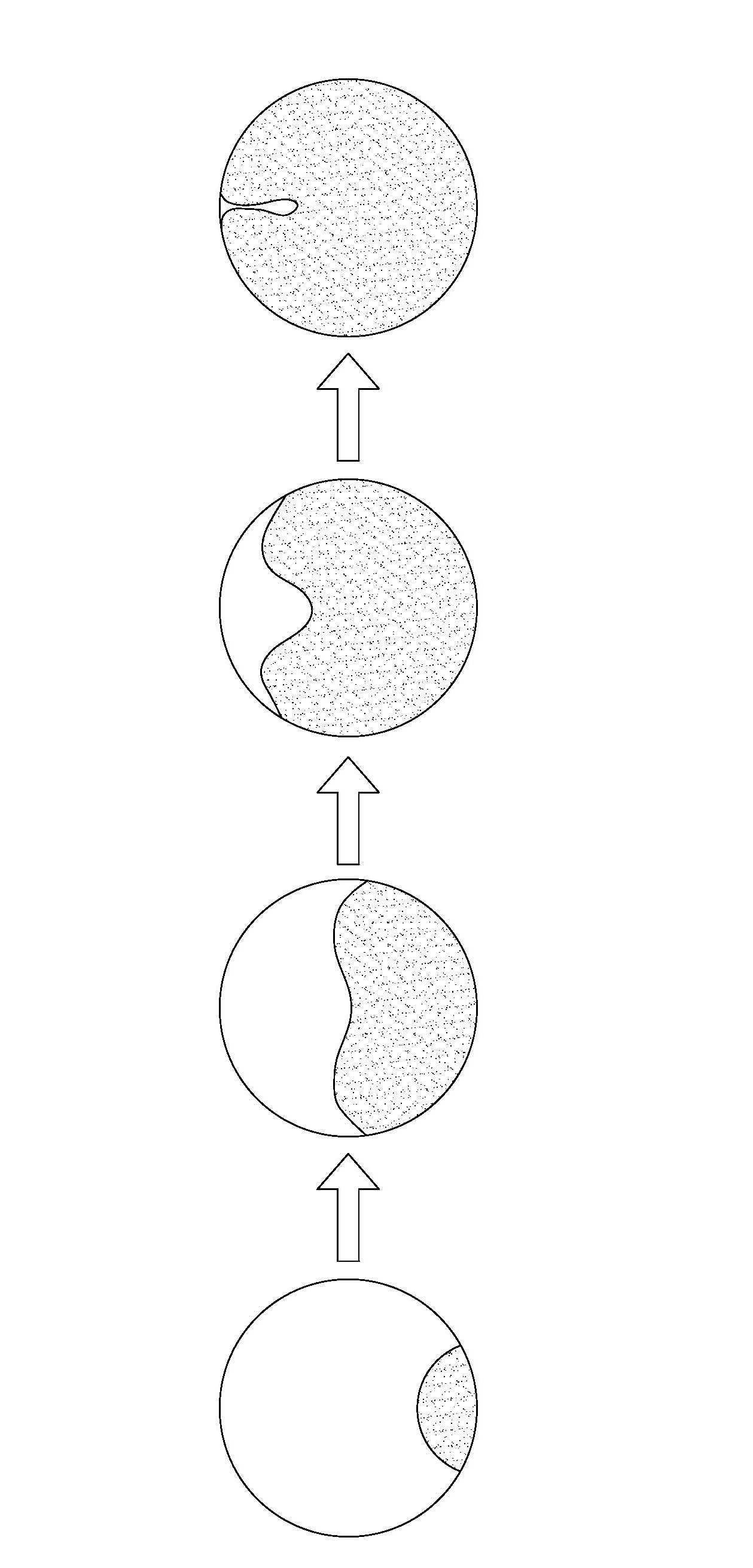

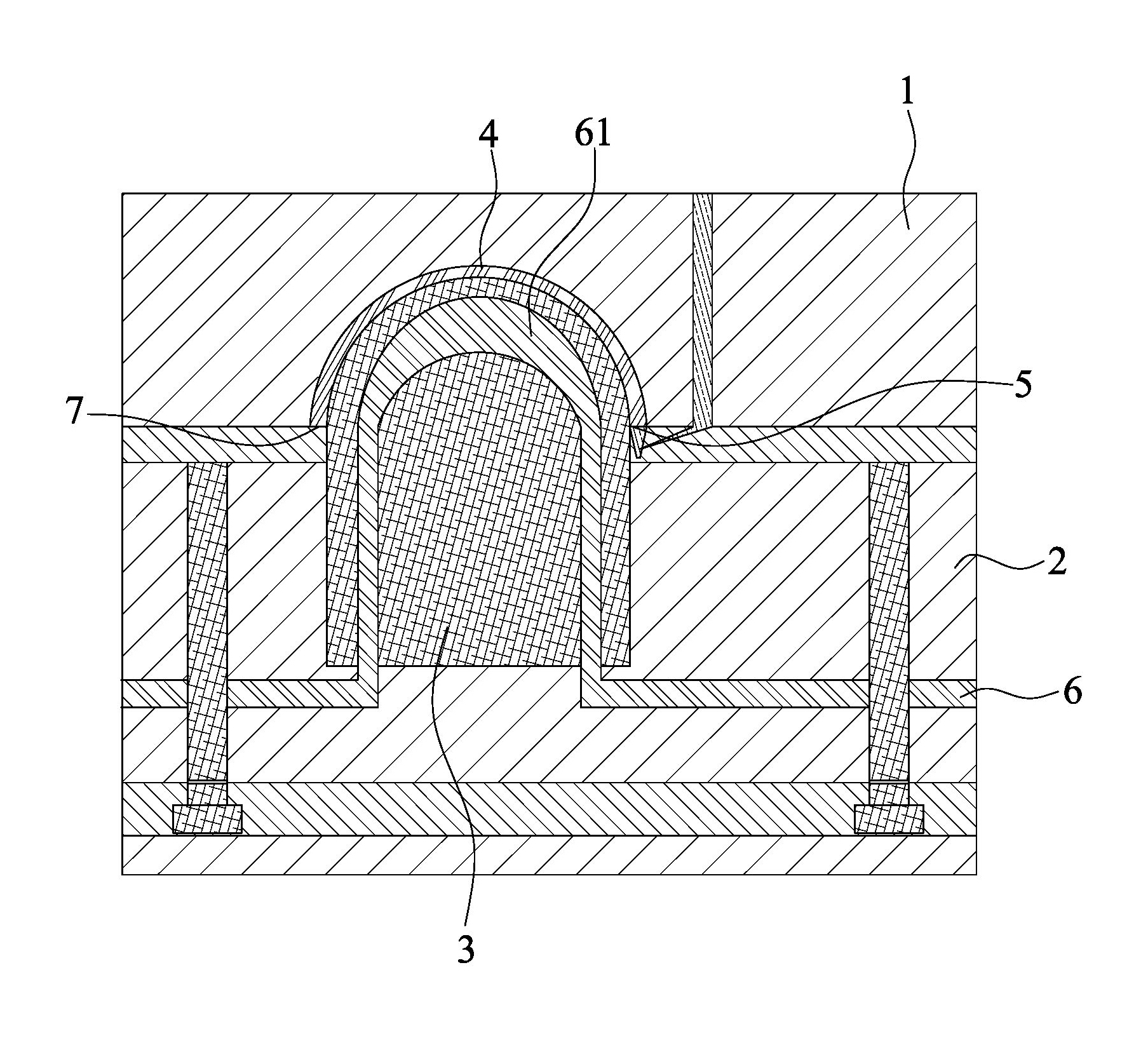

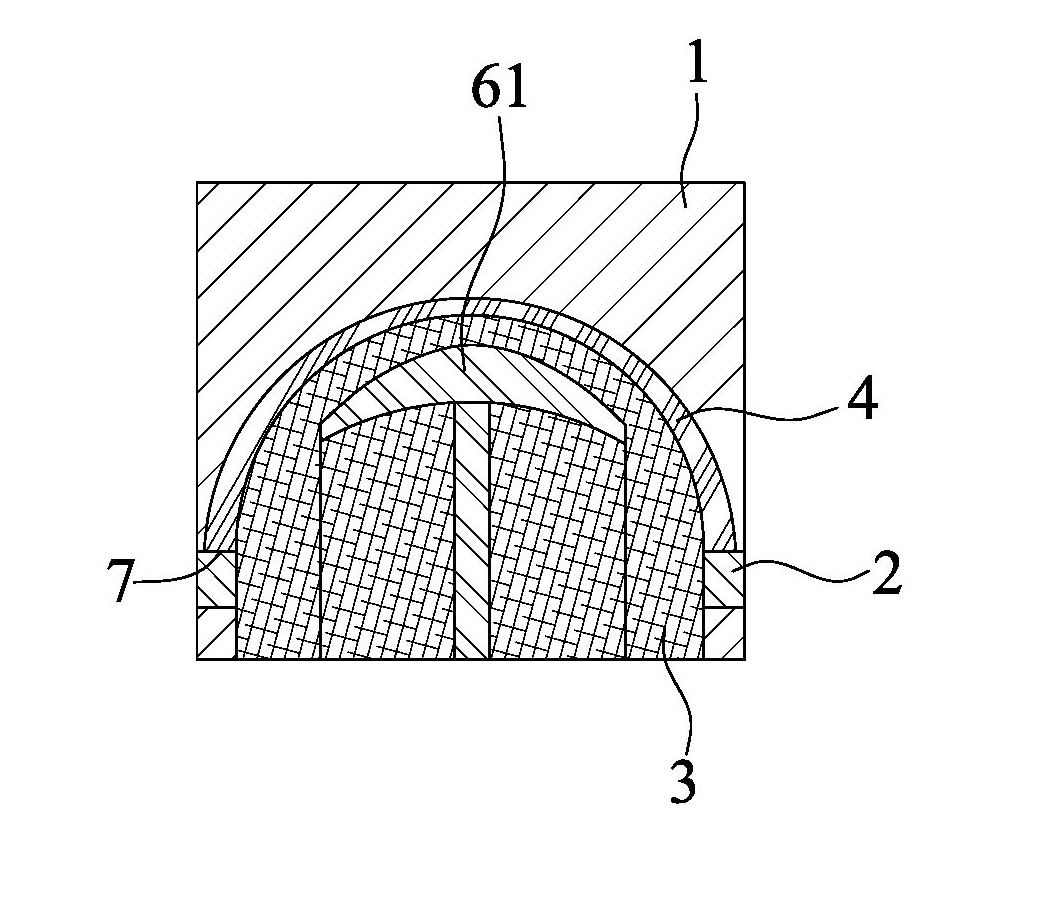

[0021] The invention discloses a method for forming a seamless lampshade. The steps of the method are: setting a cavity in the mold in the shape of the opposite injection part, using the edge of the opening of the opposite injection part as the parting surface, and A feed inlet is set at a certain position, and the melted material is injected into the cavity of the mold from the feed inlet. During the injection process, the cavity is locally heated. The heating position is at the point where the forward resistance of the material is the largest. When the forward resistance is the same, then At the point where the front material travels the longest from the feed port to the parting surface, the front material in all positions is gathered at the parting surface, and finally forms a seamless injection part. The molding process of injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com