Epoxidized soybean oil modified collagen fiber as well as preparation method and application thereof

A technology of epoxidized soybean oil and collagen fibers, which is applied in the direction of repelling fibers to liquids, fiber processing, animal fibers, etc., can solve the problems of weak interlayer performance, migration and high cost of reinforced polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The first embodiment of the present invention provides a preparation method of epoxidized soybean oil modified collagen fibers, comprising the following steps:

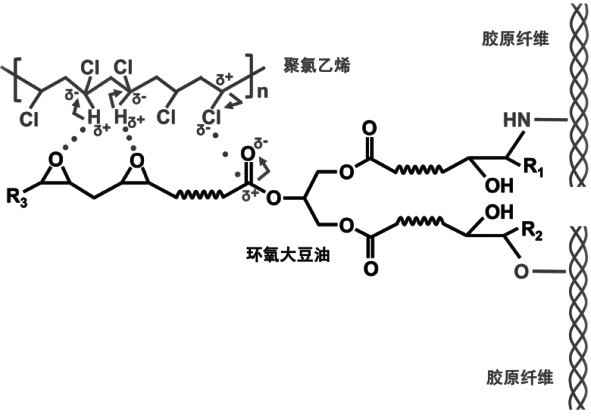

[0033] The pretreated collagen fibers were subjected to a ring-opening grafting reaction at 80-140 °C for 4-12 h with a solution containing epoxidized soybean oil and a catalyst.

[0034] Activated pretreated collagen fibers will expose more -NH 2 , -OH, -COOH and other groups, part of the epoxy groups on the flexible long chain of epoxy soybean oil molecules ( ) can be ring-opened at 80-140 °C in the presence of a catalyst, and with -NH on the side chain of collagen fibers 2 , -OH, -COOH and other groups react to form , , The grafted structure effectively covers the surface of collagen fibers, reduces the surface free energy of collagen fibers, and realizes the hydrophobic modification of collagen fibers.

[0035] It should be noted that epoxidized soybean oil can also modify plant fibers, but compared...

Embodiment 1

[0078] The present embodiment provides a kind of preparation method of epoxidized soybean oil modified collagen fiber, comprises the following steps:

[0079] (1) Add the waste leather shavings after washing to deionized water, adjust the pH to 8 with sodium bicarbonate powder, filter after washing and dehydrate with ethanol. Grinding with a pulverizer, passing through a 40-mesh sieve to obtain collagen fibers;

[0080] (2) Take 10 parts by weight of collagen fibers obtained in step (1) after pulverization, and add in 100 parts by weight of isopropanol solvent containing 10 parts by weight of epoxy soybean oil and 4 parts by weight of catalyst tetrabutylammonium bromide in advance, Stir at 90 ° C for 6 h; filter and discharge the material and place it in an oven at 80 ° C for 12 h; because isopropanol and epoxidized soybean oil form an azeotrope, the boiling point increases, so under the experimental conditions, the stirring temperature can be higher than The boiling point of...

Embodiment 2

[0084] The present embodiment provides a kind of preparation method of epoxidized soybean oil modified collagen fiber, comprises the following steps:

[0085] (1) Add the waste leather shavings after washing to deionized water, adjust the pH to 5 with sodium bicarbonate powder, filter after washing and dehydrate with ethanol. Grinding with a pulverizer, passing through a 100-mesh sieve to obtain collagen fibers;

[0086] (2) Take 10 parts by weight of the pulverized collagen fibers obtained in step (1), and add them to 120 parts by weight of isopropanol solvent containing 10 parts by weight of epoxy soybean oil and 4 parts by weight of catalyst anhydrous tin tetrachloride in advance , stirred at 95 °C for 5 h. Place in 90 ° C oven for 10 h after filtering the discharge;

[0087] (3) Stir and wash the solid fibers obtained in step (2) with isopropanol for 1.5 h, repeat stirring and washing twice to remove unreacted excess epoxidized soybean oil;

[0088] (4) Dry the solid fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com