A kind of superhydrophobic microcapsule polymer cement-based anticorrosion coating and its preparation method and application

An anti-corrosion coating and microcapsule technology is applied in the field of cement anti-corrosion coatings to achieve the effects of improving waterproof and impermeability, preventing infiltration, and improving waterproof and impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0065] A preparation of superhydrophobic microcapsule polymer cement-based anticorrosion coating, comprising the following methods:

[0066] 1. Preparation of hydrophobically modified graphene oxide:

[0067] 1.1 Add 5 parts by weight of graphene oxide into 150ml of absolute ethanol, and then ultrasonically disperse for 2 hours to obtain a graphene oxide dispersion.

[0068] 1.2 Add 7 parts by weight of polyperfluoroalkylsiloxane to the graphene oxide dispersion, adjust the reaction temperature at 65°C for 24 hours, and vigorously stir at a rate of 8000r / min during the reaction. After the reaction was completed, the reaction solution was vacuum filtered, the solid product was washed three times, and then vacuum-dried at 50° C. for 12 hours, and then ground to obtain hydrophobically modified graphene oxide for future use.

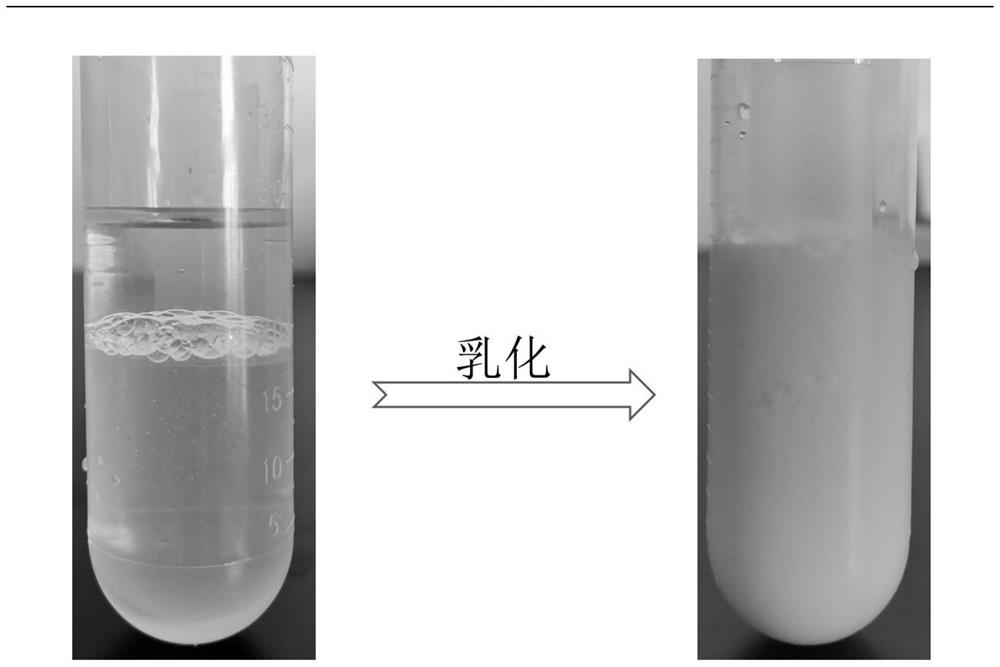

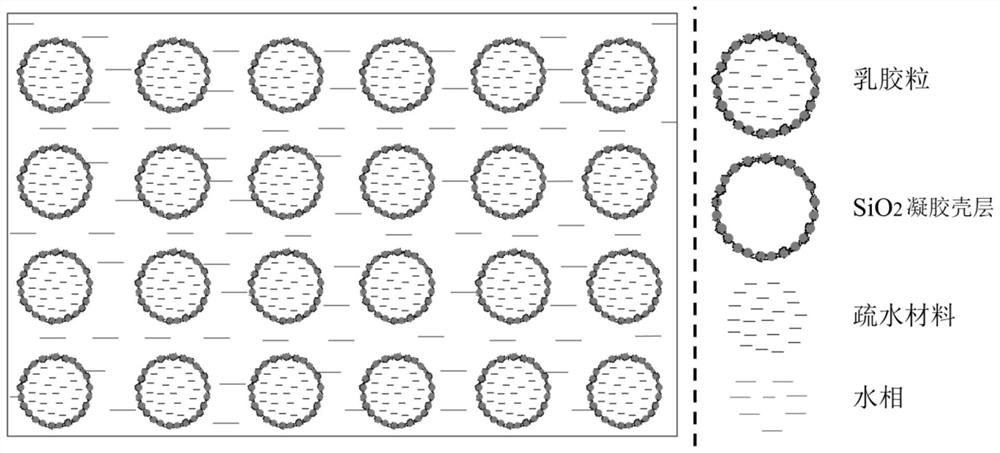

[0069] 2. Preparation of water-based microcapsule emulsion:

[0070] 2.1 Mix 23 parts by weight of deionized water and 1.6 parts by weight of polyvinyl al...

no. 2 example

[0078] A preparation of superhydrophobic microcapsule polymer cement-based anticorrosion coating, comprising the following methods:

[0079] 1. Preparation of hydrophobically modified graphene oxide:

[0080] 1.1 Add 4.5 parts by weight of graphene oxide into 160ml of absolute ethanol, and then ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion.

[0081] 1.2 Add 7.5 parts by weight of tridecafluorooctyltriethoxysilane to the graphene oxide dispersion, adjust the reaction temperature at 60°C for 24 hours, and vigorously stir at a rate of 6000r / min during the reaction. After the reaction was completed, the reaction solution was subjected to vacuum filtration, the solid product was washed three times, and then vacuum-dried at 60° C. for 8 hours, and then ground to obtain hydrophobically modified graphene oxide for future use.

[0082] 2. Preparation of water-based microcapsule emulsion:

[0083] 2.1 Mix 20 parts by weight of deionized water and 1.3 parts by ...

no. 3 example

[0091] A preparation of superhydrophobic microcapsule polymer cement-based anticorrosion coating, comprising the following methods:

[0092] 1. Preparation of hydrophobically modified graphene oxide:

[0093] 1.1 Add 3.5 parts by weight of graphene oxide into 150ml of absolute ethanol, and then ultrasonically disperse for 1 hour to obtain a graphene oxide dispersion.

[0094] 1.2 Add 4.5 parts by weight of tridecafluorooctyltrimethoxysilane to the graphene oxide dispersion, adjust the reaction temperature at 60°C for 20 hours, and vigorously stir at a rate of 5000 r / min during the reaction. After the reaction was completed, the reaction solution was vacuum filtered, the solid product was washed twice, and then vacuum-dried at 50° C. for 8.5 hours, and ground to obtain hydrophobically modified graphene oxide for future use.

[0095] 2. Preparation of water-based microcapsule emulsion:

[0096] 2.1 Mix 30 parts by weight of deionized water and 2 parts by weight of polyvinyl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com