A polydimethylsiloxane three-dimensional microfluidic channel surface hydrophobic structure forming process

A technology of polydimethylsiloxane and molding process, which is applied in the direction of laboratory utensils, laboratory containers, chemical instruments and methods, etc., and can solve the problems of low processing efficiency, high cost of femtosecond lasers, and superhydrophobic surface Roughness and other problems, to achieve the effect of high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

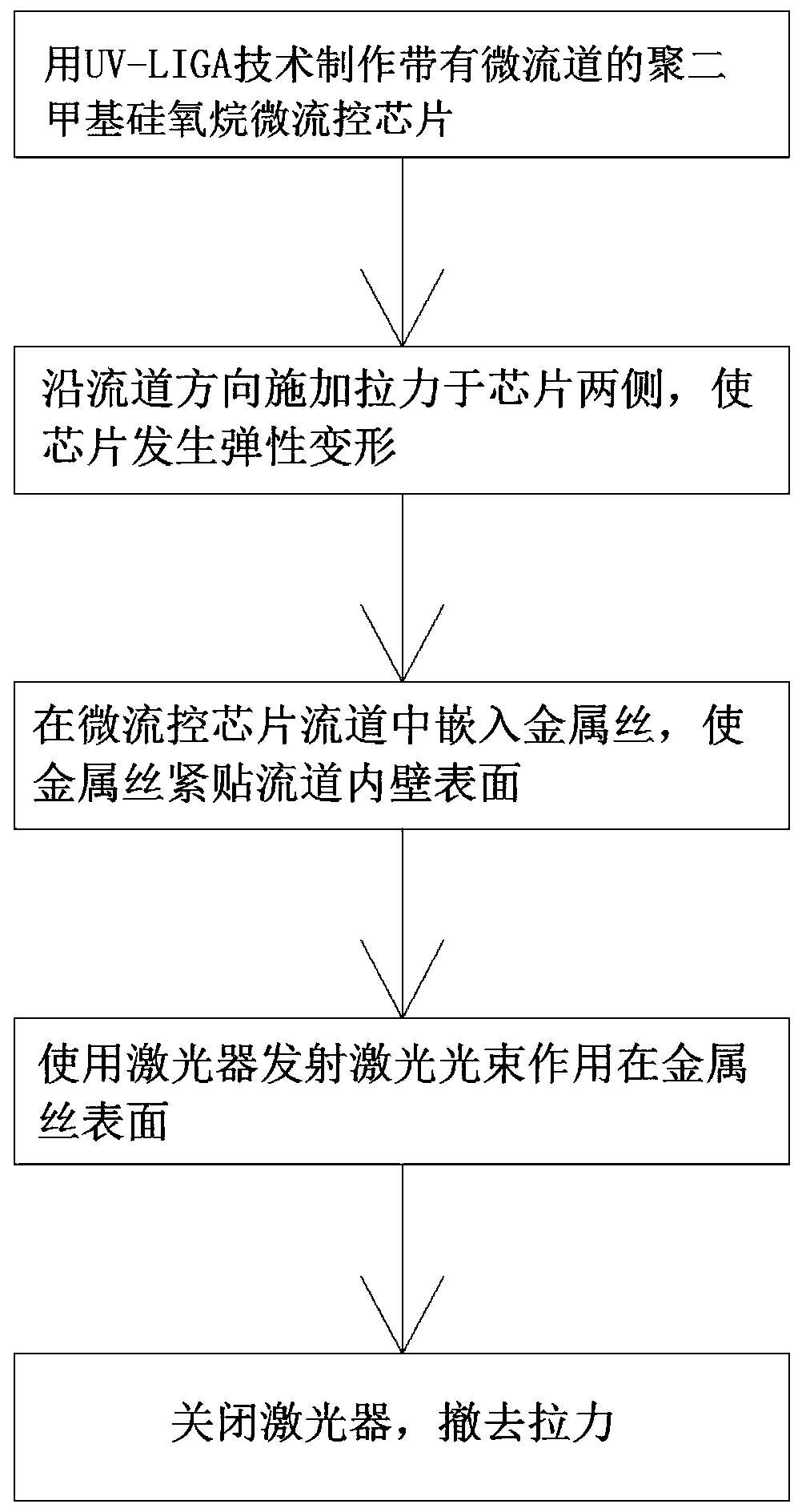

[0026] Embodiment: A polydimethylsiloxane three-dimensional microfluidic channel surface hydrophobic structure forming process.

[0027] A polydimethylsiloxane three-dimensional microfluidic channel surface hydrophobic structure forming process provided by the present invention comprises the following steps:

[0028] Step 1: Using UV-LIGA technology to fabricate a polydimethylsiloxane microfluidic chip with a microchannel, the width of the microchannel is 50 μm;

[0029] Step 2: Apply a pulling force of 0.5N on both sides of the chip along the direction of the flow channel to make the chip elastically deform;

[0030] Step 3: Embedding a metal wire with a diameter of 49 μm in the flow channel of the polydimethylsiloxane microfluidic chip in an elastically deformed state, so that the metal wire is close to the surface of the inner wall of the flow channel;

[0031] Step 4: Use a nanosecond fiber laser with a wavelength of 1064nm, a power of 10W, and a pulse frequency of 30kHz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com