Preparation of metal-coated sulfonated nitrogen-doped carbon nanotube magnetic solid acid catalyst and application of metal-coated sulfonated nitrogen-doped carbon nanotube magnetic solid acid catalyst in synthesis of diphenolic acid

A magnetic solid acid and carbon nanotube technology, which is applied in the direction of catalyst activation/preparation, organic compound preparation, physical/chemical process catalysts, etc., can solve the problems of energy consumption, time-consuming, cumbersome process, etc., and achieve simple separation and preparation The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

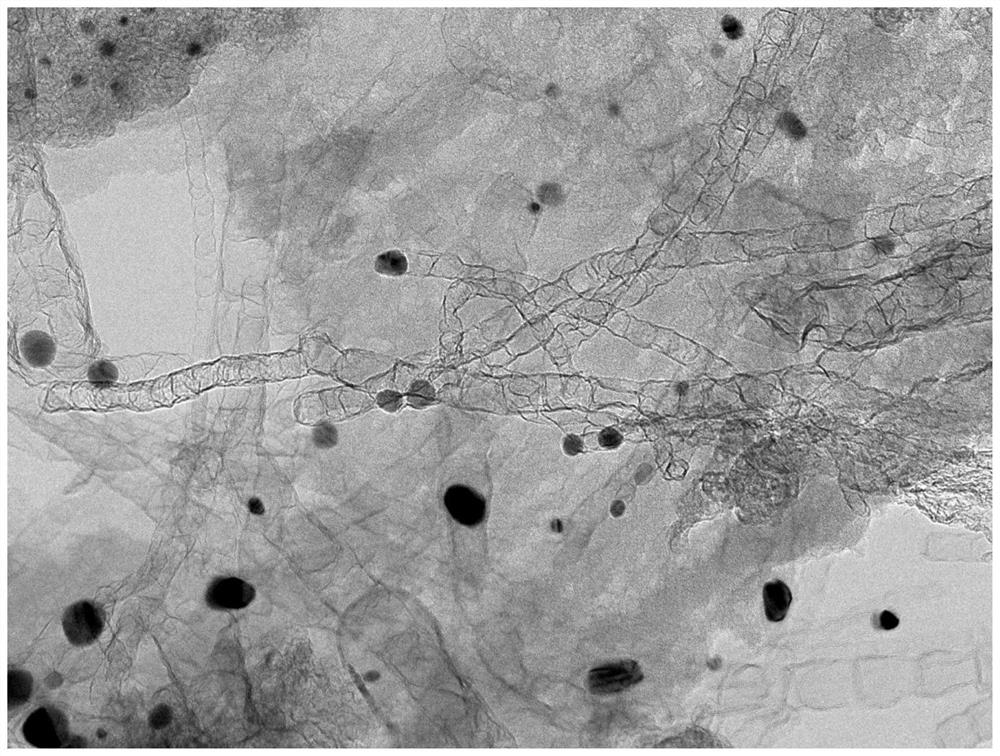

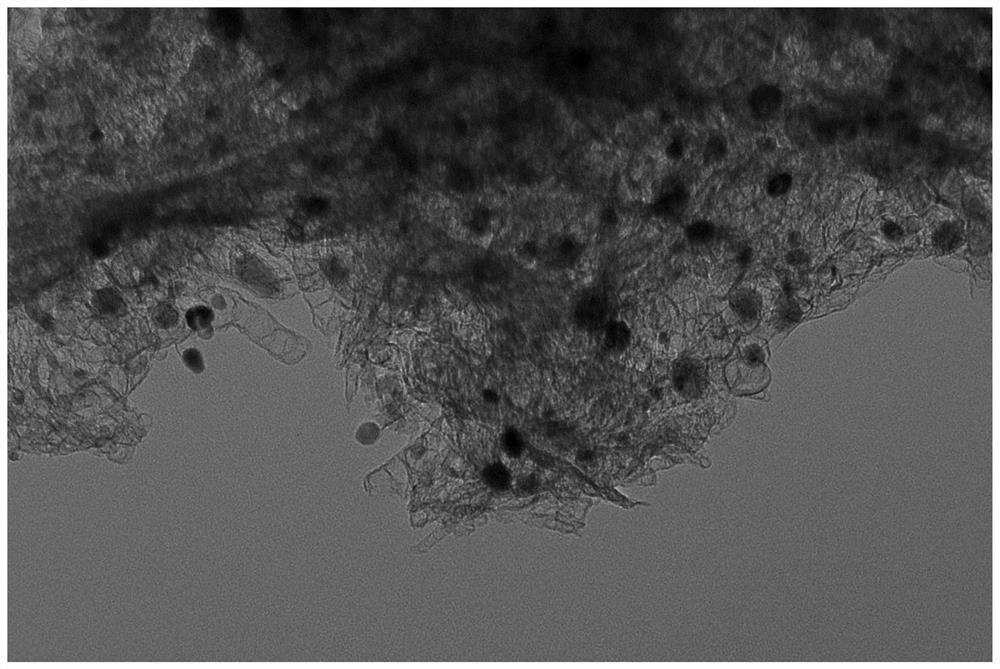

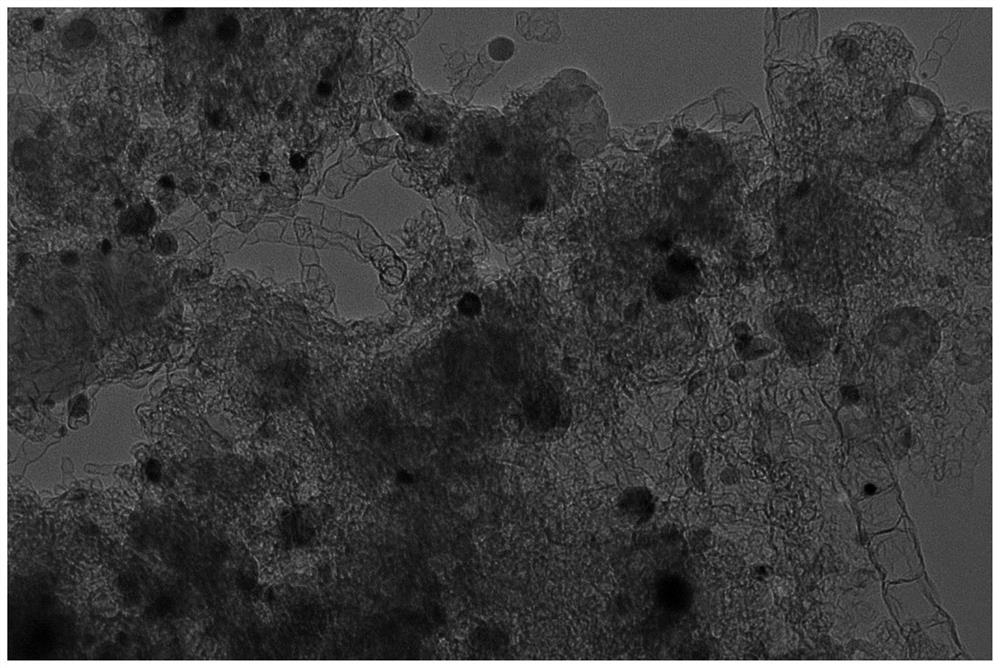

Image

Examples

Embodiment 1

[0037] The preparation method of the sulfonated nitrogen-doped carbon nanotube magnetic solid acid catalyst coated with metal cobalt in this embodiment comprises the following steps:

[0038] Step 1: Cobalt acetate, template agent and melamine were dissolved in water, and the resulting mixture was stirred at room temperature for 2 h, and further stirred at 80° C. for 0.5 h to obtain a suspension. Described cobalt acetate adopts [Co(CH 3 COO) 2 4H 2 O], the stencil agent is PEO-PPO-PEO, in which the mass ratio of cobalt acetate, stencil agent and melamine is 1:1.5:2.25; the mass ratio of cobalt acetate to water is 1:80.

[0039] Step 2: Remove the solvent in the suspension obtained in Step 1 by vacuum rotary evaporation, and calcinate the obtained powder at high temperature for 4-6 hours to obtain the calcined Co@NC. The calcined Co@NCs were further leached in an acid solution at 80 °C for 12 h, thoroughly washed with deionized water and dried to obtain Co@NCs. The calcinat...

Embodiment 2

[0042] The preparation method of the sulfonated nitrogen-doped carbon nanotube magnetic solid acid catalyst coated with metallic iron in this embodiment comprises the following steps:

[0043] Step 1: Ferric nitrate, template agent and melamine were dissolved in water, and the resulting mixture was stirred at room temperature for 2 h, and further stirred at 80° C. for 0.5 h to obtain a suspension. Described ferric acetate adopts [Fe(NO 3 ) 3 9H 2 O], the stencil agent is PEO-PPO-PEO, in which the mass ratio of ferric nitrate, stencil agent and melamine is 1:1.5:2.25; the mass ratio of ferric nitrate to water is 1:80.

[0044] Step 2: Remove the solvent in the suspension obtained in Step 1 by vacuum rotary evaporation, and calcinate the obtained powder at high temperature for 4-6 hours to obtain calcined Fe@NC. The calcined Fe@NC was further leached in an acid solution at 80°C for 12h, thoroughly washed with deionized water and dried to obtain Fe(@NC. The method of calcinati...

Embodiment 3

[0047] The preparation method of the sulfonated nitrogen-doped carbon nanotube magnetic solid acid catalyst coated with metal nickel in this embodiment comprises the following steps:

[0048] Step 1: Nickel nitrate, template agent and melamine were dissolved in water, and the resulting mixture was stirred at room temperature for 2 h, and further stirred at 80° C. for 0.5 h to obtain a suspension. Described nickel acetate adopts [Ni(NO 3 ) 2 ·6H 2 O], the stencil agent is PEO-PPO-PEO, wherein the mass ratio of nickel nitrate, stencil agent and melamine is 1:1.5:2.25; the mass ratio of nickel nitrate to water is 1:80.

[0049] Step 2: Remove the solvent in the suspension obtained in Step 1 by vacuum rotary evaporation, and calcinate the obtained powder at high temperature for 4-6 hours to obtain calcined Ni@NC. The calcined Ni@NC was further leached in an acid solution at 80 °C for 12 h, thoroughly washed with deionized water and dried to obtain Ni@NC. The calcination method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com