A kind of preparation method of egg yolk-eggshell structure composite material

A composite material and eggshell technology, which is applied in the field of nanomaterials, can solve the problems of reduced catalytic efficiency, easy agglomeration and deformation, and reduced catalytic activity, and achieve the effects of recycling and recycling, good magnetic separation effect, and high saturation magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

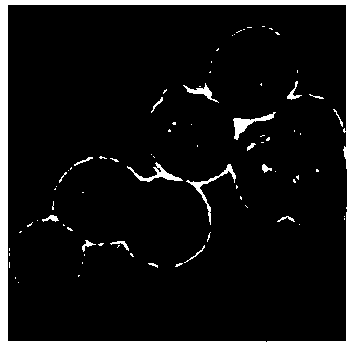

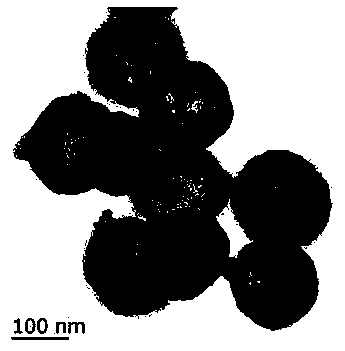

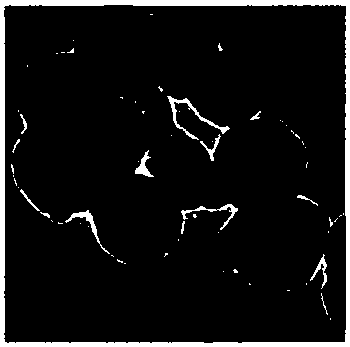

Image

Examples

Embodiment 1

[0041] (1) Hydrophobic Fe 3 o 4 Preparation of:

[0042] Weigh 0.9 g iron oleate, 0.156 g oleic acid, and 5 g 1-octadecene into a 50 mL three-neck flask, heat to 320 °C (at a heating rate of 18 °C / min), react for 1 h, and then quickly cool to room temperature After the reaction, the solid phase was washed three times with a mixed detergent of acetone and n-hexane to obtain about 0.2 g of ferric oxide particles coated with oleic acid on the surface.

[0043] Take 0.2 g of ferric oxide particles coated with oleic acid on the surface and disperse them in 72 mL of tetrahydrofuran to form Fe 3 o 4 dispersion in tetrahydrofuran.

[0044] (2) Hydrophobic Fe 3 o 4 Surface modification of:

[0045] Disperse 0.05 g DHCA into 6 mL THF, and add 6 mL Fe 3 o 4 The tetrahydrofuran dispersion was heated at 50°C for 3 h, cooled to room temperature and then added with 0.5 mL of NaOH aqueous solution with a concentration of 0.1 mol / L. After centrifugation, the solid was dispersed into 2...

Embodiment 2

[0057] (1) Hydrophobic Fe 3 o 4 preparation of

[0058] Same as the method of Example 1.

[0059] (2) Hydrophobic Fe 3 o 4 surface modification of

[0060] Same as the method of Example 1.

[0061] (3) Au@SiO2 2 Preparation and surface modification of core-shell materials

[0062] Same as the method of Example 1.

[0063] (4) Au@Fe 3 o 4 @m-SiO 2 Preparation of egg yolk-eggshell structure catalyst

[0064] The above prepared Au@SiO 2 Prepare a solution of 1 mg / mL, adjust the pH to 4 with NaOH solution and dilute hydrochloric acid, then add 18 mL of SiO 2 Dispersion, 9 mL of DHCA-Fe prepared by the method above 3 o 4 Water dispersion, stirred at room temperature for 4h.

[0065] After washing three times with water, disperse in 10 mL water, then add 300 mg CTAB, 6 mL ethanol, 48 μL TEOS and 120 μL ammonia water, stir and react for 3-4 h, then wash the solid phase with deionized water and absolute ethanol respectively After three times, add 4 mL of water and 84....

Embodiment 3

[0069] (1) Hydrophobic Fe 3 o 4 preparation of

[0070] Same as the method of Example 1.

[0071] (2) Hydrophobic Fe 3 o 4 surface modification of

[0072] Same as the method of Example 1.

[0073] (3) Au@SiO2 2 Preparation and surface modification of core-shell materials

[0074] Same as the method of Example 1.

[0075] (4) Au@Fe 3 o 4 @m-SiO 2 Preparation of egg yolk-eggshell structure catalyst

[0076] The above prepared Au@SiO 2 Prepare a solution of 1 mg / mL, adjust the pH to 4 with NaOH solution and dilute hydrochloric acid, then add 18 mL of SiO 2 Water dispersion, 9 mL of DHCA-Fe prepared by the above method 3 o 4 Water dispersion, stirred at room temperature for 4h.

[0077]After washing three times with water, disperse in 10 mL water, then add 300 mg CTAB, 6 mL ethanol, 27 μL TEOS and 120 μL ammonia water, stir and react for 3-4 h, then wash the solid phase for three times with deionized water and absolute ethanol respectively. Add 4 mL of water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com