A kind of hydrophobic modification method of paper

A technology of hydrophobic modification and hydrophobic modifier, applied in the field of medicine, can solve the problems of adverse effects of analysis, difficulty in removing emulsifier, high equipment cost, and achieve good biodegradability, low cost and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for hydrophobic modification of paper, specifically comprising the following steps:

[0033] (1) Take a piece of quantitative filter paper with a diameter of 12cm, and print polycaprolactone on the surface of the filter paper with a 3D printer. After printing, the surface of the filter paper is covered with polycaprolactone, such as figure 1 shown;

[0034] (2) Place the filter paper covered with polycaprolactone on the surface in an oven, control the temperature at 160° C., and heat for 1 min to melt the polycaprolactone and penetrate into the filter paper;

[0035] (3) The filter paper after heating and drying is taken out from the oven, placed at room temperature and cooled for 24h, to obtain a hydrophobically modified filter paper, such as figure 2 shown.

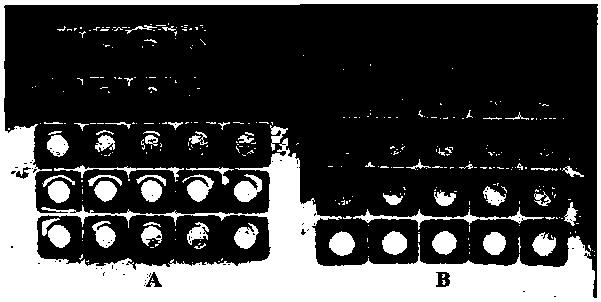

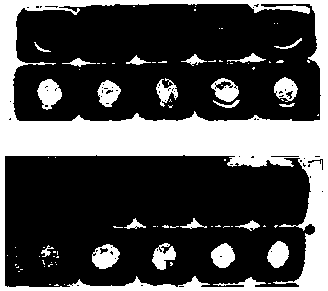

[0036] Add red ink dropwise on the modified filter paper, the result is as follows image 3 shown. Depend on image 3 It can be seen that after polycaprolactone is solidified, a hydrophobic region ...

Embodiment 2

[0038] A method for hydrophobic modification of paper, specifically comprising the following steps:

[0039] (1) Take a piece of white board paper with a diameter of 12 cm, and print polycaprolactone on the surface of the white board paper with a 3D printer. After printing, the surface of the filter paper is covered with polycaprolactone;

[0040] (2) Put the white board paper covered with polycaprolactone on the surface in an oven, control the temperature at 60°C, and heat for 24 hours, so that the polycaprolactone melts and penetrates into the white board paper;

[0041] (3) The heated and dried white board paper was taken out of the oven, and cooled at -20° C. for 1 min to obtain a hydrophobically modified white board paper.

[0042] Red ink was added dropwise on the modified white board paper, and it was found that polycaprolactone formed a hydrophobic area on the paper after solidification, and the hydrophobic modification was successful.

Embodiment 3

[0044] A method for hydrophobic modification of paper, specifically comprising the following steps:

[0045] (1) Take a piece of 70g printing paper, and print polycaprolactone onto the surface of the printing paper with a 3D printer. After printing, the surface of the printing paper is covered with polycaprolactone;

[0046] (2) Put the printing paper covered with polycaprolactone on the surface in an oven, control the temperature at 100° C., and heat for 6 hours to melt the polycaprolactone and penetrate into the printing paper;

[0047] (3) The heated and dried printing paper was taken out of the oven, and cooled at 59° C. for 240 min to obtain hydrophobically modified printing paper.

[0048] Red ink was added dropwise on the modified printing paper, and it was found that polycaprolactone formed a hydrophobic area on the paper after solidification, and the hydrophobic modification was successful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com