Forging process of planet carrier

A planet carrier and process technology, which is applied to the forging process field of the planet carrier, can solve the problems of large randomness of the shot blasting machine, incomplete treatment of the oxide skin of the planet carrier, and poor treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

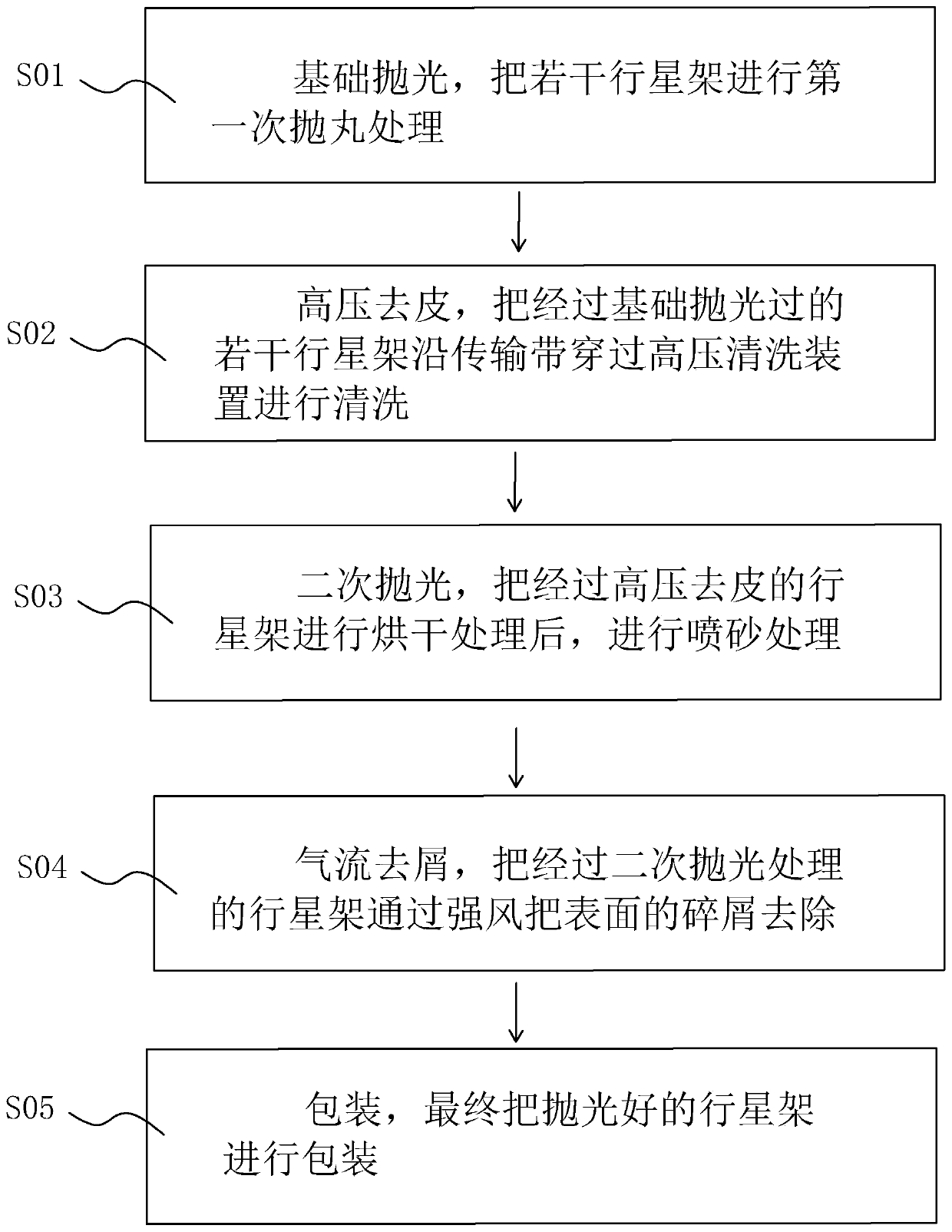

[0037] A kind of forging process of planet carrier, refer to figure 1 , including the following steps:

[0038] S01: Basic polishing, put several planetary frames through the shot blasting machine for the first shot blasting treatment to remove most of the oxide skin;

[0039] Shot blasting adopts a rotary table shot blasting machine; the shot blasting time is preferably set at 4 minutes; while ensuring the shot blasting effect, reduce the use of energy.

[0040] S02: High-pressure peeling, cleaning several planetary carriers that have been basically polished through the high-pressure cleaning device along the conveyor belt;

[0041] The transmission belt drives the planet carrier to move in a fixed direction. At this time, a number of high-pressure water guns are used to impact the planet carrier on the conveyor belt in a 360° circle. Removal of the scale attached to the surface of the planetary carrier but has fallen off under the shot blasting action of the shot blasting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com