Railway through ground wire as well as preparation device and preparation method thereof

A railway through-ground wire and channel technology, applied in circuits, cable/conductor manufacturing, conductors, etc., can solve problems such as the influence of cable core performance, energy consumption, and difficulty in controlling the uniformity of cable core thickness along the length direction, etc. Sheath metallographic structure is uniform, combined with reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

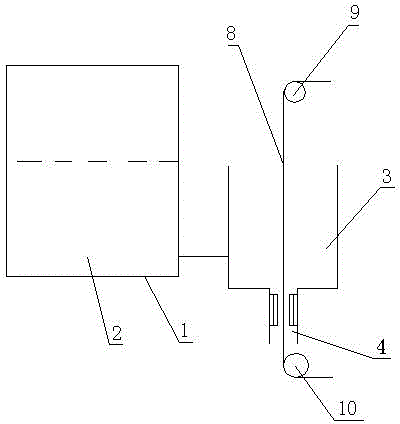

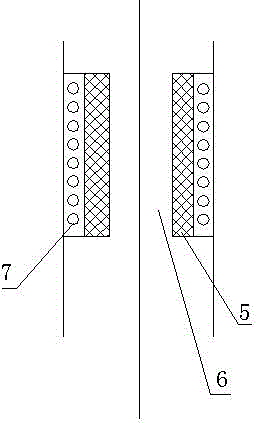

[0019] The railway penetration ground wire in this embodiment includes a cable core and a copper alloy sheath coated on the outer layer of the cable core. The composition of the sheath includes copper, zinc, aluminum, arsenic and a rare earth element. The rare earth element can be lanthanum (La ) and neodymium (Nd), the thickness of the copper alloy sheath is 0.9mm.

[0020] The method for producing railway through-ground wires using the above-mentioned preparation device for railway through-ground wires, specifically, melts copper alloy melt in a holding furnace, submerges the copper alloy melt into the crystallization furnace and infiltrates the down-leading channel, and installs the copper alloy melt in the cable The cable core on the core unwinding wheel passes through the down-leading channel from top to bottom. The diameter of the down-leading channel matches the thickness of the copper alloy sheath to be prepared. When the core is drawn down, the circulating cooling wat...

Embodiment 2

[0022]The railway penetration ground wire in this embodiment includes a cable core and a copper alloy sheath covering the outer layer of the cable core. The composition of the sheath includes copper, zinc, aluminum, arsenic and rare earth elements. The rare earth elements can be niobium and cesium , the thickness of the copper alloy sheath is 1mm.

[0023] The method for producing railway through-ground wires using the above-mentioned preparation device for railway through-ground wires, specifically, melts copper alloy melt in a holding furnace, submerges the copper alloy melt into the crystallization furnace and infiltrates the down-leading channel, and installs the copper alloy melt in the cable The cable core on the core unwinding wheel passes through the down-leading channel from top to bottom, the diameter of the down-leading channel matches the thickness of the copper alloy sheath to be produced, and the down-leading speed of the cable core is 6000mm / min; When the cable ...

Embodiment 3

[0025] The railway penetration ground wire in this embodiment includes a cable core and a copper alloy sheath coated on the outer layer of the cable core. The composition of the sheath includes copper, zinc, aluminum, arsenic and a rare earth element. The rare earth element can be neodymium (Nd ), the thickness of the copper alloy sheath is 6mm.

[0026] The method for producing railway through-ground wires using the above-mentioned preparation device for railway through-ground wires, specifically, melts copper alloy melt in a holding furnace, submerges the copper alloy melt into the crystallization furnace and infiltrates the down-leading channel, and installs the copper alloy melt in the cable The cable core on the core unwinding wheel passes through the down-leading channel from top to bottom. The diameter of the down-leading channel matches the thickness of the copper alloy sheath to be prepared. When the core is drawn down, the circulating cooling water is turned on, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com