Dielectric isolation material taking thermosetting resin as matrix and preparation method of material

A dielectric isolation and thermosetting technology, which is applied in the field of electrical insulation composite materials, can solve the problems of melting, anti-static dielectric isolation performance deterioration, etc., and achieve good mechanical properties and good electrical insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

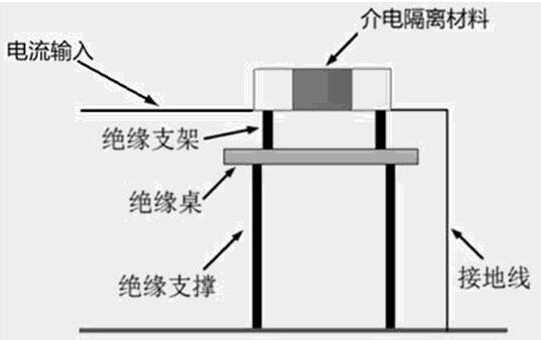

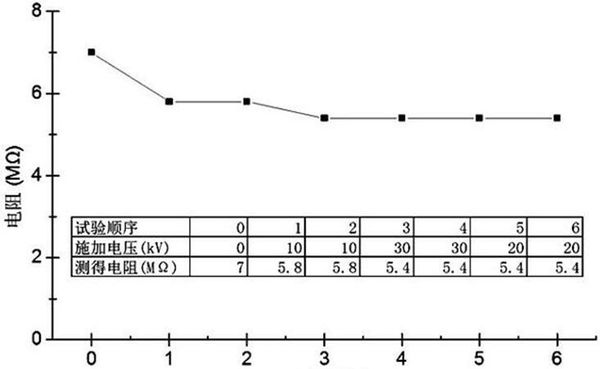

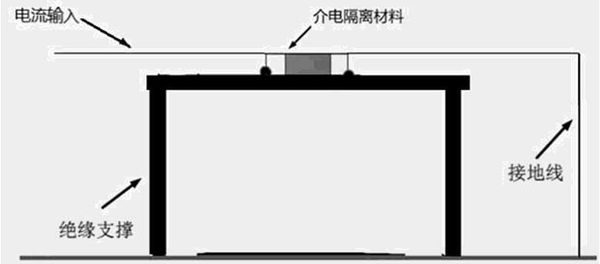

Image

Examples

Embodiment 1

[0039] A dielectric isolation material based on a thermosetting resin, which is a composite material made of the following raw materials by mass: 60% to 80% of E glass fiber, conductive carbon black (CB) and F-48 resin (phenolic aldehyde Type epoxy resin, including curing agent), the sum is 40% to 20%, the ratio of CB to F-48 resin is 0.5:99.5, and the average particle size of CB is 10nm;

[0040] The preparation method of this material comprises the following steps:

[0041] A. Disperse CB evenly in F-48 resin, and then vacuum defoam the dispersed glue until there are no bubbles in the glue;

[0042] B. Immerse the E glass fiber in the glue solution of step A until the fiber is completely soaked, and the time for complete soaking is 24 hours, then remove the excess glue solution in the fiber, so that the average amount of glue dipped in the E glass fiber is 40%, 30% respectively %, 20%, and then undergo vacuum defoaming treatment until there are no air bubbles in the fibers...

Embodiment 2

[0047] A dielectric isolation material based on a thermosetting resin, which is a composite material made of the following raw materials by mass: 65% to 80% of basalt fiber braid, CB and E-44 resin (bisphenol A ring Oxygen resin, containing curing agent) is 35% to 20%, the ratio of CB to E-44 resin is 7:93, and the average particle size of CB is 10nm;

[0048] The preparation method of this material comprises the following steps:

[0049] A. Disperse CB evenly in E-44 resin, and then perform centrifugal degassing treatment on the dispersed glue until there are no bubbles in the glue;

[0050] B. Immerse the basalt fiber braid in the glue solution of step A for 24 hours until the fiber is completely soaked, then remove the excess glue solution in the fiber braid, so that the average amount of glue dipped in the fiber braid is 35%, 25%, 20% , and then undergo vacuum defoaming treatment until there are no air bubbles in the fiber braid impregnated with glue;

[0051] C. Curin...

Embodiment 3

[0055] A dielectric isolation material based on a thermosetting resin, which is a composite material made of the following raw materials by mass: E glass fiber (single filament diameter 9.5-10.5μm) 60%-80%, ultra-fine graphite powder The sum of the graphite powder and the silicone resin is 40% to 20%, the ratio of the ultrafine graphite powder to the silicone resin is 5:95, and the average particle size of the ultrafine graphite powder is 20nm;

[0056] The preparation method of this material comprises the following steps:

[0057] A. Evenly disperse the ultra-fine graphite powder in the silicone resin, and then vacuum defoam the dispersed glue until there are no bubbles in the glue;

[0058] B. Immerse the E glass fiber in the glue solution of step A for 20 hours until the fiber is completely soaked, then remove the excess glue solution in the fiber, so that the average amount of glue dipped in the E glass fiber is 40%, 30%, 20%, and then Vacuum defoaming treatment until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com