A kind of ultra-fine-grain sialon-based ceramic material with high temperature plasticity and preparation method thereof

A technology of ceramic materials and high temperature plasticity, applied in the field of ceramic materials, can solve the problems of difficult to process ceramic parts, poor high temperature plasticity, high processing cost, and achieve the effect of accelerating the densification process, promoting liquid phase sintering, and reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a Sialon-based ceramic material with high temperature plasticity, comprising the following steps:

[0028] S1, the amorphous nano-Si 3 N 4 Powder, nano-AlN powder and composite sintering aid are mixed to obtain mixed powder;

[0029] S2, performing spark plasma sintering on the mixed powder obtained in step S1 to obtain an ultrafine-grained Sialon-based ceramic material;

[0030] The composite sintering aid includes GH4169 superalloy powder, Y 2 o 3 Powder and Al 2 o 3 pink.

[0031] Unless otherwise specified, the raw materials used in the present invention are all commercially available.

[0032] In the present invention, amorphous nano-Si 3 N 4 Powder, nanometer AlN powder and composite sintering aid are mixed to obtain mixed powder. In the present invention, the composite sintering aid includes GH4169 superalloy powder, Y 2 o 3 Powder and Al 2 o 3 pink. In the present invention, in the mixed powder, amorph...

Embodiment 1

[0043] Amorphous nano-Si with a particle size of 20-25nm 3 N 4 powder, nano-AlN powder with a particle size of 38-42nm, and Y powder with a particle size of 18-22nm 2 o 3 Powder, Al with a particle size of 18-22nm 2 o 3 Powder and GH4169 superalloy powder with a particle size of 45-85 μm were mixed according to the mass ratio of 47:3:4:6:40, ball milled at 200 rpm for 2 hours, the ball milling medium was absolute ethanol, and the ball-to-material ratio was 1:6. After drying, a mixed ceramic powder is obtained.

[0044] Under the protection of argon atmosphere, the mixed ceramic powder was sintered by spark plasma sintering process. The sintering temperature was 1250°C, the heating rate was 50°C / min, the sintering holding time was 45min, and the sintering pressure was 30MPa. Sialon based ceramic material.

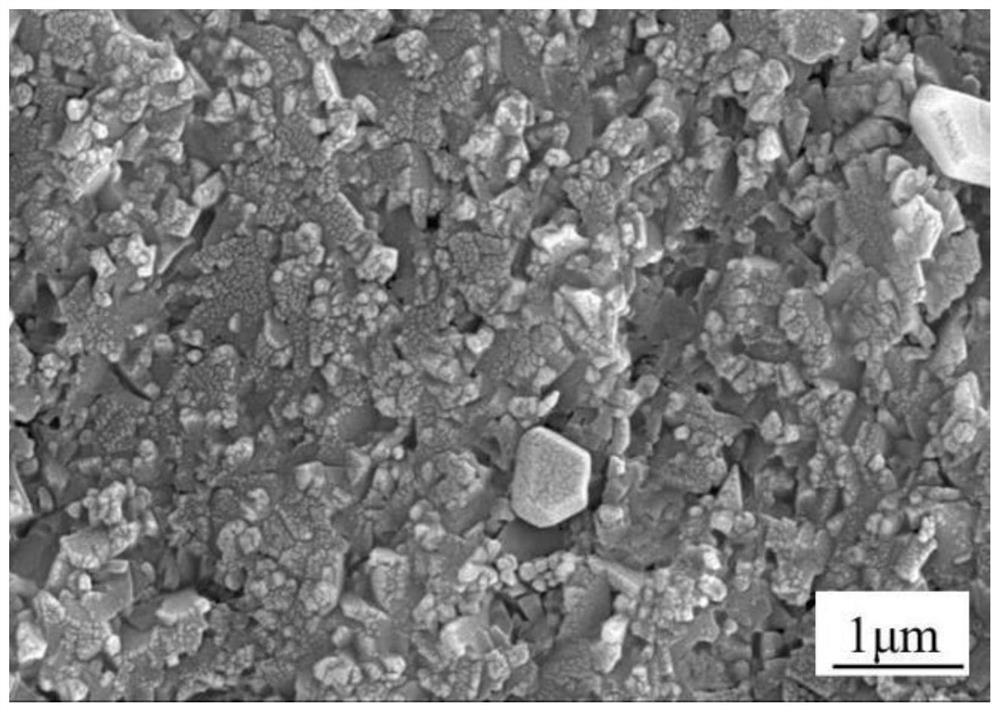

[0045] The density of the obtained Sialon-based ceramic material can reach 97%, and the main phase composition is O'-Sialon phase, and its microstructure and morpholog...

Embodiment 2

[0048] Amorphous nano-Si with a particle size of 20-25nm 3 N 4 powder, nano-AlN powder with a particle size of 38-42nm, and Y powder with a particle size of 18-22nm 2 o 3 Powder, Al with a particle size of 18-22nm 2 o 3 Powder and GH4169 superalloy powder with a particle size of 45-85 μm were mixed according to the mass ratio of 47:3:4:6:40, ball milled at 200 rpm for 2 hours, the ball milling medium was absolute ethanol, and the ball-to-material ratio was 1:6. After drying, a mixed ceramic powder is obtained.

[0049] Under the protection of argon atmosphere, the mixed ceramic powder was sintered by spark plasma sintering process. The sintering temperature was 1250°C, the heating rate was 50°C / min, the sintering holding time was 60min, and the sintering pressure was 30MPa. Sialon based ceramic material.

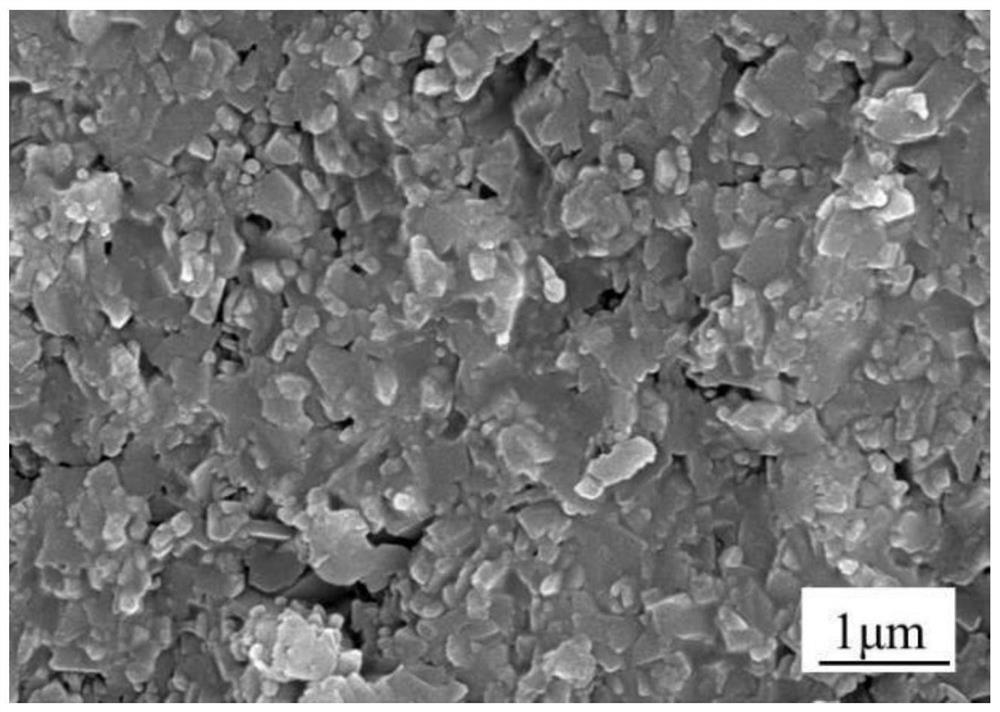

[0050] The density of the obtained Sialon-based ceramic material can reach 98.5%, and the main phase composition is O'-Sialon phase, and its microstructure and morphol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com