Low-noise milk-preparation method of soybean milk machine

A low-noise, soymilk machine technology, applied in beverage preparation devices, dough forming and cutting equipment, household appliances, etc., can solve problems such as high noise and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0029] A low-noise pulping method for a soybean milk machine, which provides a motor, a crushing tool, a heating device, and a cup body. The control unit is electrically connected to the motor and the heating device, and at least includes the following stages:

[0030] (1) Crushing stage: the motor drives the crushing cutter to rotate and crush water and materials to slurry, and enter the next stage;

[0031] (2) Boiling stage: the heating device heats the slurry until it is cooked.

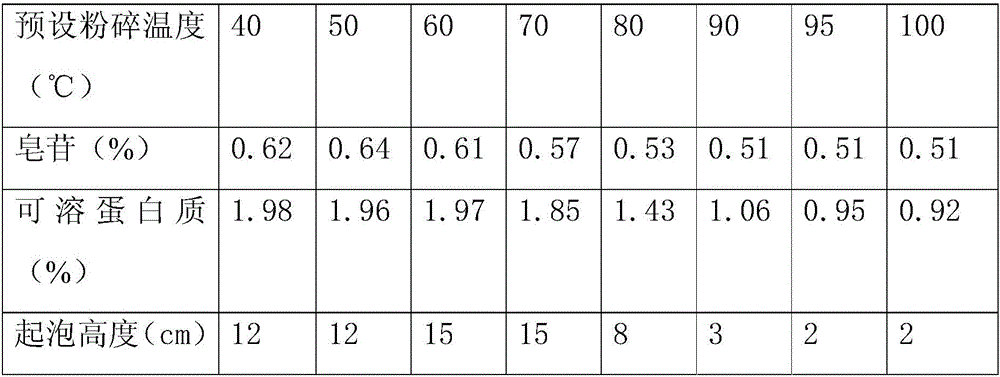

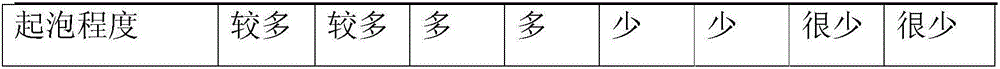

[0032] The temperature of the liquid at the beginning of the crushing stage is greater than or equal to the preset crushing temperature, and the preset crushing temperature is greater than or equal to 85°C. Before the crushing stage starts, a heating pretreatment stage is also included, and the total duration of the heating pretreatment stage is for 400 to 800 seconds.

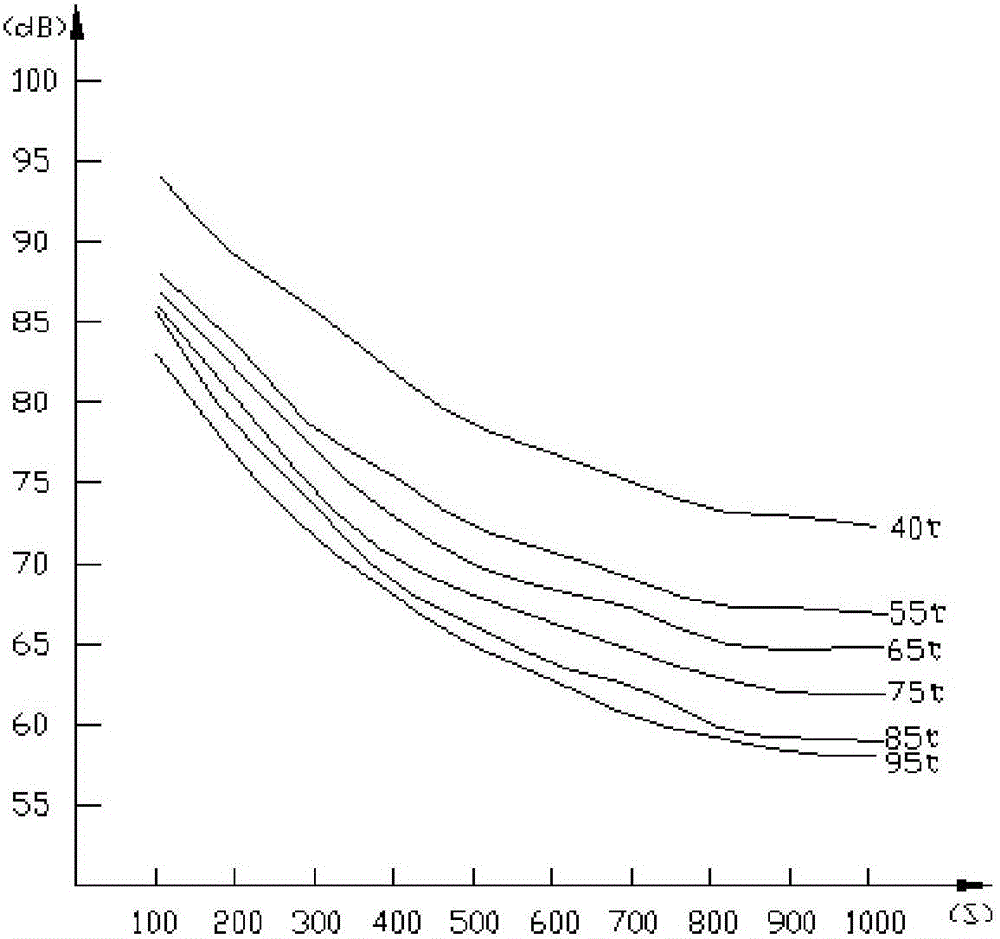

[0033] Since the noise in the pulping process is mainly due to the peak noise of high-speed concentrated crushing after the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com