Device and method for supercritical carbon dioxide high-pressure jet flow plug removal seepage enhancement

A carbon dioxide, high-pressure jet technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of complex equipment, unpredictable pressure, high fracture initiation pressure in hard formations, and achieve high energy utilization, increase The effect of large porosity and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

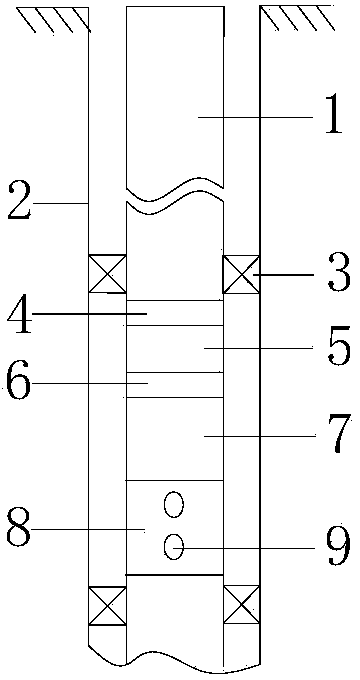

[0015] The main structure of the supercritical carbon dioxide high-pressure jet flow plugging removal and permeability enhancement device involved in this embodiment includes oil pipe 1, casing 2, packer 3, detonator 4, propellant 5, piston 6, cylinder liner 7, and diversion joint 8 and nozzle 9; the casing 2 is sleeved on the outside of the tubing 1 to form an upper and lower passage, and the upper and lower passages between the casing 2 and the tubing 1 are evenly equipped with packers 3, and the number of packers 3 is set according to actual needs The detonator 4 is arranged in the oil pipe 1 and is connected with the oil pipe 1. The detonator 4 adopts a commercially available wireless or wired detonator; The middle is filled with propellant 5; the lower end of the piston 6 is made with a cylinder liner 7 filled with supercritical carbon dioxide, and the piston 6 moves downward in the cylinder liner 7; The supercritical carbon dioxide in the medium is divided and directed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com