Method for increasing coal-bed gas recovery ratio by using coal-bed indigenous microbes

A technology of endogenous microorganisms and coalbed methane, applied in the direction of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of high carbonization degree of high-rank coal seams, inability to improve the recovery rate of coalbed methane, and difficult microbial degradation, etc. problems, to achieve the effect of promoting drainage, reducing application costs, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment simulates the microbial gas recovery process of the present invention in a laboratory. The experimental process is as follows: 160g of coal seam produced water is used to prepare nutrient solution, and the amount of nutrients added is: 0.4g of glucose, 0.8g of molasses, 0.16g of ammonium chloride, 0.08g of yeast extract, 0.16g of dipotassium hydrogen phosphate, and 0.16g of dipotassium phosphate. Sodium hydrogen 0.016g, magnesium chloride 0.016g, sodium acetate 0.24g, sodium nitrate 0.16g; put the prepared nutrient solution in a 250ml anaerobic bottle, and add 150g coal to the anaerobic bottle, seal the sample for culture, and collect the gas .

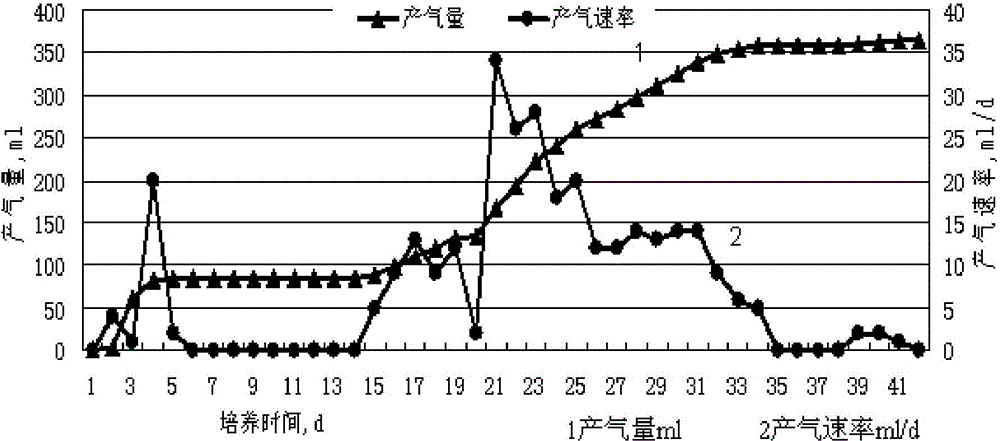

[0069] Gas production curve see figure 1 The sample reaction time is 42 days, the total amount of gas produced is 340ml, the gas production rate is 2.125ml gas per milliliter of nutrient solution, and the gas production per gram of coal is 2.267ml. The amount of gas produced reached the maximum on the 32nd day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com