Synergistic-denitration type liquid boiler clinker removal agent and preparation method and application thereof

A decoking agent and boiler technology, which is used in fuel additives, petroleum industry, solid fuels, etc., can solve the problems of increasing the difficulty of denitrification, the cost of out-of-stock, increasing pollutant emissions, and increasing emissions, reducing initial emissions, The effect of reducing bond strength and promoting combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

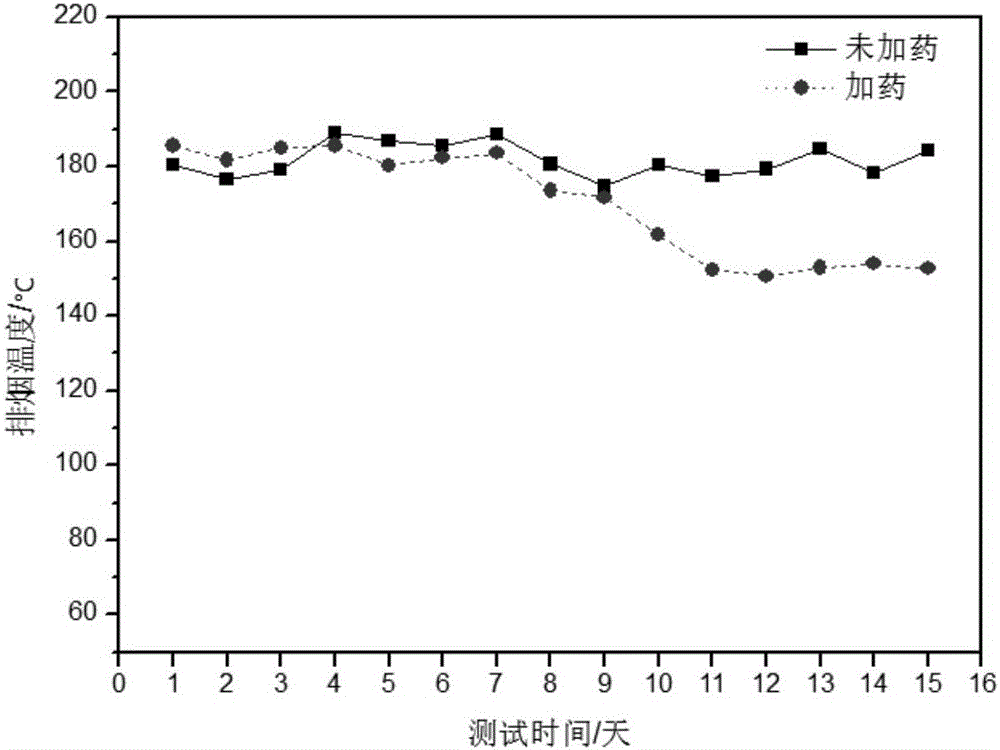

Examples

Embodiment 1

[0032] To prepare 100Kg of decoking agent, the components and formula are:

[0033] Magnesium acetate: 18Kg; copper nitrate: 2Kg; nickel nitrate: 2Kg; ammonium nitrate: 5Kg; boric acid: 3Kg; cerium nitrate: 0.5Kg; water: 69.5Kg.

[0034]The preparation process is as follows: Equipped with a mixing bucket, with a vertical liquid mixer on the top of the bucket; adding water in the mixing bucket according to the preparation ratio, then adding boric acid first, stirring with a mixer to completely dissolve the boric acid, and then adding cerium nitrate, copper nitrate, nitric acid Nickel and ammonium nitrate are stirred until each component is completely dissolved, and finally magnesium acetate is added and stirred until completely dissolved to obtain a liquid boiler decoking agent. Pour the decoking agent into the pressure spray can, connect the compressed air to the pressure spray can, then connect the spray gun to the pressure spray can, insert the spray gun into the furnace vie...

Embodiment 2

[0039] To prepare 100Kg of decoking agent, the components and formula are:

[0040] Magnesium acetate: 10Kg; copper nitrate: 3Kg; nickel nitrate: 2Kg; ammonium nitrate: 8Kg; boric acid: 8Kg; cerium nitrate: 1Kg; water: 68Kg.

[0041] Its preparation method, application method, addition amount and addition times are the same as those in Example 1.

Embodiment 3

[0043] To prepare 100Kg of decoking agent, the components and formula are:

[0044] Magnesium acetate: 8Kg; copper nitrate: 5Kg; nickel nitrate: 3Kg; ammonium nitrate: 8Kg; boric acid: 5Kg; cerium nitrate: 1.5Kg; water: 69.5Kg.

[0045] Its preparation method, application method, addition amount and addition times are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com