Multi-grain simultaneous cooking type grain steaming method

A technology for grain and steamed grain, applied in the field of winemaking, can solve the problems of long cooling time of grain, incomplete starch gelatinization and loss, and achieve the effects of improving the purity of wine body, increasing porosity and reducing bran flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

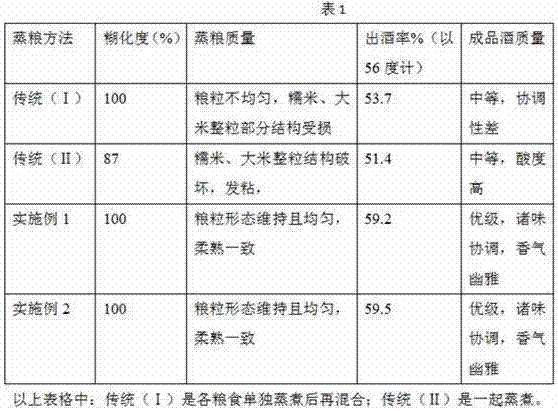

Image

Examples

Embodiment 1

[0019] This embodiment includes the following steps:

[0020] (1) Multi-grain raw materials are composed of sorghum, rice, glutinous rice, wheat and corn, and its composition ratio is 40% sorghum, 20% rice, 20% glutinous rice, 15% wheat, and 5% corn;

[0021] (2) Sorghum treatment: wash sorghum at room temperature, remove suspended solids and slag and sand, soak grain at 55°C for 18 hours, add water first, then add grain, the water surface is 10 cm higher than the sorghum; after soaking grain, drain the water and let it stand Cook for 1 hour at normal pressure for 30 minutes, then simmer in water at 90°C for 0.5 hours, until the surface of the water covers the sorghum by 5 cm until the grain opening rate of the sorghum reaches 85%, stir occasionally, drain the water again, and let it stand for 1 hour for later use ;

[0022] (3) Corn processing: crush the corn to 2 mm sized particles, soak the grain at 55°C for 18 hours, and set aside;

[0023] (4) Treatment of rice and glut...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] (1) Multi-grain raw materials are composed of sorghum, rice, glutinous rice, wheat and corn. The composition ratio is 40% sorghum, 25% rice, 15% glutinous rice, 12% wheat and 8% corn;

[0029] (2) Sorghum treatment: wash sorghum grains at room temperature, remove suspended solids and slag, and soak grains at 70°C for 4 hours, add water first, then add grains, and the water surface covers the sorghum by 10 cm; after soaking grains, drain the water and let it stand Cook for 1.5 hours at normal pressure for 40 minutes, then simmer in water at 88°C for 1 hour until the water surface covers the sorghum by 5 cm until the grain opening rate of the sorghum reaches 80%, stir occasionally, drain the water again, and let it stand for 1 hour for later use ;

[0030] (3) Corn processing: crush the corn to 1.5 mm in size, soak the grain at 50°C for 16 hours, and set aside;

[0031] (4) Treatment of rice and glutinous rice: soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com