Environment-friendly efficient train cleaning agent and preparation method thereof

The technology of cleaning agent and cleaning aid is applied in the field of environmentally friendly and high-efficiency cleaning agent for trains and its preparation. , the effect of improving solubility and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

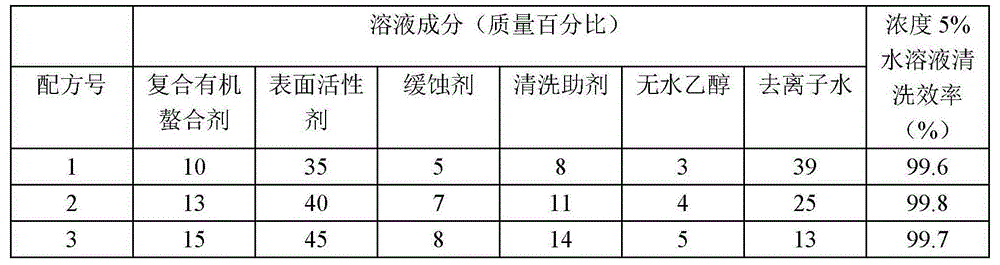

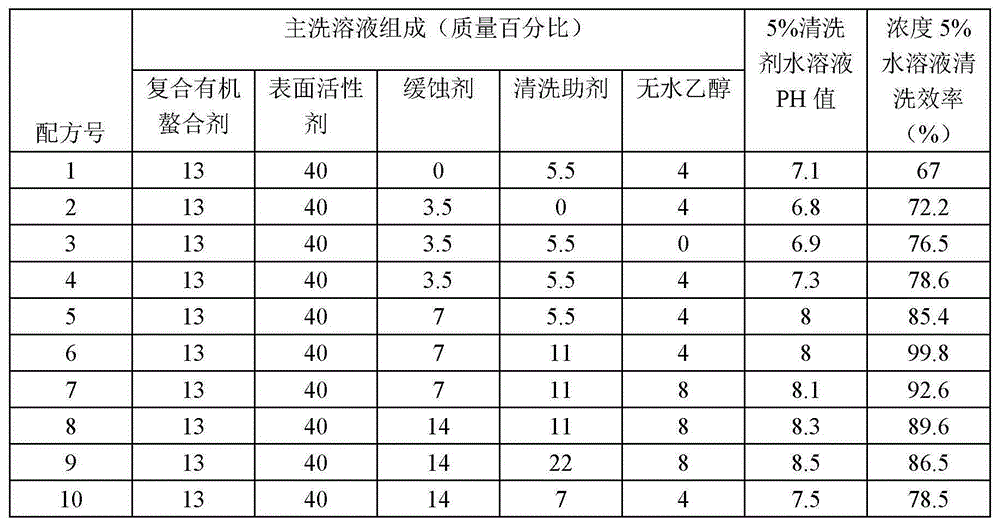

[0020] Each component is selected according to the following mass percentages: 10-15% of compound organic chelating agent, 35-45% of surfactant, 5-8% of corrosion inhibitor, 8-14% of cleaning aid, 3-5% of absolute ethanol, The balance is deionized water, and the corrosion inhibitor is composed of urotropine, sodium metasilicate pentahydrate and benzotriazole according to the mass-number ratio of 13-17:28-32:53-57; In the agitator, first dissolve the benzotriazole with absolute ethanol to obtain the absolute ethanol and benzotriazole solution for use, then add the compound organic chelating agent in deionized water at 35-40°C, and stir until After fully dissolved, add cleaning aid, absolute ethanol and benzotriazole solution, urotropine and sodium metasilicate pentahydrate in sequence, stir until completely dissolved, then add surfactant, continue stirring until the solution is completely dissolved into a uniform Transparent liquid, finally sealed and packaged, waterproof and m...

Embodiment 2

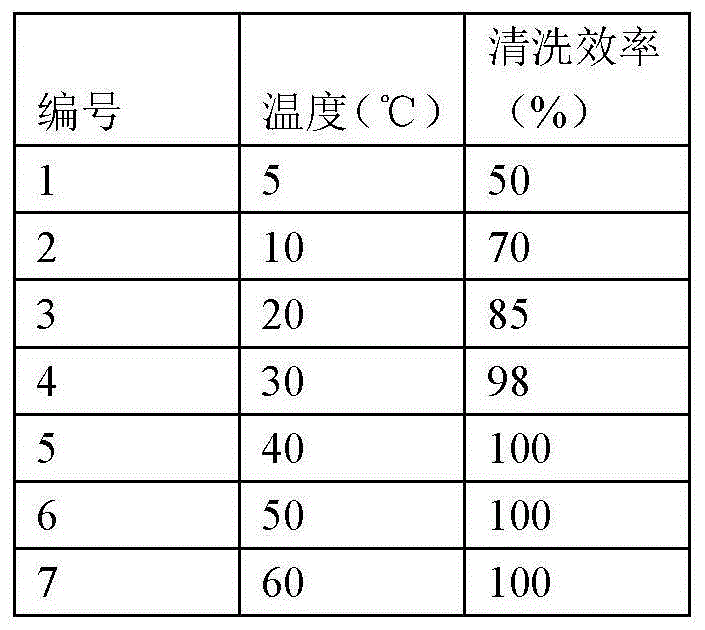

[0035] According to the preparation method of Example 1, take the train environmental protection high-efficiency cleaning agent aqueous solution prepared by the formula number 6, dilute it to a concentration of 5%, clean the test piece with a small ultrasonic cleaning machine for 5 minutes, and test the effect of different temperatures on the cleaning efficiency. Influence, the results are shown in Table 2:

[0036]

[0037] Table 3 Comparison Table of Cleaning Efficiency Effects of Different Temperatures

[0038] The results show that the cleaning efficiency is better when the cleaning temperature is above 20°C, and the cleaning efficiency does not change above 30°C, so it is generally better to choose a temperature of 35°C for cleaning.

Embodiment 3

[0040] According to the preparation method of Example 1, take the train environmental protection and high-efficiency cleaning agent aqueous solution prepared by the formula number 6, dilute to different concentrations at 35 ° C, clean the test piece with a small ultrasonic cleaner for 5 minutes, and test the effect of different concentrations on cleaning efficiency , the results are shown in Table 3:

[0041]

[0042] Table 4 Comparison Table of Cleaning Efficiency Effects of Different Concentrations

[0043] The results show that the cleaning efficiency is better when it is diluted to a concentration of 5% to 6%. Considering the cleaning cost, 5% is the best dilution concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com