Patents

Literature

55results about How to "Low iodine value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel wax for reducing mar and abrasion in inks and coatings

InactiveUS20050131103A1Produce economicallyIncrease their performance propertyCarboxylic acid esters preparationPretreated surfacesIodine valueWax

Owner:HRD CORP

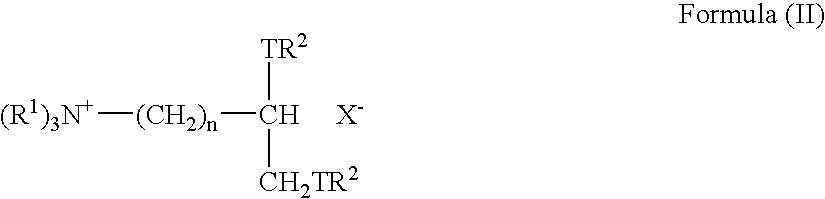

Fabric treatment composition

InactiveUS20030199416A1Promote softeningReduce stainsCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

A heat activated fabric treatment composition comprises from 3 to 75 wt % of one or more fabric treatment active ingredients, from 10 to 50 wt % of water, from 5 to 40 wt % of an oil and optionally from 2 to 30 wt % of a nonionic surfactant. The composition is provided in a dispensing device which, in use, is attached to the internal panel of a tumble dryer.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

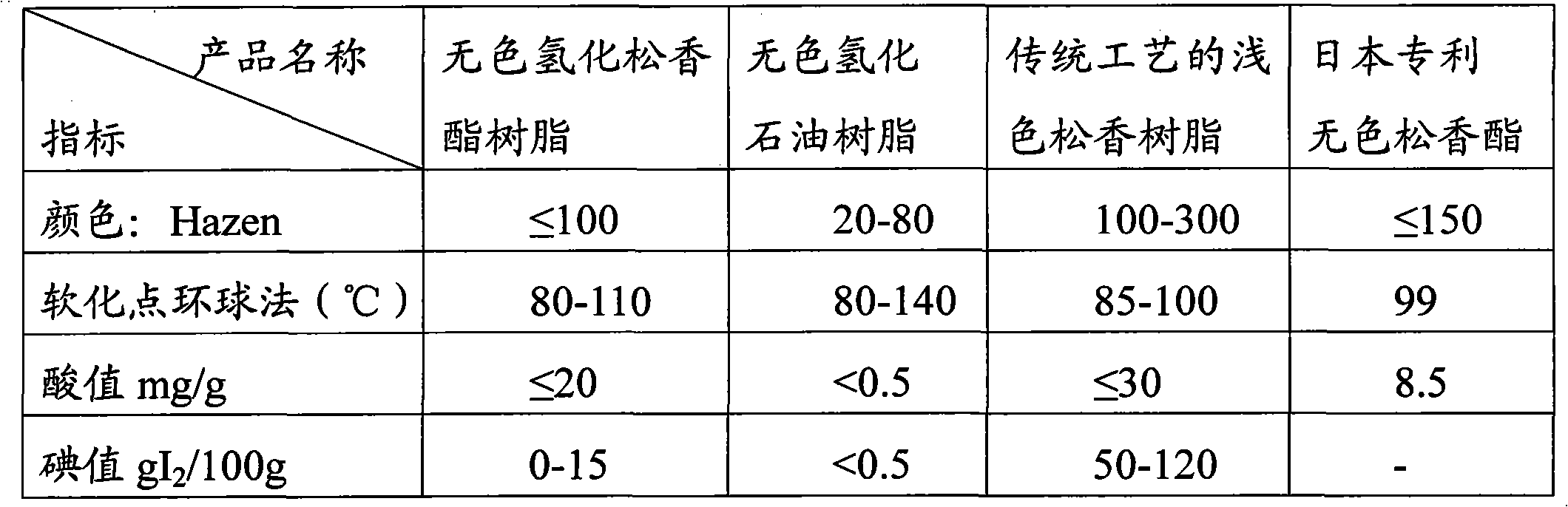

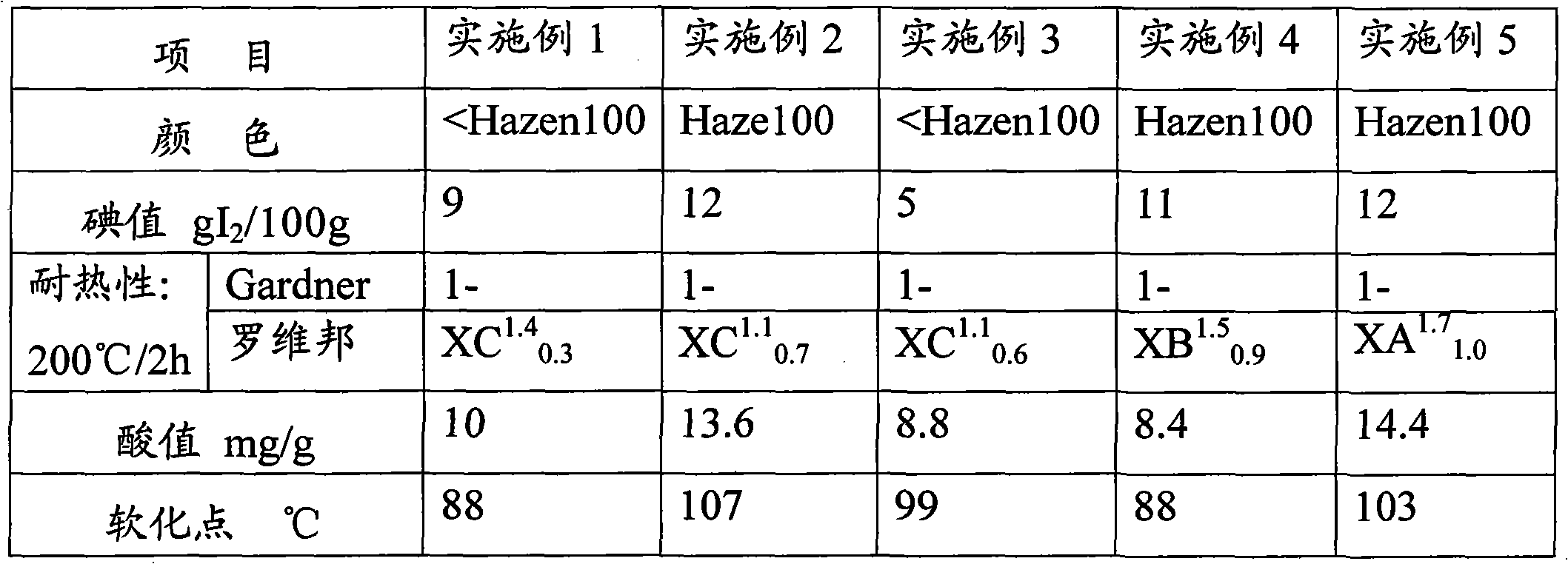

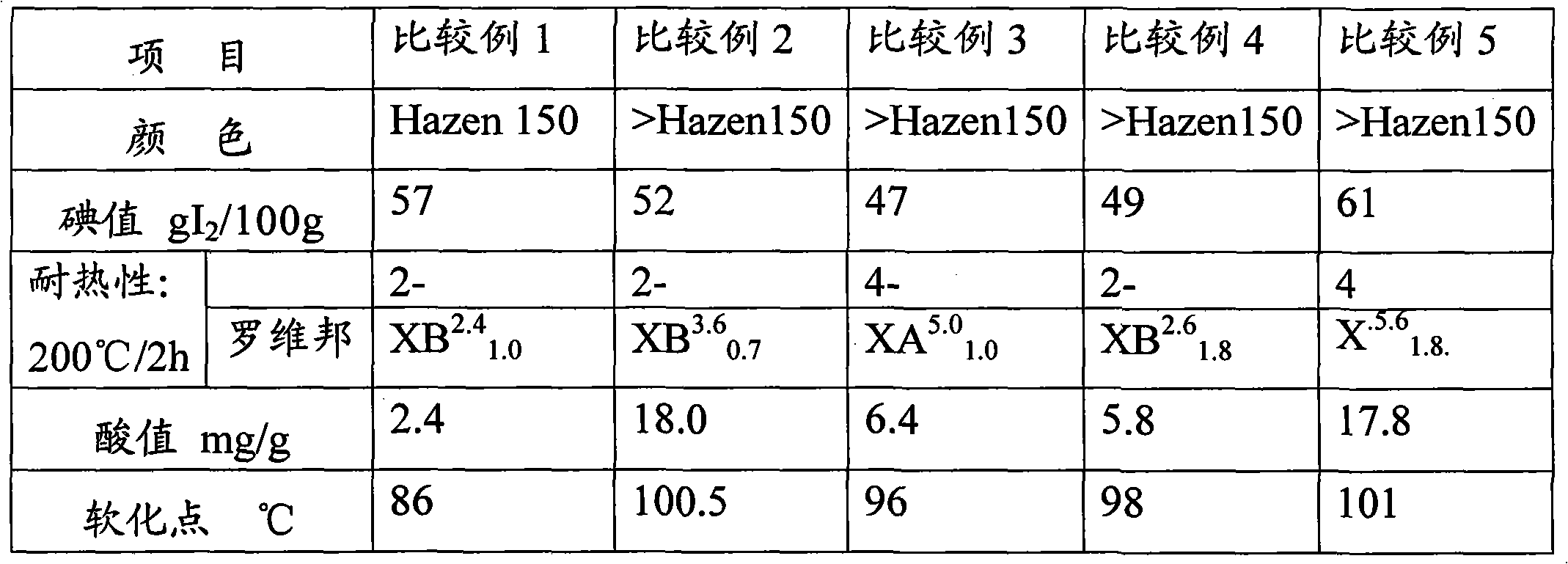

Method for preparing colorless hydrogenated rosin ester resin

ActiveCN102002321AHigh purityReduced chance of poisoningNatural resin chemical modificationAdhesiveDistillation

The invention relates to a method for preparing colorless hydrogenated rosin ester resin. Rosin ester obtained by esterifying rosin purified through distillation is used as a raw material, catalytic hydrogenation is carried out under the action of a solvent and a high activity catalyst, the solvent is separated through distillation, and the colorless hydrogenated rosin ester resin is obtained. The product comprises the following key indexes of: no more than 100 of Hasson color number, no more than 20 mg / g of acid value, 80 to 110 DEG C of softening point and 0 to 15 gI2 / 100g of iodine value. The product can substitute a colorless hydrogenated petroleum resin product to be applied to the high-end adhesive. The method for preparing the colorless hydrogenated rosin ester resin is simple and easy, and the prepared product has the advantages of shadow color, lower iodine value, higher stability and lower preparation cost when being compared with the traditional products.

Owner:广西梧州日成林产化工股份有限公司

Preparation for active octacosa alkanol and triaconta alkanol in rice bran

InactiveCN1439625AHigh purityLow iodine valueOrganic compound preparationHydroxy compound preparationTriacontanolChemistry

A process for prepairng octacosonal and triacontanol from rice bran, especially the rice bran wax includes such steps as refining rice bran wax, ultrasonic hydrolysis for 1 hr to extract emtrol, and molecular distilling for separating octacosanol and triacontanol. Its advantages are ultrasonic hydrolysis time decreased from 12-16 hr to 1 hr, and high purity of products (more than 80%).

Owner:JIANGNAN UNIV

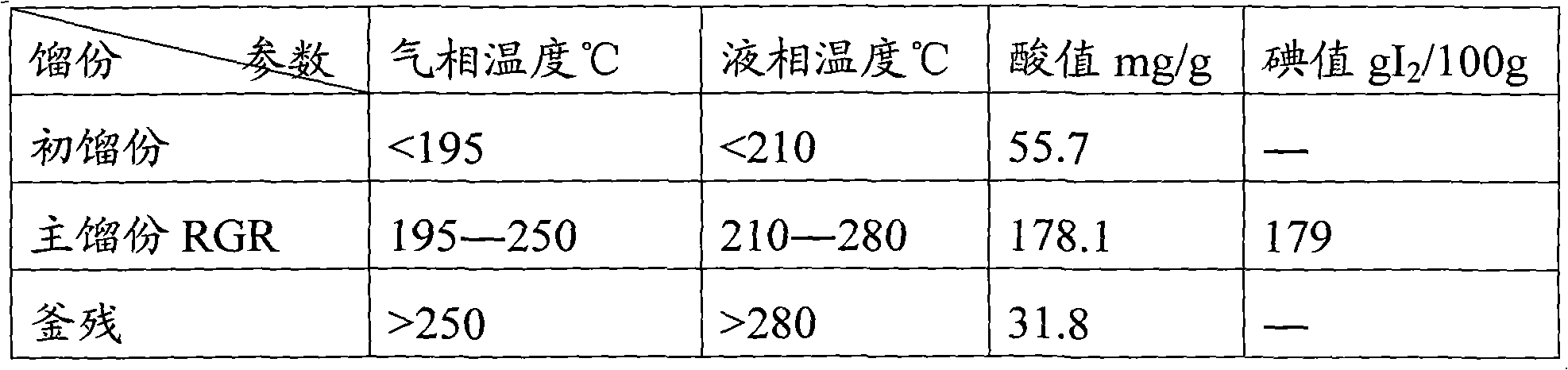

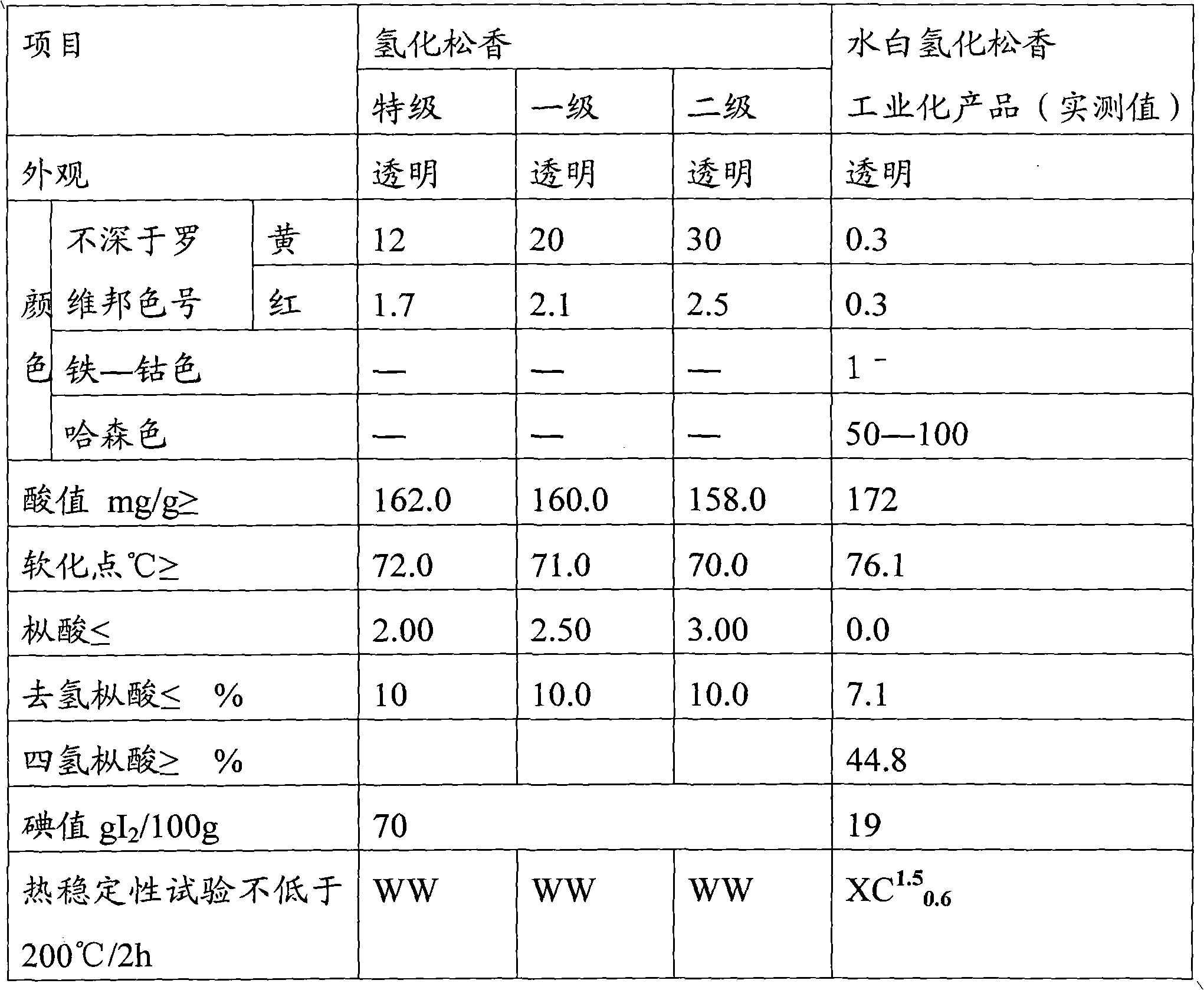

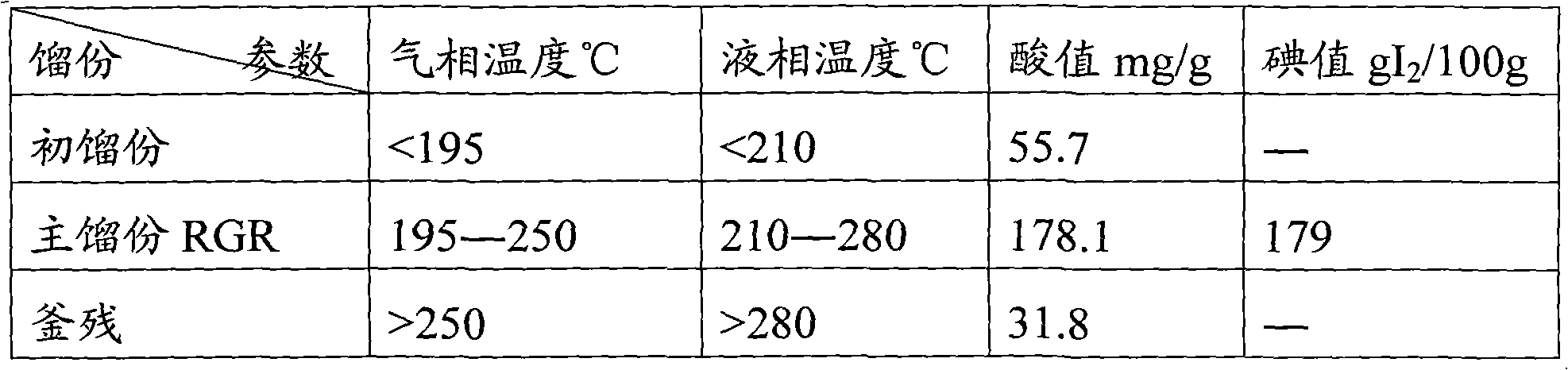

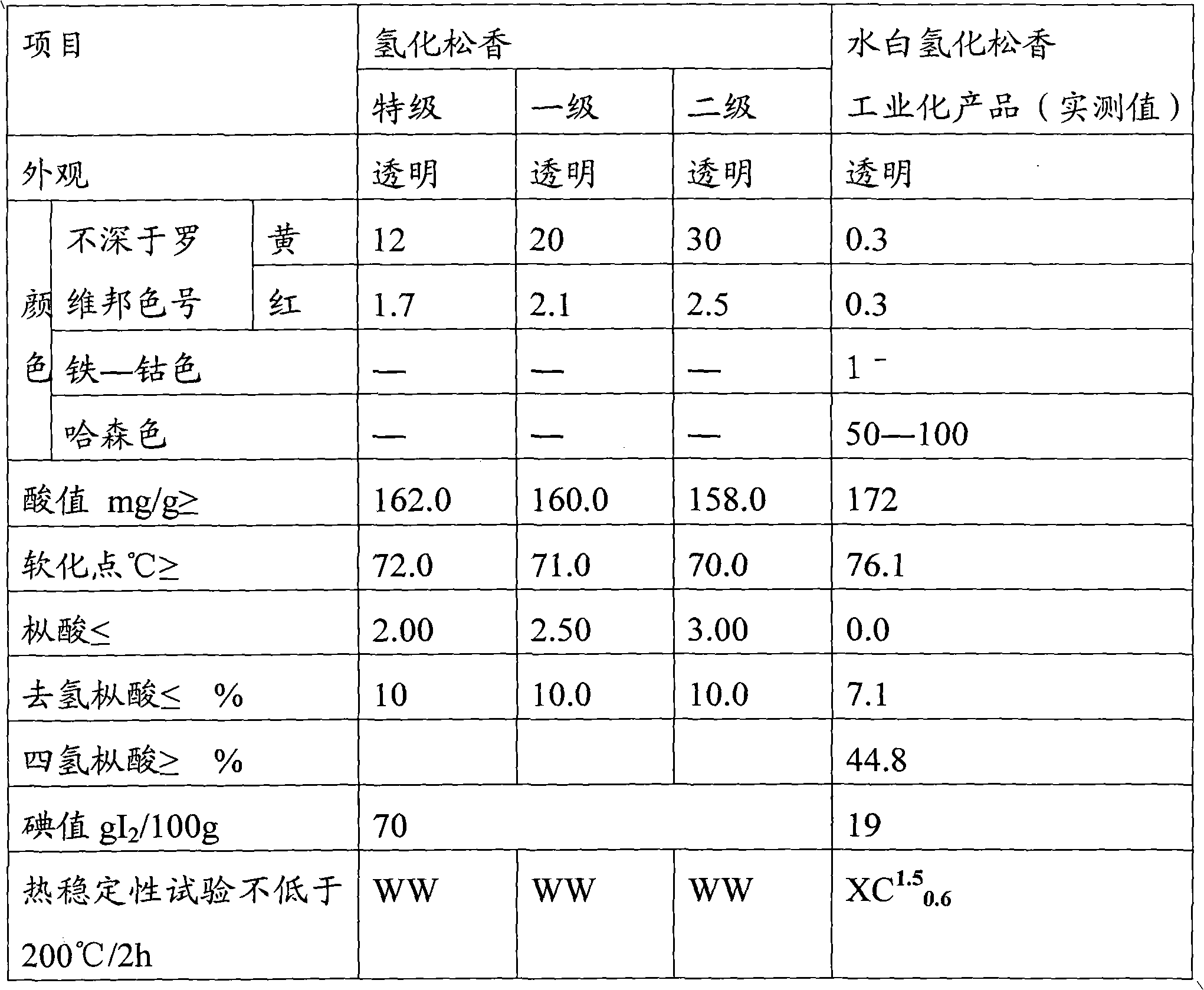

Method for producing water-white hydrogenated rosin

ActiveCN102070988ALow hydrogenation reaction temperatureRelieve pressureNatural resin chemical modificationDistillationSolvent

The invention relates to a method for producing water-white hydrogenated rosin, which comprises the following steps: using light color refined rosin obtained after purifying the rosin as hydrogenation raw materials, using a solvent for preparing solution, carrying out catalytic hydrogenation, then, separating out the solvent through distillation, and obtaining the water-white hydrogenated rosin. When the method provided by the invention is adopted, the water-white hydrogenated rosin with light color (the Lovibond color number of the yellow color is 0.3 to 1.0, and the Lovibond color number of the red color is 0.2 to 0.3), low iodine value and low abietic acid content can be obtained. Compared with the water-white hydrogenated rosin produced by a traditional method, the water-white hydrogenated rosin produced by the method provided by the invention has the advantages of lighter color, higher hydrogenation degree, better stability and lower cost, and the application value of products can be improved when the water-white hydrogenated rosin is applied to aspects such as electronics, paint, bonding agents, dyestuff and the like.

Owner:广西梧州日成林产化工股份有限公司

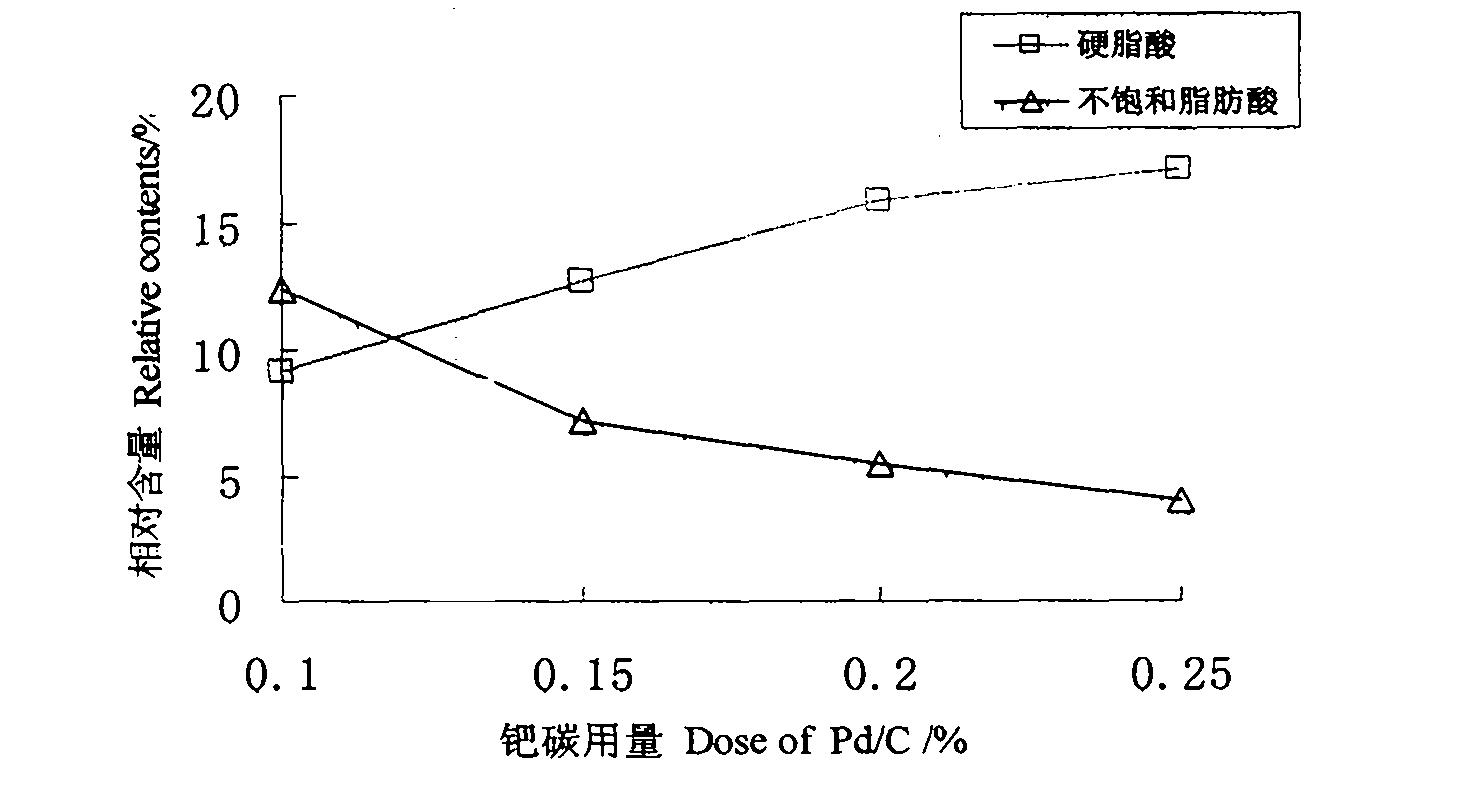

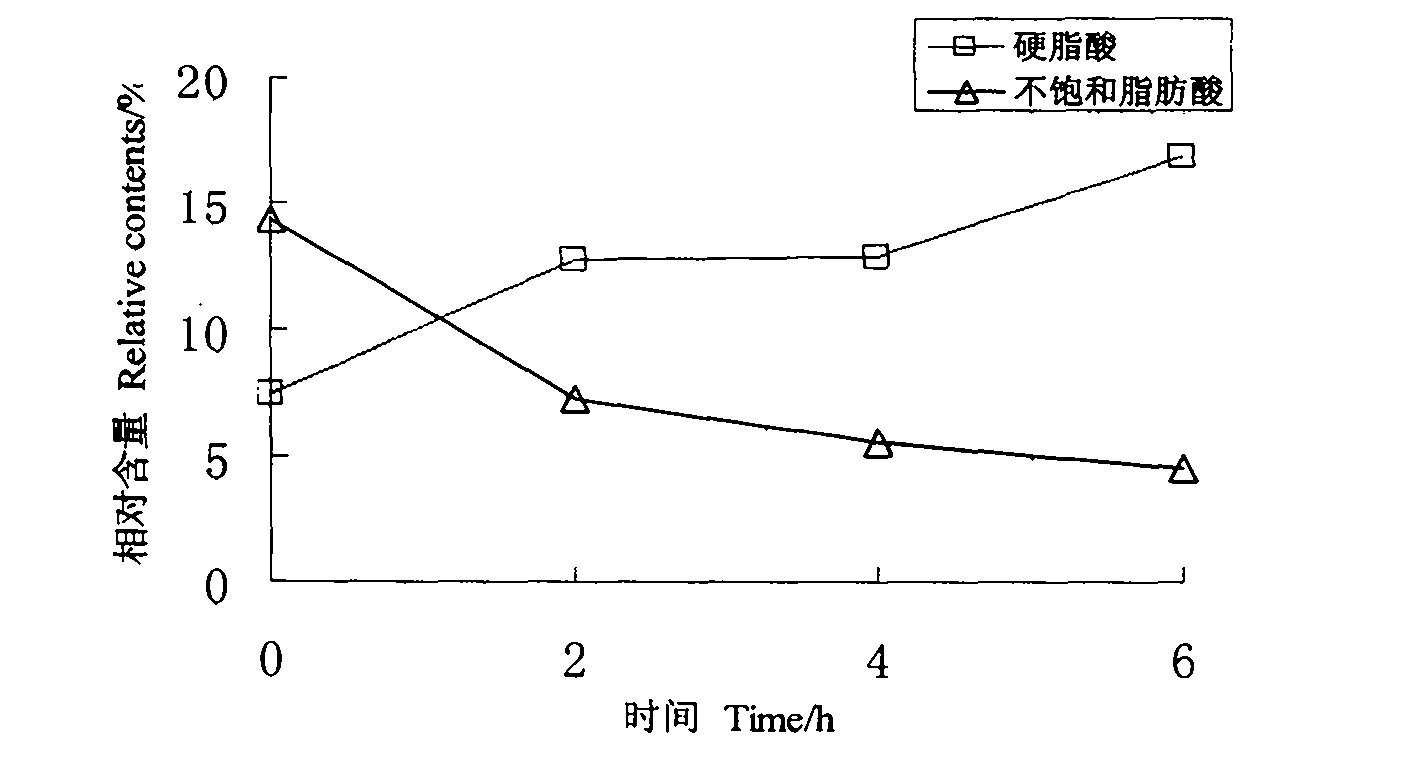

Method for preparing high-quality fine lacquer wax product

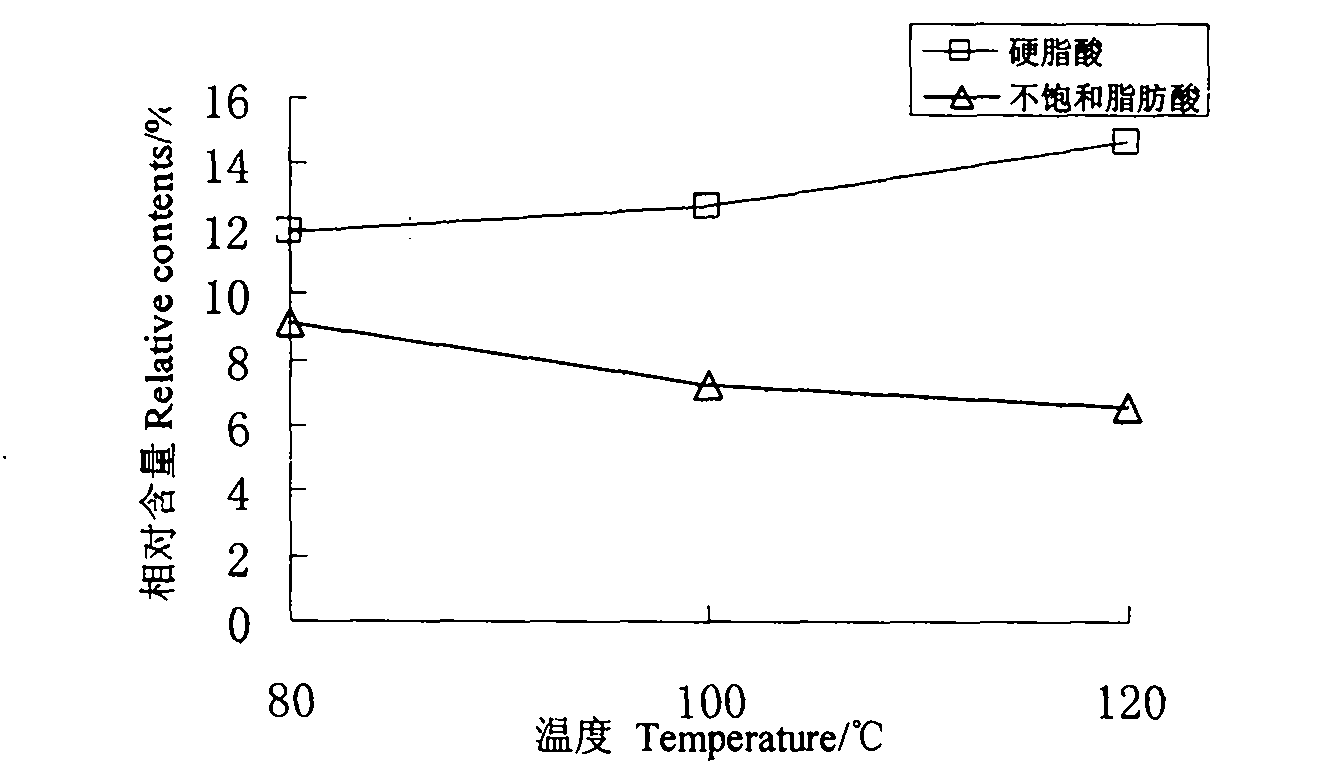

ActiveCN102329693APrevent mildewReduce moisture contentFatty substance recovery/refiningFatty substance recoveryPalladium on carbonLacquer

The invention discloses a method for preparing high-quality fine lacquer wax product, which comprises the following steps of: firstly, microwave drying lacquer seeds, separating skin and cores, and lixiviating the skin and flesh part of the lacquer seeds by using a non-polar solvent to obtain rough lacquer wax; heating and uniformly mixing the lacquer wax and a certain proportion of Pd / C catalyst in a high-temperature high-pressure reactor, charging hydrogen gas and maintaining a certain hydrogen gas pressure for reaction; after the reaction is completed, and filtering and discoloring the product while hot to obtain highly saturated lacquer wax; and detecting the variation of fatty acid content in the lacquer wax, by using gas chromatography. The method is simple and convenient, and the problems of low lacquer wax melting point, easy rancidity and the like caused by high content of unsaturated fatty acid in rough lacquer wax can be effectively solved. The obtained hydrogenated fine lacquer wax product has similar physical and chemical properties to Star Cherry-A white wax processed by Japan Araki Wax Manufacturing Company and can be widely applied to the field of daily chemicals.

Owner:NANJING ZHONGSEN BIOLOGICAL TECH CO LTD

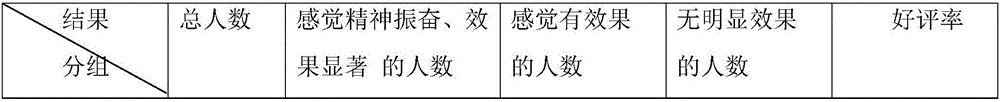

Oat and linolenic acid composite beverage and preparation method thereof

ActiveCN106721789AReduce heart diseasePrevent puffinessFood ingredient functionsEmulsionOmega 3 fatty acid

The invention relates to an oat and linolenic acid composite beverage, relates to a preparation method of the beverage, and belongs to the technical field of processing of other beverages. The oat and linolenic acid composite beverage is mainly prepared from the following raw materials in percentage by mass: 1-6% of oat, 1-8% of linseed oil, 2-3% of maltose, 0.2-0.6% of fructo-oligosaccharide, 1-3% of xylitol, 1-4% of cane sugar or starch syrup, 2-6% of coconut milk, 0.1-0.3% of a composite emulsion stabilizer, 0.005-0.01% of edible essence and 0.1-1% of sodium ascorbate. According to the oat and linolenic acid composite beverage disclosed by the invention, the oat is used as a main raw material, the linseed oil and the coconut milk are added, the specific composite emulsion stabilizer is matched, and a specific technology is used, so that the oat and linolenic acid composite beverage is prepared. High omega-3 fatty acid content of the oat beverage is guaranteed, and besides, a good stabilizing effect can be achieved. Under normal temperature, after being subjected to standing for 3 months, the oat and linolenic acid composite beverage does not generate precipitates, and is free of a layering phenomenon and the phenomenon that fat floats upwards.

Owner:蔡密林

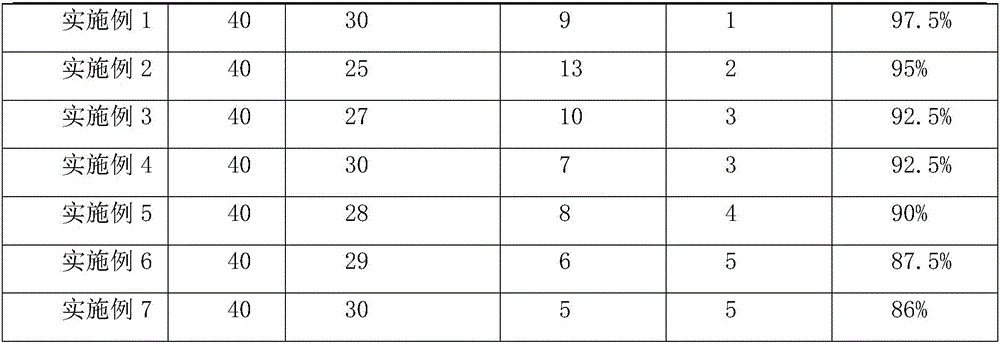

Method for separating and extracting isostearic acid from monomer acid

ActiveCN101544559ALow viscosityLow boiling pointCosmetic preparationsOrganic compound preparationDistillationDimer acid

The present invention discloses a method for separating and extracting isostearic acid from monomer acid. The present invention relates to a method for separating and extracting isostearic acid, in particular to a novel method for separating and extracting isostearic acid from monomer acid. The present invention provides a method for separating and extracting isostearic acid from monomer acid, which is suitable for use in commercial production. The method is characterized in: esterify the byproduct (monomer acid) obtain in production of dimer acid through bleaching earth catalytication process under medium pressure without catalyst to obtain monomer acid ester, treat by catalytic hydrogenation under medium pressure, and filter to obtain hydrogenised monomer acid ester; envelope with carbamide, filter, separate, and wash with water to obtain crude product of isostearic acid ester; perform molecular distillation to obtain refined isostearic acid ester, and then perform hydrolysis to obtain isostearic acid. Compared to the separation and extraction technique in the prior art, the present invention has the following advantages: the acidity and viscosity are low during hydrogenisation, and therefore the service life of catalyst is long, no nickel soap will be formed, and the corrosion to equipment is reduced; the product can be enveloped and separated by carbamide more easily; the distillation can be performed at a lower temperature; the iodine value of final product is low, the color is light, and the purity is high.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

Refining method for insect wax

InactiveCN101225345AImprove refining yieldHigh melting pointFatty substance recovery/refiningFatty substance recoveryWaxMinor metals

The invention discloses a refined method of Chinese wax, comprising 1) acid cleaning to removal impurity, which means acidic solution is adopted to removal the phospholipids and micro metal ion in the liquated raw wax; 2) adsorbing to decolor, which means the floridin and the silicon dioxide are adopted to decolor and removal the protein in the liquated raw Chinese wax under vacuum state. The refined method of Chinese wax has the advantages of simple technique and convention operation. The appearance of the made Chinese wax and the physicochemical index can reach the first wax standard set by < trading cooperative standards of P.R.C- Chinese wax [GH011-80] >, and also has the advantages of increasing the productive rate and the purity of the Chinese wax and lowering the productivity energy consumption.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

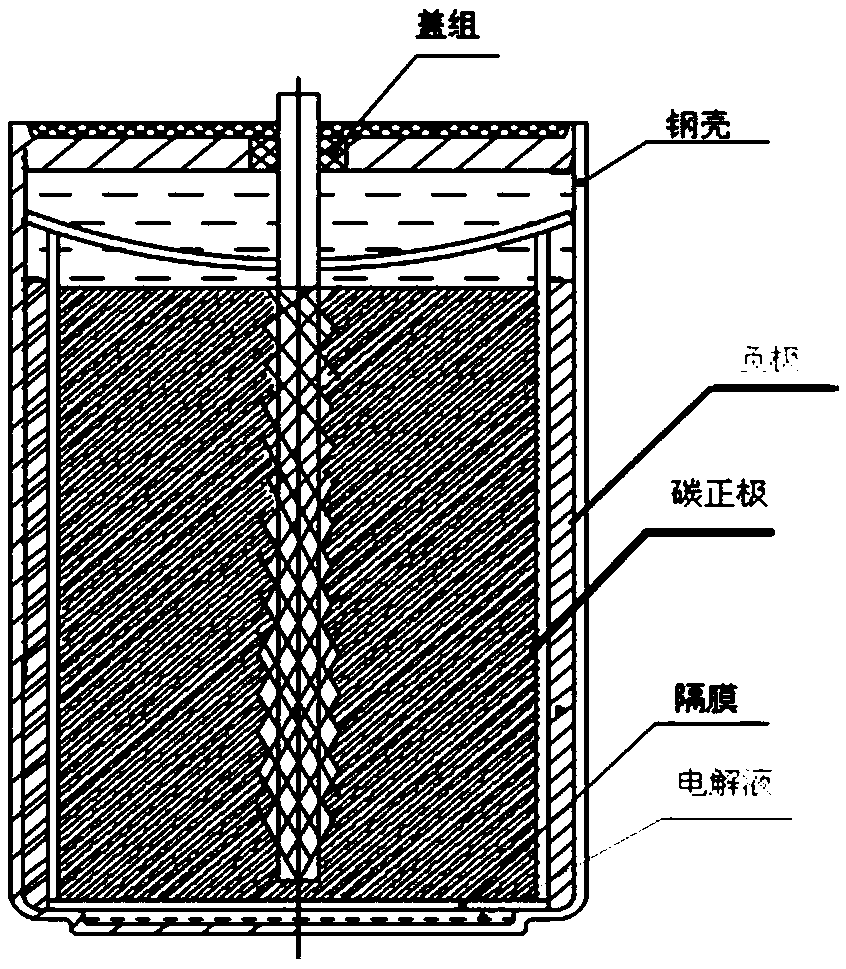

Positive electrode of lithium-thionyl chloride energy type battery and preparation method thereof and lithium-thionyl chloride energy type battery

ActiveCN109285990AHigh oil absorption valueImprove liquid absorption capacityNon-aqueous electrolyte cellsPrimary cell electrodesSolventPelletizing

The invention discloses a positive electrode of a lithium-thionyl chloride energy type battery, a preparation method thereof and the lithium-thionyl chloride energy type battery. The carbon positive electrode is composed of acetylene black, a polytetrafluoroethylene emulsion, a novel carbon material and a solvent, the mass ratio of the acetylene black to the polytetrafluoroethylene emulsion to thenovel carbon material to the solvent is 10: (1.8 to 2.1) ): (0.8-1.0): (45.5-48), and the carbon positive electrode is prepared by uniformly mixing the acetylene black, the polytetrafluoroethylene emulsion, the novel carbon material and the solvent through a low-speed and three-dimensional mixer by means of granulation and drying. The carbon positive electrode of the lithium-thionyl chloride energy type battery has improved liquid absorption capacity and liquid retention capacity, effectively solves the problem of capacity difference caused by the difference of electrolyte flow when the battery is arranged transversely and inverted, and improves the environmental adaptability of the battery.

Owner:武汉中原长江科技发展有限公司

Drinking Straw

InactiveUS20100221389A1Low levelRisk minimizationAnimal feeding stuffSausage casingsMedicineDrinking straw

A combination of a container in which is disposed a liquid composition in the form of a beverage or liquid food and a drinking straw comprises a hollow elongate tube through which liquid may be drawn by suction. The tube has an outer surface and an inner surface. The combination includes an iron component and an oxidisable oil. The iron component is disposed inside the drinking straw and the oxidisable oil is in the liquid composition. The straw alone is also an aspect of the invention.

Owner:FRENKEN LEO GERARDUS +2

Hydrogenated product of beef tallow, fat composite containing the same and method for preventing fat composite from generating particles

The invention relates to a hydrogenated product of beef tallow, which is obtained after raw material beef tallow is hydrogenated. Compared with the iodine value of the raw material beef tallow, the iodine value of the hydrogenated product is decreased by 5-53. The invention additionally provides a fat composite containing the hydrogenated product. The invention further provides a hydrogenation method for the beef tallow and a method for preventing the fat composite containing the beef tallow from generating particles under an environment with low-temperature and the a storage condition with temperature fluctuation. Through hydrogenating and modifying fat materials containing the beef tallow or the fat composite, the invention can effectively solve the problem that the products are apt to generate particles under the environment with low-temperature and the environment with temperature fluctuation.

Owner:嘉里特种油脂(上海)有限公司

Preparation for active octacosa alkanol and triaconta alkanol in rice bran

InactiveCN1257142CIncrease hydrolysis rateSolve the problem of difficult hydrolysisOrganic compound preparationHydroxy compound preparationFood additiveDistillation

The invention discloses a method for preparing rice bran active substances octacosanol and triacontanol, which belongs to the comprehensive utilization of rice bran, especially the comprehensive utilization of rice bran wax. The present invention uses crude bran wax as a raw material, and after refining the crude bran wax, adopts ultrasonic hydrolysis of rice bran wax, extraction of fatty alcohol, and separation of octacosanol and triacontanol by molecular distillation technology, a product with a purity greater than 80% is prepared. . The invention uses ultrasonic hydrolysis of rice bran wax and molecular distillation technology to separate octacosanol and triacontanol, which belongs to pioneering research, and establishes a complete set of technology for extracting octacosanol and triacontanol from rice bran wax. The hydrolysis reaction is shortened by more than 10 hours compared with the general method, shortened from 12-16 hours to less than 1 hour, and the hydrolysis rate has been increased by 2 times; the pilot test of molecular distillation has been carried out, and the preparation of high-purity biologically active substances octacosanol, Triacontanol breakthrough. The product has high purity, low iodine value, and heavy metal and microbial content meet the requirements of food additives, creating conditions for the development and utilization of high-carbon alcohols in the future.

Owner:JIANGNAN UNIV

Method of reducing iodine value of glyceride

ActiveCN108865445ALow iodine valueIncrease contentFatty acid esterificationFatty acids production/refiningSide reactionPolyunsaturated fatty acid

The invention relates to the technical field of synthesis and processing of glyceride, and specifically relates to a preparation method of reducing iodine value of glyceride. The preparation method ofreducing iodine value of glyceride includes catalytic reaction of glyceride, saturated fatty acid and alkali under the action of lipase to prepare the glyceride with low iodine value; the iodine value of glyceride is effectively reduced by sufficient amount of saturated fatty acid residues provided by salts of saturated fatty acids that are produced by corresponding saturated fatty acid and alkali in-situ and by catalytic action of non-directed lipase to allow milder reaction conditions with less side reactions.

Owner:CABIO BIOTECH WUHAN CO LTD

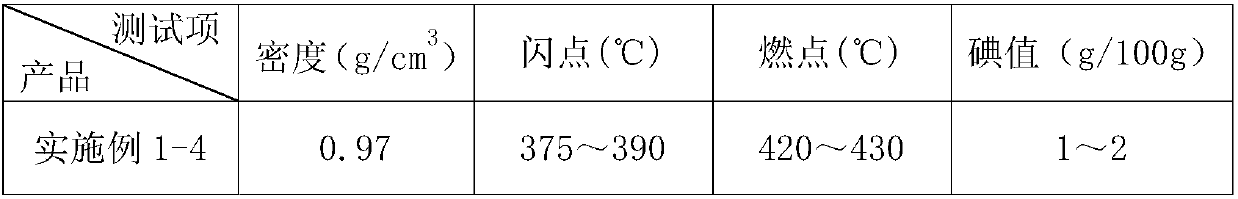

Preparation method of hydrogenated dimer acid

ActiveCN107602371AHigh dimer contentLight colorOrganic compound preparationCarboxylic preparation by ozone oxidationWater vaporPhosphoric acid

The invention discloses a preparation method of hydrogenated dimer acid. The preparation method comprises the following steps: adding cottonseed oil fatty acid, dimethyl formamide, deionized water, sodium carbonate and a catalyst into a reaction still, introducing nitrogen, carrying out heating and pressurization, stirring for 3 to 4 h, adding a phosphoric acid solution, stirring, then warming, gradually reducing pressure inside the reaction still, discharging water vapor, when the pressure is decreased to be 1 atm, stopping heating, and standing for cooling; then adding the solution into a molecular still, adjusting the vacuum degree, and collecting residual liquid inside the molecular still 1 to 2 h later; adding the residual liquid into a high pressure still, adding the solvent and thecatalyst in sequence, introducing hydrogen, adjusting pressure and temperature, and stirring until the iodine value is smaller than or equal to 8 g per 100 g so as to obtain the hydrogenated dimer acid. The hydrogenated dimer acid prepared by the method has the character high dimer content, low in color and luster, low in iodine value, high in flash pint, high ignition point and high heat stability, and can be widely applied to mineral oil additives, surface active agents, waterproof agents, rocket propellants and the like.

Owner:ANQING HONGTAI NEW MATERIAL

Method for producing water-white hydrogenated rosin

ActiveCN102070988BIncrease the degree of hydrogenationReduce contentNatural resin chemical modificationDistillationSolvent

The invention relates to a method for producing water-white hydrogenated rosin, which comprises the following steps: using light color refined rosin obtained after purifying the rosin as hydrogenation raw materials, using a solvent for preparing solution, carrying out catalytic hydrogenation, then, separating out the solvent through distillation, and obtaining the water-white hydrogenated rosin. When the method provided by the invention is adopted, the water-white hydrogenated rosin with light color (the Lovibond color number of the yellow color is 0.3 to 1.0, and the Lovibond color number of the red color is 0.2 to 0.3), low iodine value and low abietic acid content can be obtained. Compared with the water-white hydrogenated rosin produced by a traditional method, the water-white hydrogenated rosin produced by the method provided by the invention has the advantages of lighter color, higher hydrogenation degree, better stability and lower cost, and the application value of products can be improved when the water-white hydrogenated rosin is applied to aspects such as electronics, paint, bonding agents, dyestuff and the like.

Owner:广西梧州日成林产化工股份有限公司

Preparation method of oil-fat hydrogenation nano catalyst

InactiveCN104437582AEasy to operateImprove performanceFatty acid hydrogenationPhysical/chemical process catalystsNano catalystHydrogenation reaction

The invention relates to a method for preparing an oil-fat hydrogenation nano catalyst by using nano calcium carbonate. The method is mainly characterized by breaking through the use of a conventional catalyst carrier and adopting nano calcium carbonate which is economical and easily available as a catalyst carrier. The catalyst preparation is simple in operation, the performance of the catalyst is stable, and the hydrogenation effect can reach an industrial requirement level. The catalyst prepared by loading an active ingredient, namely nickel and one or more than one of auxiliary agents, namely aluminum, cobalt, zinc, iron and the like to a carrier namely nano calcium carbonate can be used for hydrogenation reaction of unsaturated fatty acid including branched chain unsaturated fatty acid in natural oil and fat.

Owner:JIANGNAN UNIV

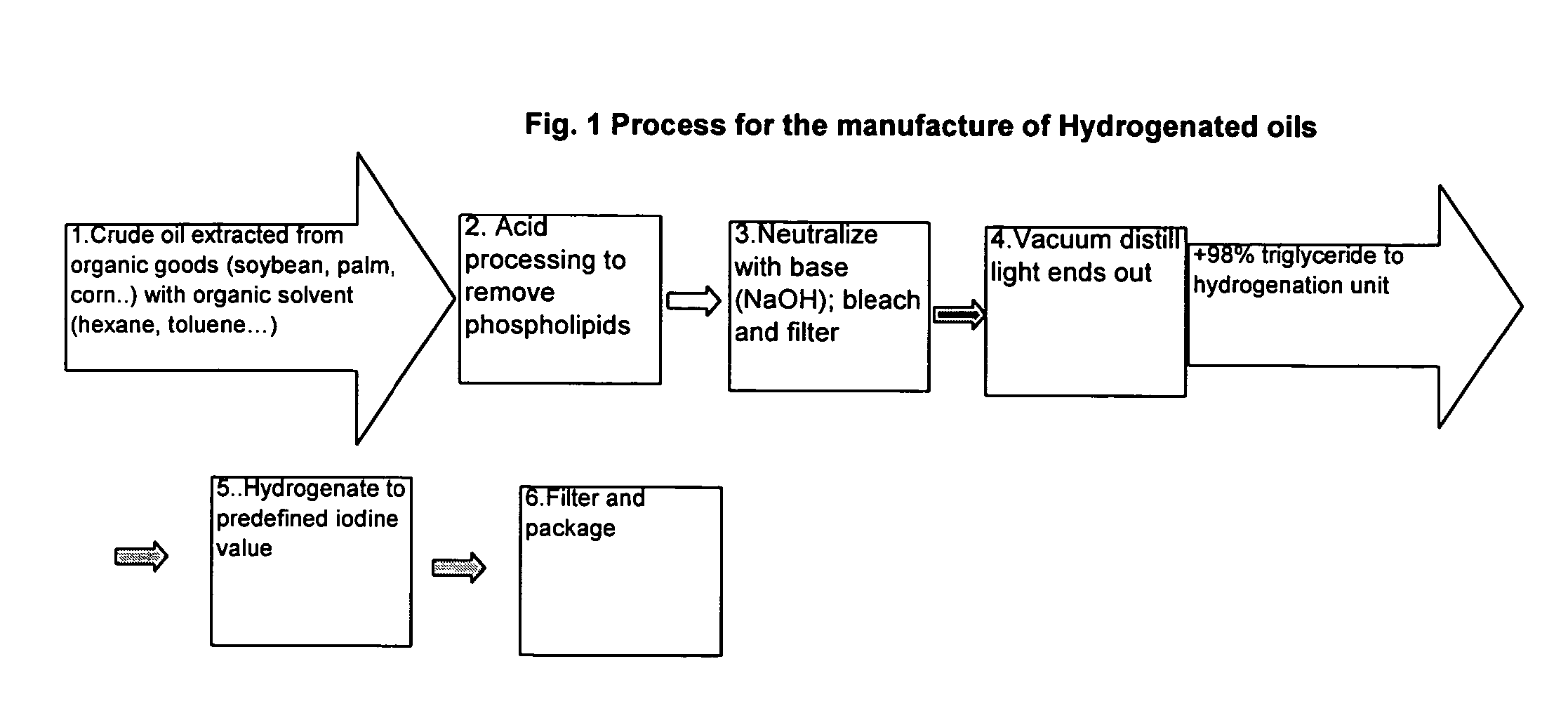

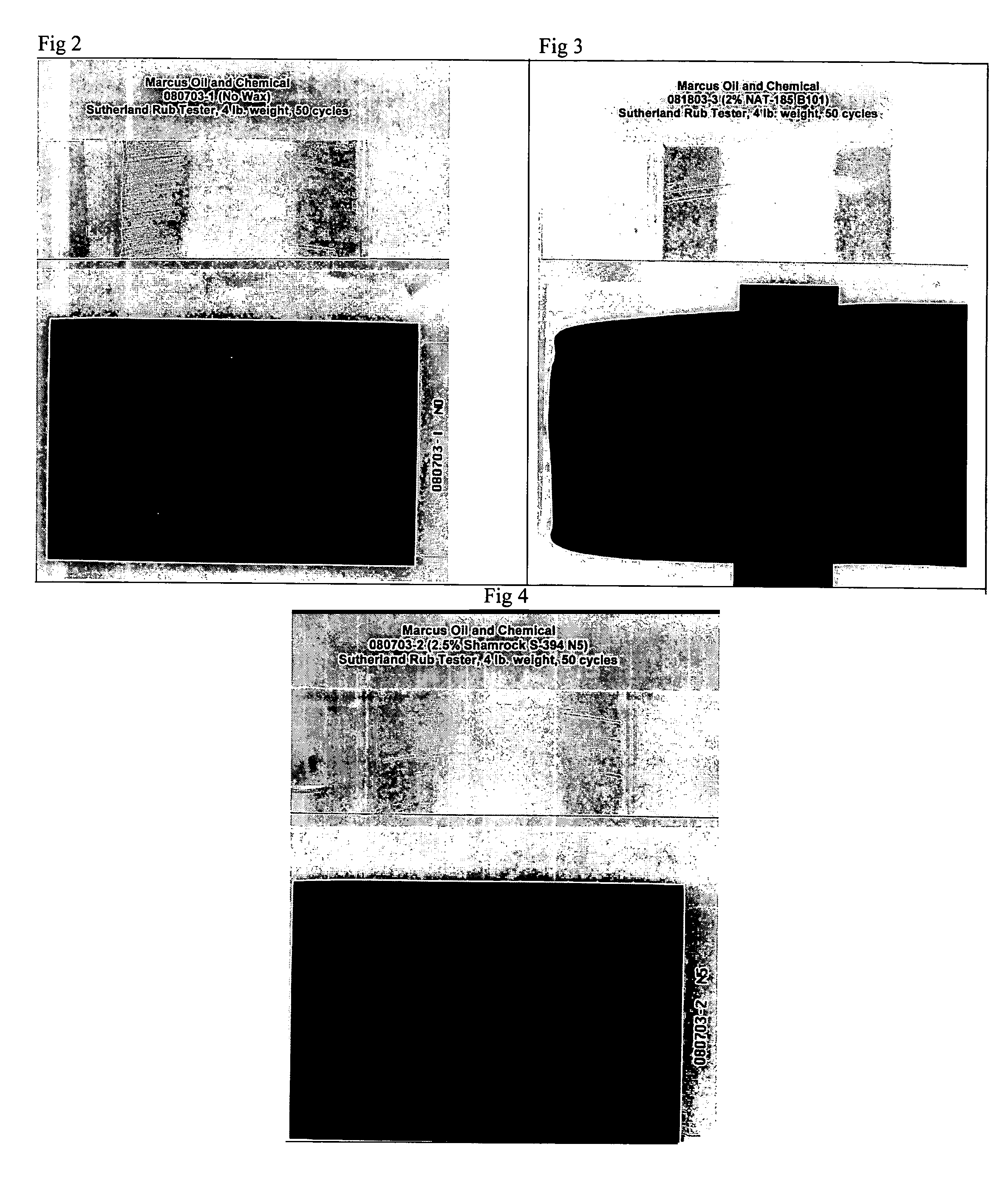

Wax for reducing mar and abrasion in inks and coatings

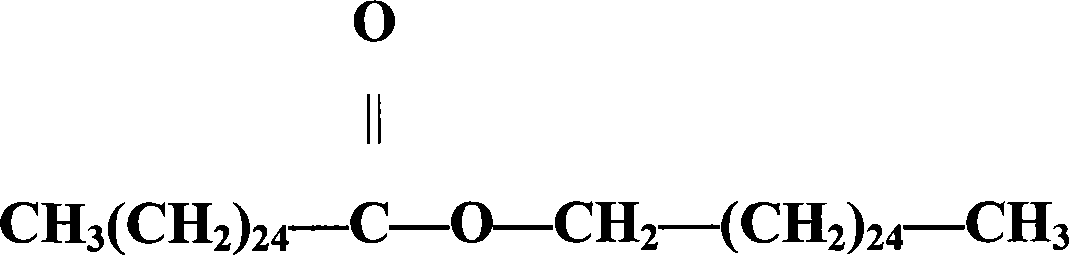

InactiveUS8138250B2Good dispersionLow iodine valueCarboxylic acid esters preparationPaper coatingCelluloseWax

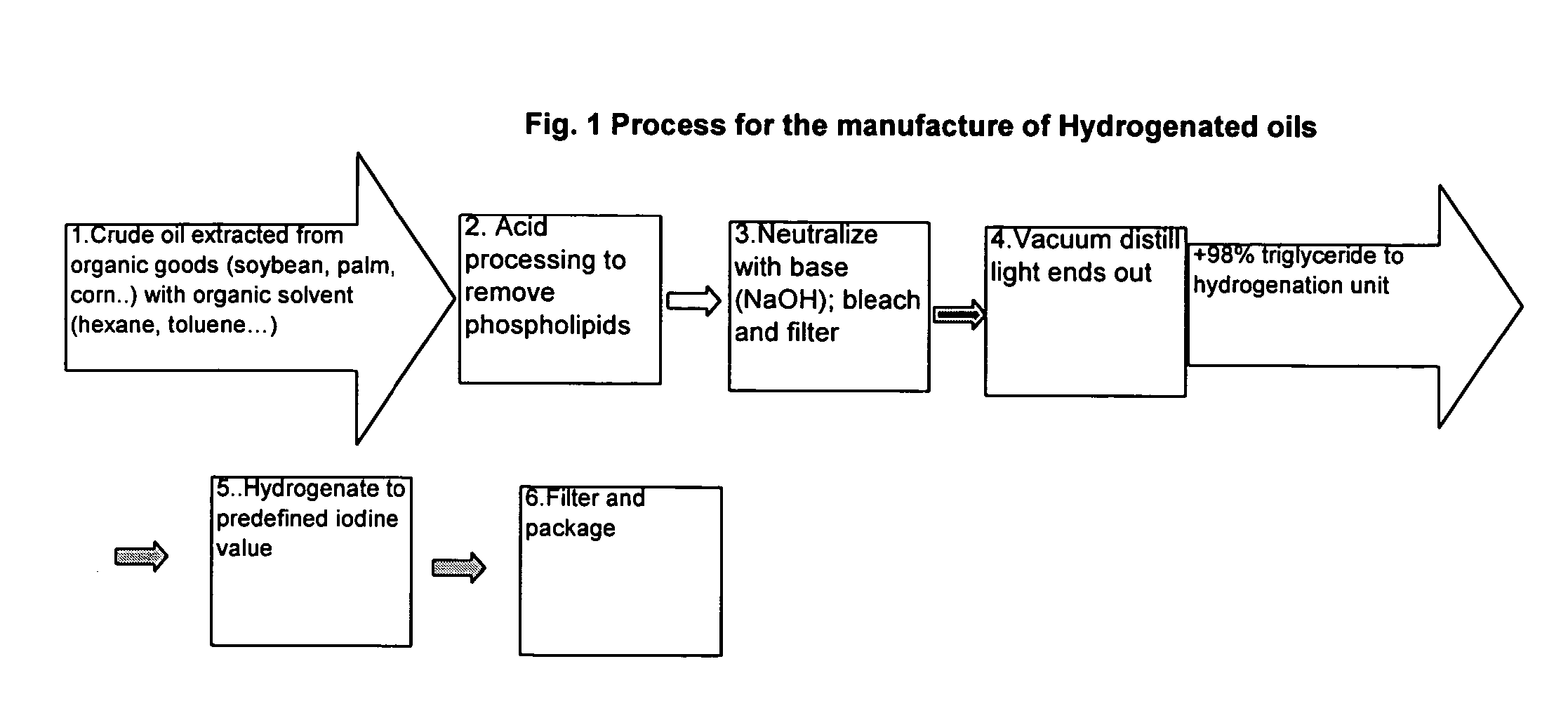

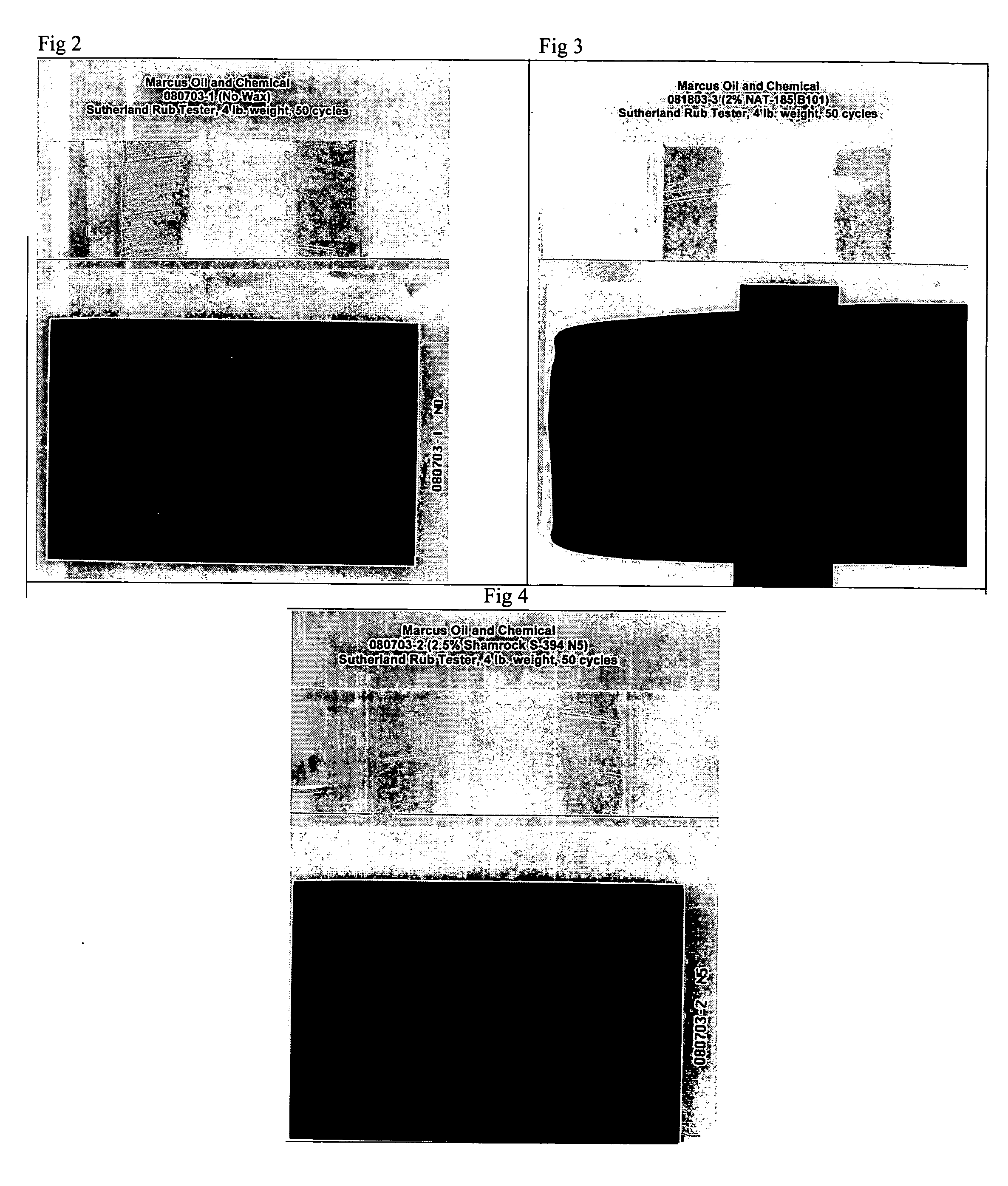

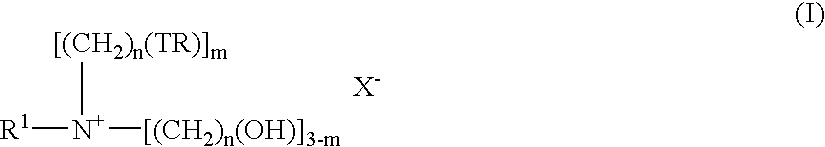

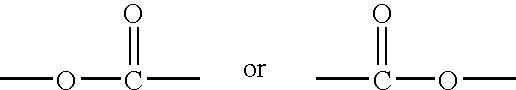

Waxes prepared from hydrogenated plant oils, such as castor and soybean, are formulated into aqueous ink and paper coating compositions. Ink compositions comprising these waxes and evaluated for their resistance to mar and abrasion achieved rub resistance and slip performance comparable to compositions utilizing conventional wax additives, which are generally derived from petroleum. The waxes in the inventive compositions have a low iodine value (ranging from approximately 2 to approximately 5), and a melting point between approximately 120 degrees to approximately 190 degrees F. (Mettler Drop Point). These naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of inks and coatings for paper and cellulosic products.

Owner:HRD CORP

Preparation method of biodegradable drawing oil

The invention discloses a preparation method of biodegradable drawing oil, and belongs to the technical field of drawing oil preparation. According to the preparation method, with catalysis of sodiumhydroxide, lard oil and palm oil are mixed and react with methanol to generate palm oil fatty acid methyl ester; the content of double bonds in the mixed oil is reduced, and the oxidation stability ofthe drawing oil is improved; since the ester synthesized oil has relatively high biodegradability, carbon dioxide and water are generated during biodegradation process, thus the biodegradability of the drawing oil is enhanced; by implementing acetylation modification on the group-OH at the terminal of polylactic acid by use of acetic anhydride and pyridine, the thermal stability or oxidation stability of polylactic acid is improved, and the inside of the drawing oil is effectively filled with the polylactic acid, thereby further improving the biodegradability and oxidation stability of the drawing oil; an anti-foaming agent, an antioxidant, a viscous agent and a stabilizer are added to form a layer of oxidation-stable protective film at high temperature, thereby improving the oxidation stability of the drawing oil and realizing a broad application prospect.

Owner:田秋珍

A kind of oatmeal compound linolenic acid beverage and preparation method thereof

ActiveCN106721789BReduce heart diseasePrevent puffinessFood ingredient functionsBiotechnologyFructose

The invention relates to an oatmeal compound linolenic acid beverage and a preparation method of the beverage, which belongs to the technical field of other beverage processing. The oat compound linolenic acid beverage is mainly prepared from raw materials including the following mass percentages: oat 1-6%, linseed oil 1-8%, maltose 2-3%, fructooligosaccharide 0.2-0.6%, xylitol 1 ‑3%, sucrose or starch syrup 1‑4%, coconut milk 2‑6%, compound emulsion stabilizer 0.1‑0.3%, food flavor 0.005‑0.01%, sodium ascorbate 0.1‑1%. The present invention uses oats as the main raw material, adds linseed oil and coconut milk, cooperates with a specific compound emulsification stabilizer, and adopts a specific process to prepare, while ensuring a high content of omega-3 fatty acids in the oat beverage, it can achieve a good The stable effect, standing at room temperature for 3 months without precipitation, stratification, fat floating phenomenon.

Owner:蔡密林

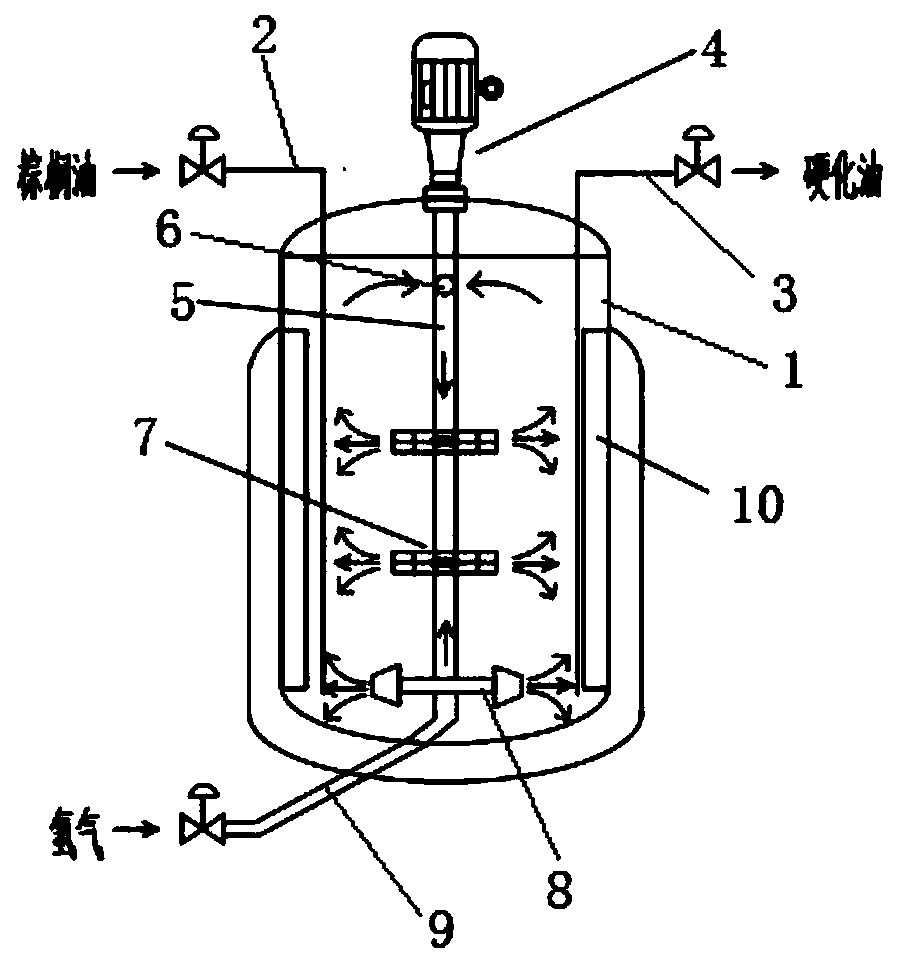

Hydrogenation reaction vessel

InactiveCN110394126AReasonable structureEasy to useChemical/physical processesElectric machineryImpeller

The invention discloses a hydrogenation reaction vessel. The hydrogenation reaction vessel comprises a reaction vessel main body; the reaction vessel main body is provided with a feeding pipeline anda discharge pipeline; the feeding pipeline is used for introduction of palm oil, and the discharge pipeline is used for discharging of hydrogenated oil; the upper end of the reaction vessel main bodyis provided with a stirring motor; the stirring motor is provided with a stirring shaft; the stirring shaft is designed to stretch to the bottom of the reaction vessel main body, and is of a hollow structure; the upper end of the stirring shaft is provided with a gas inlet hole; the stirring shaft is provided with hollow vane wheels which are communicated with the internal part of the stirring shaft; the hollow vane wheels are provided with gas outlets; the bottom of the stirring shaft is provided with a distributor; the distributor is communicated with the internal part of the stirring shaft;the lower end of the stirring shaft is connected with a hydrogen gas pipeline; and the hydrogen gas pipeline does not rotate with the stirring shaft. According to the hydrogenation reaction vessel, hydrogen gas is introduced into the stirring shaft through the bottom, and is distributed in oil phase using the distributor, at the same time, high speed rotation of the vane wheels is driven, upper hydrogen gas is inhalated through the gas inlets of the stirring shaft, and is distributed in oil phase through gas outlets of the vane wheels, so that reaction effect is ensured.

Owner:SHANGHAI SOAP GRP RUGAO

Snake abdomen scale lower fat and extraction method and application thereof

InactiveCN105733795AFix the problem of reduced efficacyHigh in saturated fatty acidsCosmetic preparationsToilet preparationsAbdomen skinSkin elasticity

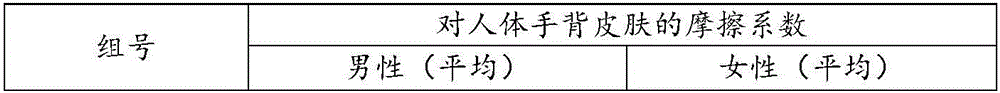

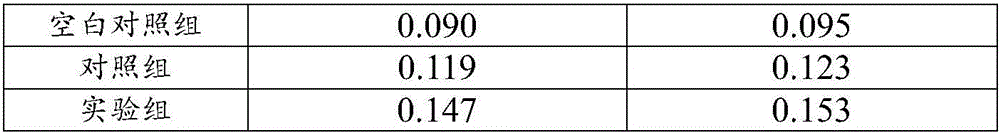

The invention relates to snake abdomen scale lower fat and an extraction method and application thereof.The extraction method includes following steps: mincing abdomen skin of a scaled snake to obtain a scaled snake abdomen skin minced product; adding the scaled snake abdomen skin minced product into water, and protease for enzymolysis to obtain a scaled snake abdomen skin enzymolysis product; centrifuging the scaled snake abdomen skin enzymolysis product, and taking supernate for oil-water separation to obtain a snake abdomen scale lower fat crude product; adding the snake abdomen scale lower fat crude product into an ether solvent, and performing microwave extraction and concentration to obtain the snake abdomen scale lower fat.The snake abdomen scale lower fat obtained by the method is high in saturated fatty acid content and low in unsaturated fatty acid content, iodine value, acid value and saponification value, friction coefficient of human hand back skin is increased remarkably, water content of the human hand back skin is increased remarkably, and the snake abdomen scale lower fat has a moisturizing function; the snake abdomen scale lower fat has efficacy of protecting skin, improving skin elasticity, nourishing skin and improving skin smoothness when being used for preparing products having skin protecting effect.

Owner:克劳丽化妆品股份有限公司

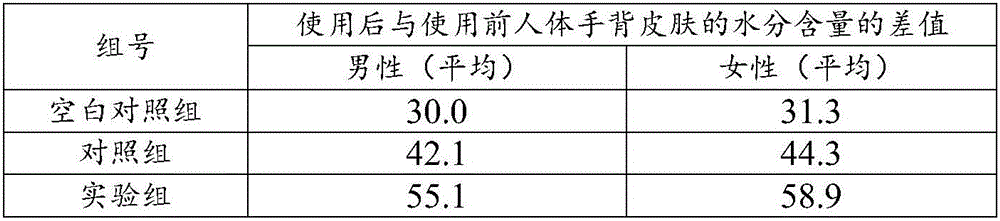

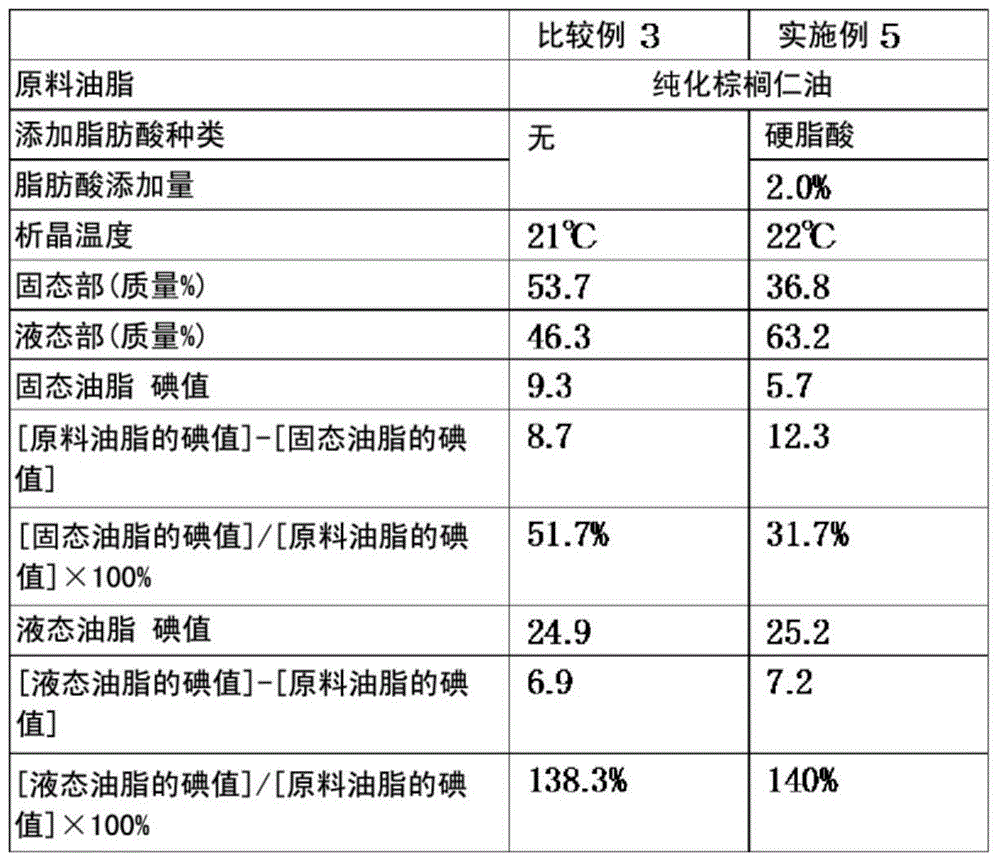

Method for producing oil or fat

InactiveCN104640963ALow iodine valueFatty-oils/fats/waxes solidificationFatty-oils/fats refiningOil and greaseFatty acid

The purpose of the present invention is to provide a method for producing the solid oil or fat having a specified iodine value. Specifically provided is a method for producing the solid oil or fat, characterized by comprising the steps of: (1) mixing a lauric oil or fat with a fatty acid having 14 to 22 carbon atoms and then heating / melting the resultant mixture, wherein the amount of the fatty acid is 0.5 to 15 mass% relative to the total mass of the lauric oil or fat and the fatty acid; (2) cooling the heated / melted product produced by the above-mentioned heating / melting procedure to produce a crystallized product; (3) subjecting the crystallized product to a solid / liquid separation procedure to separate the crystallized product into a solid matter and a liquid matter; and (4) removing the fatty acid from the solid matter to produce the solid oil or fat.

Owner:THE NISSHIN OILLIO GRP LTD

Liquid vegetable unsaturated alcohol and process for producing the same

ActiveUS7518022B2Excellent retention of liquidityImproved color stabilityFatty oils/acids recovery from wasteCosmetic preparationsPalm kernel oilVegetable oil

The invention is directed to liquid vegetable unsaturated alcohol mixture having an iodine value of 88 to 100 and a cloud point less than 7° C., the unsaturated alcohol mixture being prepared by reduction of a vegetable unsaturated fatty acid mixture and / or an alkyl ester thereof in the presence of a zinc-type catalyst having a copper content of 30 ppm or less, the vegetable unsaturated fatty acid mixture being prepared from at least one vegetable oil selected from the group consisting of palm oil, coconut oil and palm kernel oil. The invention also concerns a liquid vegetable unsaturated alcohol mixture having an iodine value of 88 to 100, a cloud point less than 7° C. or lower and a conjugated diene content of 1 wt. % or less.

Owner:NEW JAPAN CHEM CO

Grease for quick-frozen food

InactiveCN107494768ALow acid valueLow iodine valueEdible oils/fatsFatty acid glycerol estersRapeseed

The invention discloses an oil for quick-frozen food. The composition of the oil includes: lard, palm oil, rapeseed oil, olive oil, wheat flour, starch, glyceryl stearate, sesame oil and water. The oil for quick-frozen food of the invention has good quality and is beneficial to safeguard human health.

Owner:苍溪县峻绿食品有限公司

Method for preparing sulfated methyl ester by ionic liquid catalysis method

ActiveCN102382015AReduce manufacturing costReduce viscosityOrganic-compounds/hydrides/coordination-complexes catalystsSulfuric acid esters preparationIodine valueCarbonation

The invention relates to a method for preparing sulfated methyl ester by an ionic liquid catalysis method, and relates to the technical field of preparation of sulfated methyl ester by ionic liquid catalysis. The method comprises the following steps that: fatty acid methyl ester is used as a raw material, and a sulfated fatty acid methyl ester is prepared by an alkyl sulfonic acid pyridine ionic liquid catalyst under atmospheric pressure at a reaction temperature of 20 to 40 DEG C; the ionic liquid catalyst is added to the fatty acid methyl ester to be stirred, and the titration speed of sulfuric acid is controlled, so that the sulfuric acid is subjected to a sulphation reaction at a specified temperature in a water bath with a constant temperature; the reaction liquid in the steps is poured out, is placed in a separatory funnel, and is washed with 10wt% salt water until the reaction liquid is neutral. The method had the following advantages that: the iodine value of a product is small and can reach to 42.45 (the iodine value of the fatty acid methyl ester is about 110); the viscosity of biodiesel as a raw material is small, so that the mobility of the product is better, and the proportion of concentrated sulfuric acid is increased. The catalyst has good activity, the used amount of the catalyst is few, the carbonation can be reduced, the color of the product is lighter; the reaction conditions are mild, and the reaction time is short.

Owner:溧阳常大技术转移中心有限公司

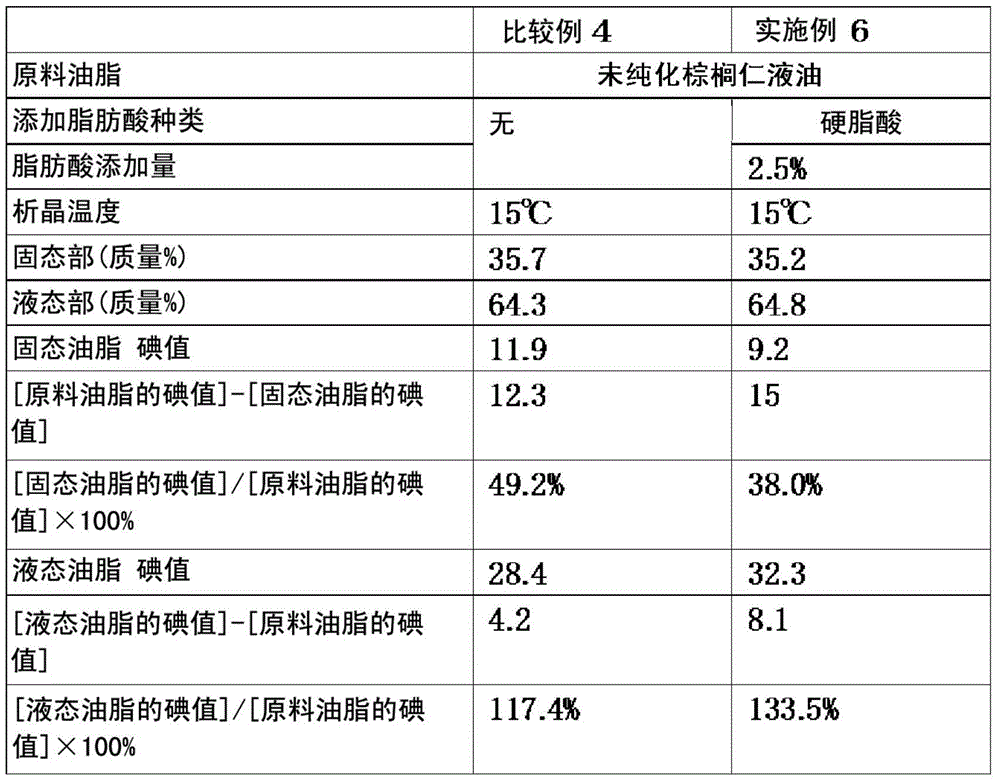

Method for separating and extracting isostearic acid from monomer acid

ActiveCN101544559BLow viscosityLow boiling pointCosmetic preparationsOrganic compound preparationDistillationDimer acid

The present invention discloses a method for separating and extracting isostearic acid from monomer acid. The present invention relates to a method for separating and extracting isostearic acid, in particular to a novel method for separating and extracting isostearic acid from monomer acid. The present invention provides a method for separating and extracting isostearic acid from monomer acid, which is suitable for use in commercial production. The method is characterized in: esterify the byproduct (monomer acid) obtain in production of dimer acid through bleaching earth catalytication process under medium pressure without catalyst to obtain monomer acid ester, treat by catalytic hydrogenation under medium pressure, and filter to obtain hydrogenised monomer acid ester; envelope with carbamide, filter, separate, and wash with water to obtain crude product of isostearic acid ester; perform molecular distillation to obtain refined isostearic acid ester, and then perform hydrolysis to obtain isostearic acid. Compared to the separation and extraction technique in the prior art, the present invention has the following advantages: the acidity and viscosity are low during hydrogenisation, and therefore the service life of catalyst is long, no nickel soap will be formed, and the corrosion to equipment is reduced; the product can be enveloped and separated by carbamide more easily; the distillation can be performed at a lower temperature; the iodine value of final product is low, the color is light, and the purity is high.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

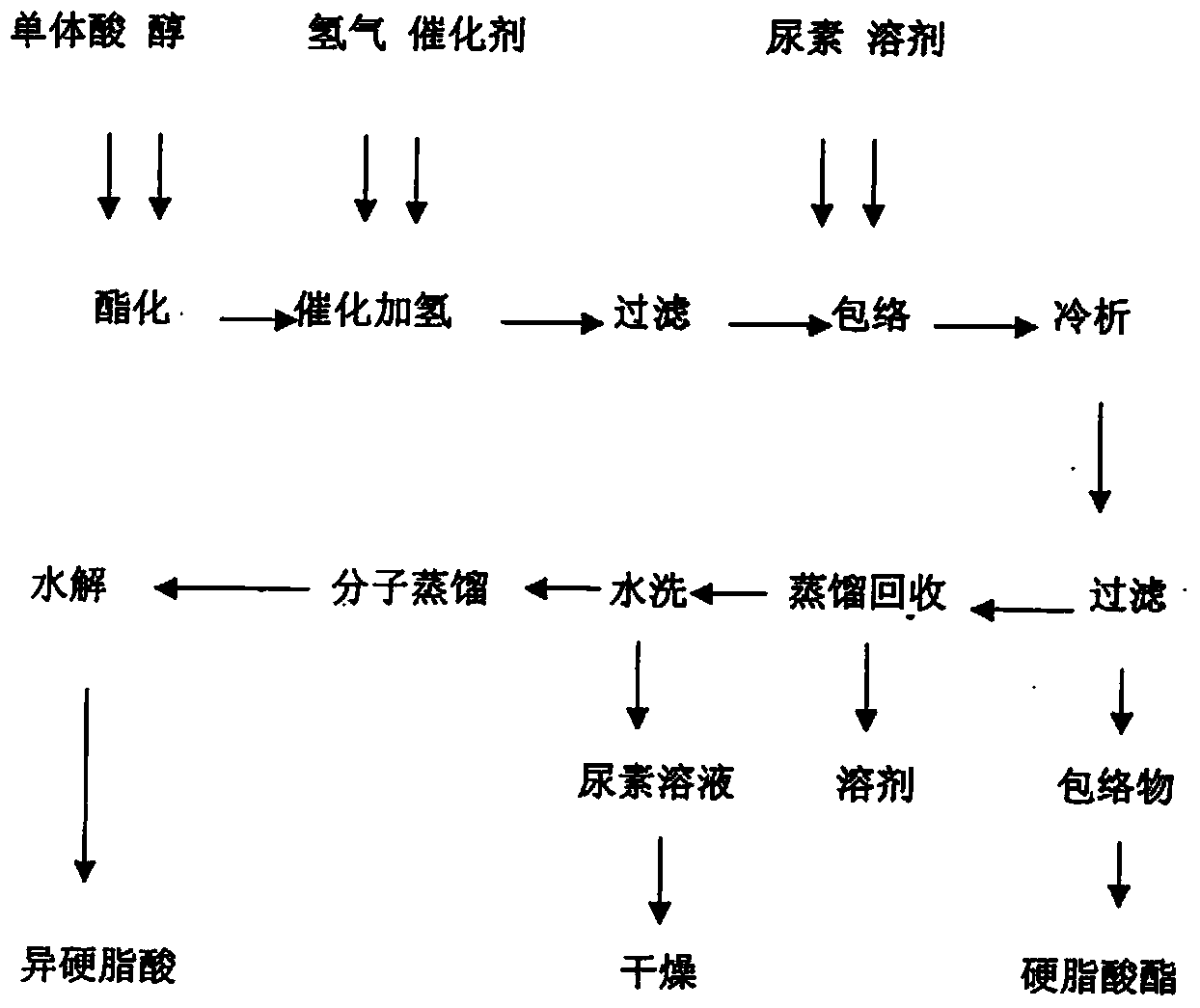

Method for preparing silkworm pupa oil for auxiliarily reducing blood lipid

InactiveCN107629862AIncrease alpha-linolenic acid contentHigh nutritional valueFatty-oils/fats refiningFatty-oils/fats productionWater bathsAlkaline protease

The invention discloses a method for preparing silkworm pupa oil for auxiliarily reducing blood lipid, wherein the method includes the steps: a) mixing a silkworm pupa powder and water according to the weight and volume ratio of (5-7):100 evenly, to obtain a silkworm pupa solution; b) adding the obtained silkworm pupa solution into immobilized alkaline protease EC 3.4.21.62, carrying out enzymolysis, inactivating enzymes for 5-7 min with boiling water bath, and allowing to stand for liquid separation, to obtain an upper-layer crude silkworm pupa oil; and c) carrying out degumming, deacidifyingand decoloring treatment on the obtained upper-layer crude silkworm pupa oil, to obtain the silkworm pupa oil. The specific immobilized alkaline protease EC 3.4.21.62 is adopted for enzymolysis; compared with traditional methods for extracting silkworm pupa oil, the method can significantly improve the alpha-linolenic acid content in the silkworm pupa oil, and has higher nutritional value of thesilkworm pupa oil (lower acid value, lower saponification value and higher iodine value), so that the prepared silkworm pupa oil is proved to have a significant effect for auxiliarily reducing blood lipid.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

A kind of preparation method of the oil hydrogenation nano-catalyst that catalytic activity improves

ActiveCN107262100BImprove wettabilityImprove permeabilityHeterogenous catalyst chemical elementsFatty-oils/fats refiningNano catalystPtru catalyst

The invention discloses a preparation method of an oil hydrogenation nano-catalyst for improving catalytic activity and belongs to the technical field of nano-catalysts. The preparation method of the oil hydrogenation nano-catalyst disclosed by the invention comprises the following steps: taking nano calcium carbonate as a carrier, enabling an alkaline precipitant to react with a metal salt of a catalytic activity component, and supporting the catalytic activity component onto a carrier. Moreover, a surfactant is added in the preparation process, and an adsorption behavior of reactive metals is influenced due to competitive adsorption between the surfactant and the activated metal ions during a precipitation reaction. Meanwhile, due to the wetting and spreading characteristics of the surfactant, the wetting and penetrating properties of the activated metal salt solution on the carrier are promoted, and the dispersion property of the catalytic activity component on the carrier is excellent, so that the activity of the prepared catalyst is improved.

Owner:JIANGNAN UNIV

A kind of preparation technology of ink cartridge

The invention discloses a preparation process of an ink cartridge and relates to the field of chemical processes. The preparation process comprises the steps of separating the ink cartridge, preparing a cleaning agent and preparing printing ink, wherein the preparation of the printing ink comprises the steps of adding 20% by weight of a colorless fluorescent agent into tea seed oil at the temperature of 30-50 DEG C, uniformly stirring and mixing, adding epoxy resin into a reaction kettle, filling oxygen of 1-2MPa into the reaction kettle, rapidly heating the reaction kettle to 300 DEG C while continuously stirring, reacting for 10min, not introducing the oxygen any more, adding Fischer-Tropsch wax and organic siloxane, scattering a pigment with particle size of 10-100nm into an epoxy resin molten solution in 1-3 times, mixing for 20-30min, reducing the temperature to be 80-100 DEG C, adding a dye, a colorless fluorescent agent solution, flaxseed oil, paraben and corn starch, uniformly mixing, adding a vitamin c saturated water solution and butyl alcohol and stirring at 1000r / min for 20min. According to the preparation process disclosed by the invention, the ink cartridge is divided into two parts, namely an ink cartridge box and a cleaning box, and after the printing ink is used up, the ink cartridge can be cleaned, so that the quality of the filled printing ink is ensured and the waste ink cartridge can be prevented from polluting an environment.

Owner:丹阳恒安化学科技研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com