Method for producing oil or fat

A manufacturing method and oil technology, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat separation, etc. It can solve the problems of unestablished and difficult to remove additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076]

[0077] Iodine value was determined using the A.O.C.S. test method (Official Method Cd 1-25). Specifically, 10 mL of cyclohexane was added and dissolved in 0.5 to 3 g of sample oil and fat, and then 25 mL of Wijs solution was added and left to stand in a dark place for 1 hour. Then, after adding 20 mL of 10 g / 100 mL potassium iodide solution and 100 mL of water to stop the reaction, titrate with 0.1 N sodium thiosulfate to obtain the amount of iodine added to fats and oils. The iodine value conversion method is based on the following formula.

[0078] Iodine value = (A-B) × F × 1.269 / C

[0079] A: In the above determination test, the amount of 0.1mol / L sodium thiosulfate standard solution used in the blank test without adding sample oil (ml)

[0080] B: the amount of 0.1mol / L sodium thiosulfate standard solution in the above-mentioned determination test (ml)

[0081] F: Correction coefficient of 0.1mol / L sodium thiosulfate (1.005 in this example)

[0082] C: Samp...

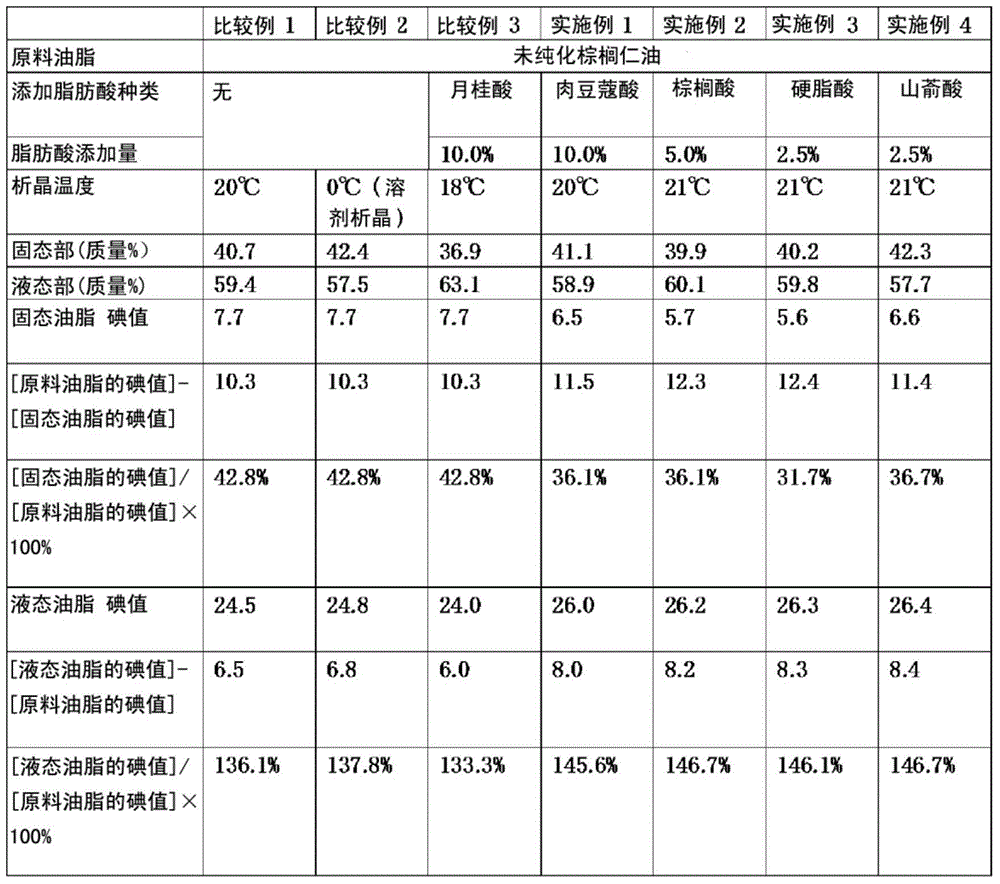

Embodiment 1

[0093] 450.0 g of the same palm kernel oil as in Comparative Example 1 was mixed with 50.0 g of myristic acid (manufactured by Wako Pure Chemical Industries, Ltd.), and heated at 60° C. for 1 hour in a constant temperature water bath at 60° C. to make the palm kernel oil and nutmeg The acid melts completely. The melted heating melt was put into a container made of polypropylene, and was left to stand in a constant temperature water bath at 20° C. for 12 hours to cool and solidify, thereby crystallizing the filter cake. Subsequent operations were performed in the same manner as in Comparative Example 1, and fatty acids were removed to obtain purified solid fats and oils and liquid fats and oils. The results are shown in Table 1.

Embodiment 2

[0095] 475.0 g of the same palm kernel oil as in Comparative Example 1 was mixed with 25.0 g of palmitic acid (manufactured by Wako Pure Chemical Industries, Ltd.), and heated at 60° C. for 1.5 hours in a constant temperature water bath at 60° C. to completely dissolve the palm kernel oil and palmitic acid. molten. The melted heating melt was put into a container made of polypropylene, and was left to stand in a constant temperature water bath at 21° C. for 12 hours to cool and solidify, thereby crystallizing the filter cake. Subsequent operations were performed in the same manner as in Comparative Example 1, and fatty acids were removed to obtain purified solid fats and oils and liquid fats and oils. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com