Method for preparing silkworm pupa oil for auxiliarily reducing blood lipid

A technology for assisting blood lipid lowering and silkworm chrysalis, applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of complicated operation, affecting the quality of oil products, and high operating temperature, achieving high nutritional value and improving α- The effect of linolenic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

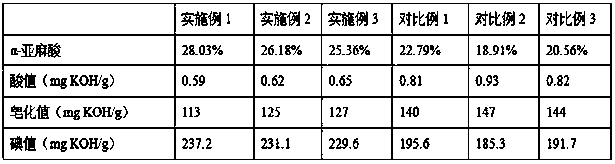

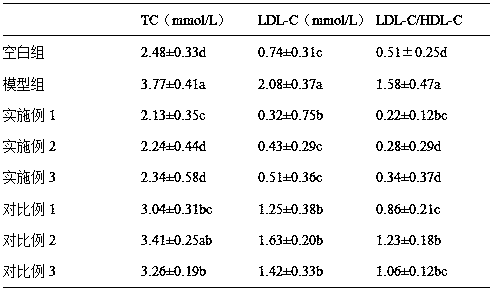

Embodiment 1

[0025] A method for preparing silkworm chrysalis oil for assisting blood fat reduction, comprising the following steps:

[0026] a) Mix the silkworm chrysalis powder and water evenly according to the weight volume ratio of 6:100 to obtain a silkworm chrysalis solution with a substrate concentration of 60 mg / mL;

[0027] b) Add immobilized alkaline protease (enzyme activity: 2250U / mL) to the obtained silkworm chrysalis solution for enzymolysis at pH 7.2 and enzymolysis temperature of 48°C for 60 minutes, then inactivate the enzyme in a boiling water bath for 6 minutes, and stand to separate the liquid to obtain Crude silkworm chrysalis oil in the upper layer; wherein, the preparation method of the immobilized alkaline protease EC 3.4.21.62 comprises the following steps: adding 1.351 g FeCl to 25 mL deionized water at 25 °C 3 •6H 2 O, 0.6852g FeSO 4 •7H 2 O, then add excess ammonia water, the precipitate is obtained by centrifugation and washed with deionized water until the ...

Embodiment 2

[0030] A method for preparing silkworm chrysalis oil for assisting blood fat reduction, comprising the following steps:

[0031] a) Mix silkworm chrysalis powder and water evenly according to the weight volume ratio of 5:100 to obtain a silkworm chrysalis solution with a substrate concentration of 50 mg / mL;

[0032] b) Add immobilized alkaline protease EC 3.4.21.62 (enzyme activity: 2500 U / mL) to the obtained silkworm chrysalis solution for enzymolysis at pH 7.0 and 45°C for 70 minutes, then inactivate the enzyme in a boiling water bath for 7 minutes, Stand still and separate the liquid to obtain the crude silkworm chrysalis oil in the upper layer; wherein, the preparation method of the immobilized alkaline protease EC 3.4.21.62 comprises the following steps: at 25°C, add 1.351 g FeCl to 25 mL deionized water 3 •6H 2 O, 0.6852g FeSO 4 •7H 2 O, then add excess ammonia water, the precipitate is obtained by centrifugation and washed with deionized water until the pH is 7.0 to ...

Embodiment 3

[0035] A method for preparing silkworm chrysalis oil for assisting blood fat reduction, comprising the following steps:

[0036] a) Mix silkworm chrysalis powder and water evenly according to the weight volume ratio of 7:100 to obtain a silkworm chrysalis solution with a substrate concentration of 70 mg / mL;

[0037] b) Add immobilized alkaline protease EC 3.4.21.62 (enzyme activity: 2000U / mL) to the obtained silkworm chrysalis solution for enzymolysis at pH 7.5 and enzymolysis temperature of 50°C for 50 minutes, inactivate the enzyme in a boiling water bath for 5 minutes, and let stand Liquid separation to obtain the crude silkworm chrysalis oil in the upper layer; wherein, the preparation method of the immobilized alkaline protease EC 3.4.21.62 comprises the following steps: at 25°C, 1.351 g FeCl is added to 25 mL deionized water 3 •6H 2 O, 0.6852g FeSO 4 •7H 2 O, then add excess ammonia water, the precipitate is obtained by centrifugation and washed with deionized water u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com