Cultivation material for improving black fungus nutrition quality and application of cultivation material

A cultivation material, black fungus technology, applied in the application, cultivation, calcareous fertilizer and other directions, can solve problems such as waste of resources, and achieve the effects of low cost, huge market development space, and easy replication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

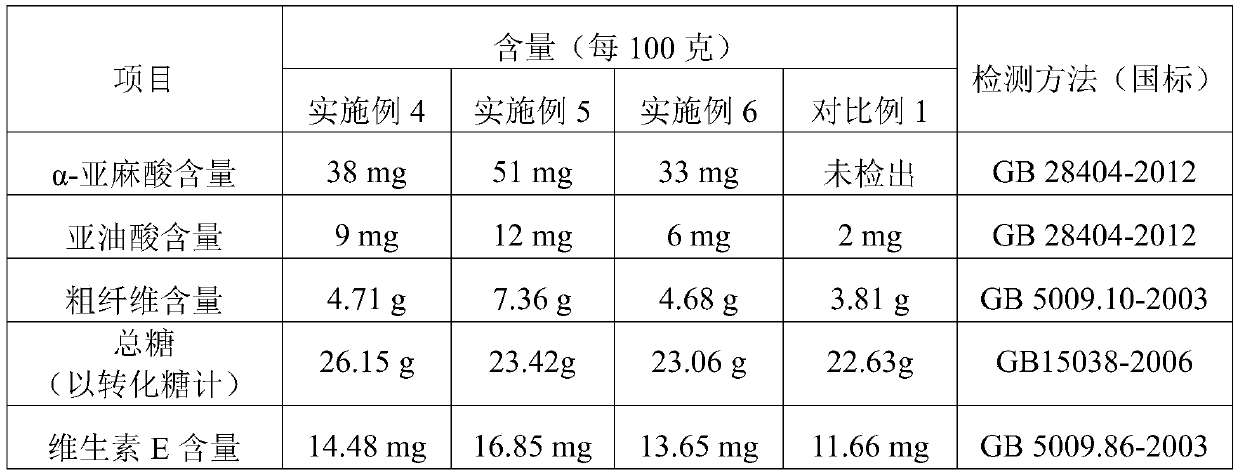

Examples

Embodiment 1

[0020] Embodiment 1. black fungus cultivation material.

[0021] The black fungus cultivation material described in this example is prepared by the following method: 73 parts by weight of corncobs, 6 parts by weight of perilla stalks, 2 parts by weight of sucrose, 5 parts by weight of bran, 1 part by weight of gypsum and 20 parts by weight of cottonseed hulls , crushed and passed through a 2-mesh sieve, and then mixed, and the mixture was mixed with water at a ratio of 1 gram: (1.3-1.4) milliliters of solid to liquid, which was black fungus cultivation material.

Embodiment 2

[0022] Embodiment 2. black fungus cultivation material.

[0023] The black fungus cultivation material described in this example is prepared by the following method: 80 parts by weight of corncobs, 16 parts by weight of perilla stalks, 5 parts by weight of sucrose, 7 parts by weight of bran, 3 parts by weight of gypsum and 25 parts by weight of cottonseed hulls , crushed and passed through a 3-mesh sieve, and then mixed, and the mixture was mixed with water at a ratio of 1 gram: (1.3-1.4) milliliters of material to liquid, which was black fungus cultivation material.

Embodiment 3

[0024] Embodiment 3. black fungus cultivation material.

[0025] The black fungus cultivation material described in this example is prepared by the following method: 60 parts by weight of corncobs, 5 parts by weight of perilla stalks, 2 parts by weight of sucrose, 4 parts by weight of bran, 1 part by weight of gypsum and 18 parts by weight of cottonseed hulls , crushed and passed through a 3-mesh sieve, then mixed, and the mixture was mixed with water according to the ratio of 1 g: 1.4 ml of material to liquid, which was the black fungus cultivation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com