Oat and linolenic acid composite beverage and preparation method thereof

A technology of linolenic acid and oats, which is applied in other beverage processing fields, and can solve problems such as the precipitation of additives, the inability to fully utilize oats, and complex formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

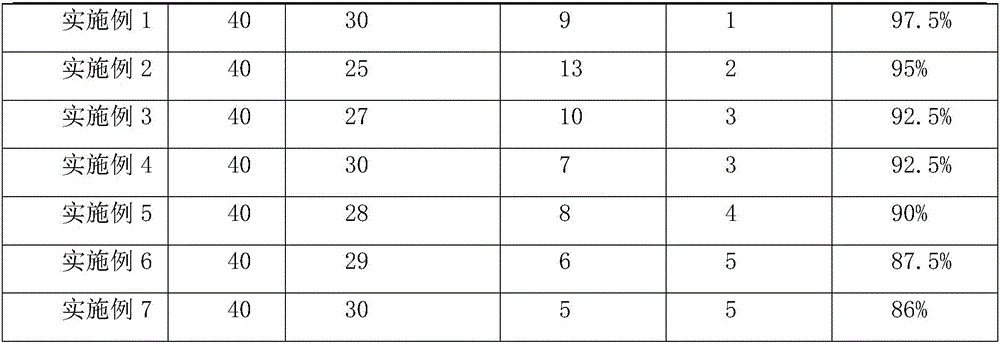

Examples

Embodiment 1

[0065] An oatmeal compound linolenic acid beverage is prepared from raw materials comprising the following mass percentages:

[0066] Oat 3.8%, linseed oil 2%, maltose 2.4%, fructooligosaccharide 0.4%, xylitol 1%, sucrose 2%, coconut milk 4%, compound emulsion stabilizer 0.2%, food flavor 0.005%, sodium ascorbate 0.5 %, the rest is soft water;

[0067] The compound emulsion stabilizer comprises raw materials in the following weight ratio: sucrose fatty acid ester: sodium tripolyphosphate: xanthan gum: sodium caseinate: β-cyclodextrin: Tween 60=2:3:2:4 :0.5:2;

[0068] The edible essence includes ethyl maltol;

[0069] The mass percentage of said ethyl maltol in said edible essence is: 35%;

[0070] A preparation method of oat compound linolenic acid drink, comprising the steps of:

[0071] Oatmeal is prepared oat concentrate, comprises the steps:

[0072] After the oats in the formula amount are pulverized, mix the oats with soft water at 50°C according to the weight rati...

Embodiment 2

[0093] An oatmeal compound linolenic acid beverage is prepared from raw materials comprising the following mass percentages:

[0094] Oat 1%, linseed oil 1%, maltose 2%, fructooligosaccharide 0.2%, xylitol 1%, starch syrup 4%, coconut milk 2%, compound emulsification stabilizer 0.1%, food flavor 0.01%, sodium ascorbate 1%, the rest is soft water;

[0095] The composite emulsion stabilizer comprises raw materials in the following weight ratio: sucrose fatty acid ester: sodium tripolyphosphate: xanthan gum: sodium caseinate: β-cyclodextrin: Tween 60=2:4:3:4 :0.5:1;

[0096] The edible essence includes ethyl maltol;

[0097] The mass percentage of the ethyl maltol in the edible essence is: 40%;

[0098] A preparation method of oat compound linolenic acid drink, comprising the steps of:

[0099] Oatmeal is prepared oat concentrate, comprises the steps:

[0100] After the oatmeal is pulverized, according to the weight ratio of oatmeal: soft water = 1:10, mix the oatmeal with s...

Embodiment 3

[0121] An oatmeal compound linolenic acid beverage is prepared from raw materials comprising the following mass percentages:

[0122] Oat 6%, linseed oil 8%, maltose 3%, fructooligosaccharide 0.6%, xylitol 3%, sucrose 1%, coconut milk 6%, compound emulsification stabilizer 0.3%, food flavor 0.005%, sodium ascorbate 0.1 %, the rest is soft water;

[0123] The composite emulsion stabilizer comprises raw materials in the following weight ratio: sucrose fatty acid ester: sodium tripolyphosphate: xanthan gum: sodium caseinate: β-cyclodextrin: Tween 60=2:4:3:4 :0.5:1;

[0124] The edible essence includes ethyl maltol;

[0125] The mass percentage of said ethyl maltol in said edible essence is: 30%;

[0126] A preparation method of oat compound linolenic acid drink, comprising the steps of:

[0127] Oatmeal is prepared oat concentrate, comprises the steps:

[0128] After the oatmeal is pulverized, mix the oatmeal with soft water at 55°C according to the weight ratio of oatmeal: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com