Preparation method of biodegradable drawing oil

A biodegradable and wire drawing oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of environmental pollution, difficult biodegradation, poor oxidation stability, etc., achieve wide application prospects, reduce the content of double bonds, and reduce oxidation stability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

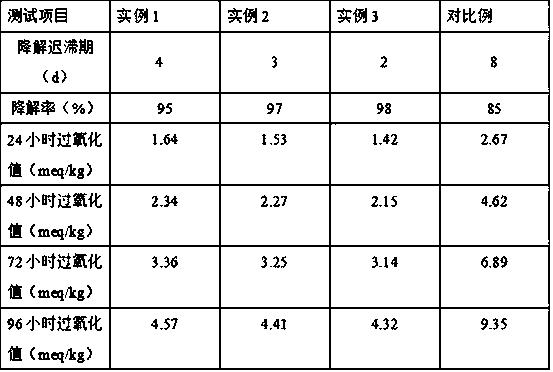

Examples

example 1

[0022] Put lard and palm oil in a mass ratio of 1:2 in a four-necked flask equipped with a stirrer, a condenser and a thermometer, and stir for 6 minutes at a temperature of 55°C to obtain a saponified liquid, which is then poured into a four-necked flask Add 5% methanol solution with 3% saponification solution mass fraction and 15% sodium hydroxide solution with 15% saponification solution mass fraction, continue the heat preservation reaction for 45 minutes, leave to separate layers, remove the lower glycerin, and obtain the upper layer liquid, and successively wash the supernatant liquid with a mass fraction of 10% hydrochloric acid solution and deionized water, adjust the pH of the supernatant to neutrality, continue vacuum distillation to obtain mixed oil fatty acid methyl ester, weigh 35g mixed oil fatty acid methyl ester Put the ester in a beaker, stir for 9 minutes at a temperature of 40°C, then add 20g of trimethylolpropane to the beaker, mix and stir for 16min at a pr...

example 2

[0024]Put lard and palm oil in a mass ratio of 1:2 in a four-necked flask equipped with a stirrer, a condenser and a thermometer, and stir for 7 minutes at a temperature of 60°C to obtain a saponified liquid, which is then poured into a four-necked flask Add 5% methanol solution with 3% saponification solution mass fraction and 15% sodium hydroxide solution with 15% saponification solution mass fraction, continue the heat preservation reaction for 50min, leave to separate layers, remove the lower layer of glycerin, and obtain the upper layer solution, and successively wash the supernatant with 10% hydrochloric acid solution and deionized water to adjust the pH of the supernatant to neutral, and continue vacuum distillation to obtain mixed oil fatty acid methyl ester, and take 40g mixed oil fatty acid methyl ester Put the ester in a beaker, stir at 50°C for 10min, then add 22g of trimethylolpropane to the beaker, mix and stir for 18min at a pressure of 0.4MPa, heat up to 85°C, t...

example 3

[0026] Mix lard and palm oil in a mass ratio of 1:2 and place them in a four-necked flask equipped with a stirrer, a condenser and a thermometer, and stir for 8 minutes at a temperature of 65°C to obtain a saponified liquid, which is then poured into the four-necked flask Add 5% methanol solution with a mass fraction of 3% of the saponification solution and 15% sodium hydroxide solution with a mass fraction of 1% of the saponification solution, continue the heat preservation reaction for 60 minutes, leave to separate layers, remove the lower layer of glycerin, and obtain the upper layer solution, and successively wash the supernatant with 10% hydrochloric acid solution and deionized water to adjust the pH of the supernatant to neutrality, continue vacuum distillation to obtain mixed oil fatty acid methyl ester, weigh 45g mixed oil fatty acid methyl ester Put the ester in a beaker, stir at 60°C for 11min, then add 24g of trimethylolpropane to the beaker, mix and stir for 20min a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com