Method for depositing hydroxyapatite on metal surface and metal implant

A hydroxyapatite and metal surface technology, applied in the field of medical devices, can solve the problems of low crystallinity of HA particles, high content of soluble calcium phosphate, poor surface binding force, etc., to suppress the generation of hydrogen, improve the purity and crystallization of HA Degree, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The method for depositing hydroxyapatite on the metal surface described in this embodiment is as follows:

[0072] First, a smooth titanium sheet with a side length of 25 mm and a thickness of 2 mm is provided as a metal substrate.

[0073]Next clean the titanium sheet. Pure water, isopropanol, and pure water were used as cleaning agents in sequence, and ultrasonic vibration was used to clean the titanium sheet, and the cleaning time was 15 minutes each time. Then, the titanium sheet was pickled in a mixed solution containing 20% nitric acid and 5% hydrofluoric acid, and the pickling time was 20s. Finally, rinse the titanium piece in pure water for 3-4 times. Unless otherwise specified herein, "%" refers to mass percentage.

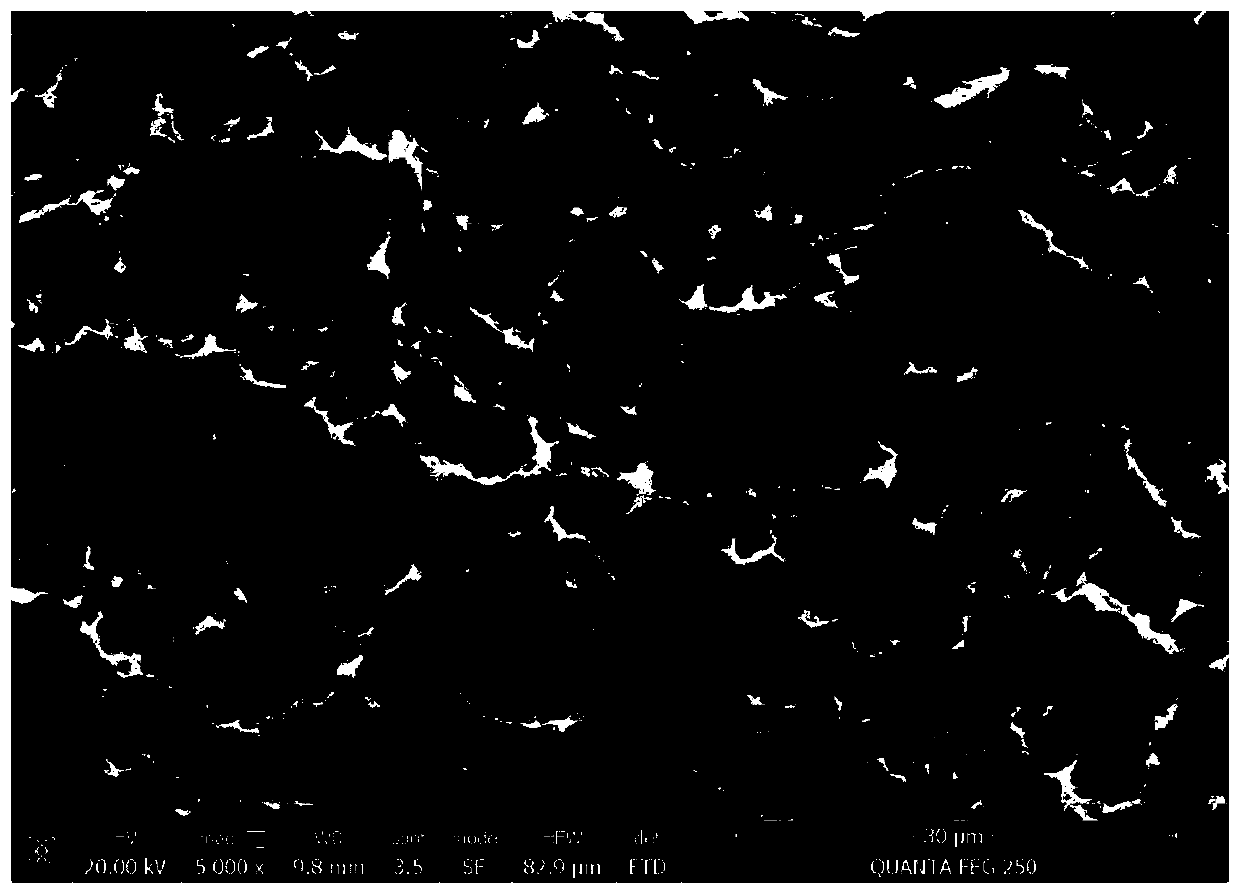

[0074] Next, a rough structure is formed on the surface of the titanium sheet. The cleaned titanium sheet was placed in a mixed acid solution containing 24% sulfuric acid and 9% hydrochloric acid, reacted in a water bath for 1 hour at 70° C.,...

Embodiment 2

[0082] The method for depositing hydroxyapatite on the metal surface described in this embodiment is as follows.

[0083] First, a smooth titanium sheet with a side length of 25 mm and a thickness of 2 mm is provided as a metal substrate.

[0084] Next clean the titanium sheet. Pure water, isopropanol, and pure water were used as cleaning agents in sequence, and ultrasonic vibration was used to clean the titanium sheet, and the cleaning time was 15 minutes each time. Then, the titanium sheet was pickled in a mixed solution containing 40% nitric acid and 3% hydrofluoric acid, and the pickling time was 20s. Finally, rinse the titanium piece in pure water for 3-4 times.

[0085] Next, a rough structure is formed on the surface of the titanium sheet.

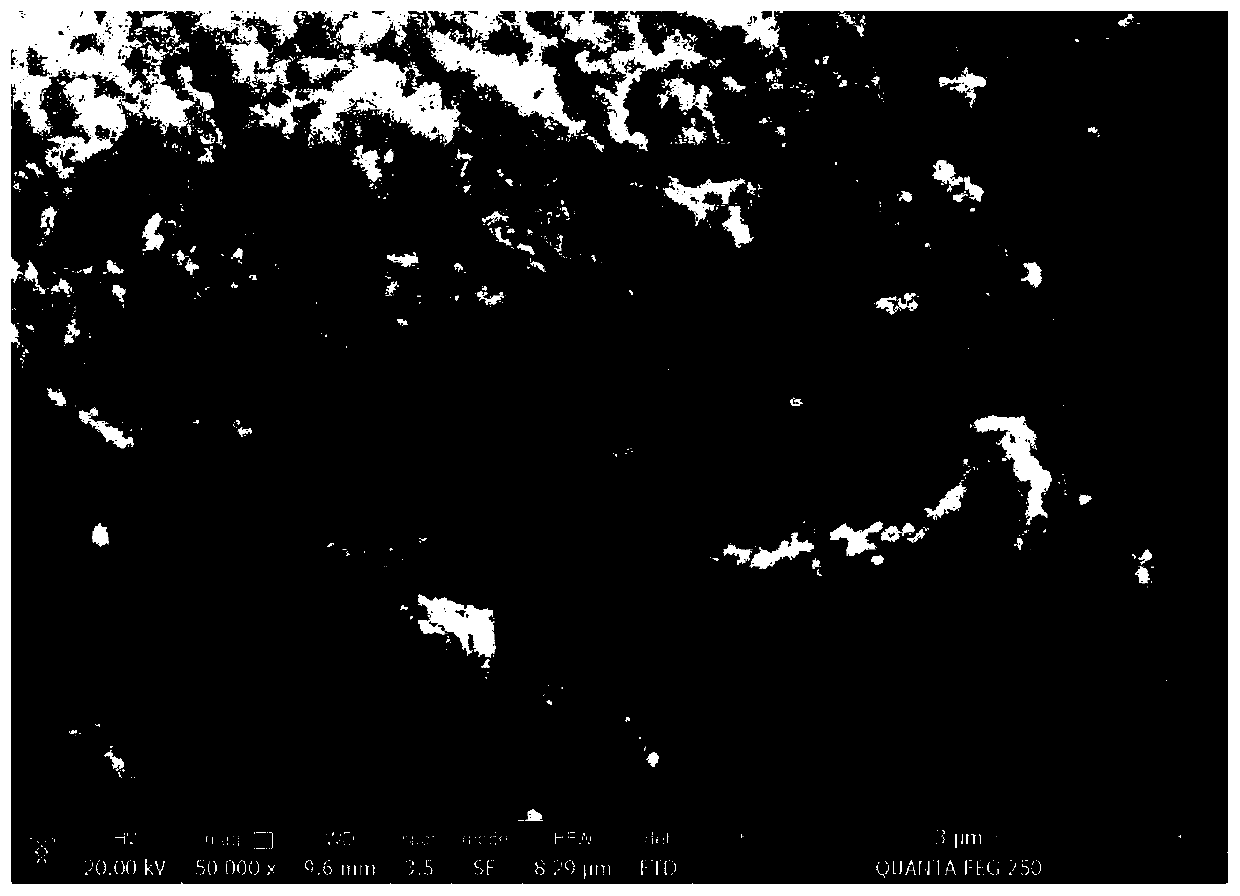

[0086] In this embodiment, a micron-scale rough structure and a nano-scale rough structure are formed on the surface of the titanium sheet, and the specific operations are as follows:

[0087] Step 1): Place the cleaned titanium...

Embodiment 3

[0096] The method for depositing hydroxyapatite on the metal surface described in this embodiment is as follows.

[0097] First, a smooth titanium sheet with a side length of 25 mm and a thickness of 2 mm is provided as a metal substrate.

[0098] Next clean the titanium sheet. Pure water, isopropanol, and pure water were used as cleaning agents in sequence, and ultrasonic vibration was used to clean the titanium sheet, and the cleaning time was 15 minutes each time. Then, the titanium sheet was pickled in a mixed solution containing 30% nitric acid and 5% hydrofluoric acid, and the pickling time was 20s. Finally, rinse the titanium piece in pure water for 3-4 times.

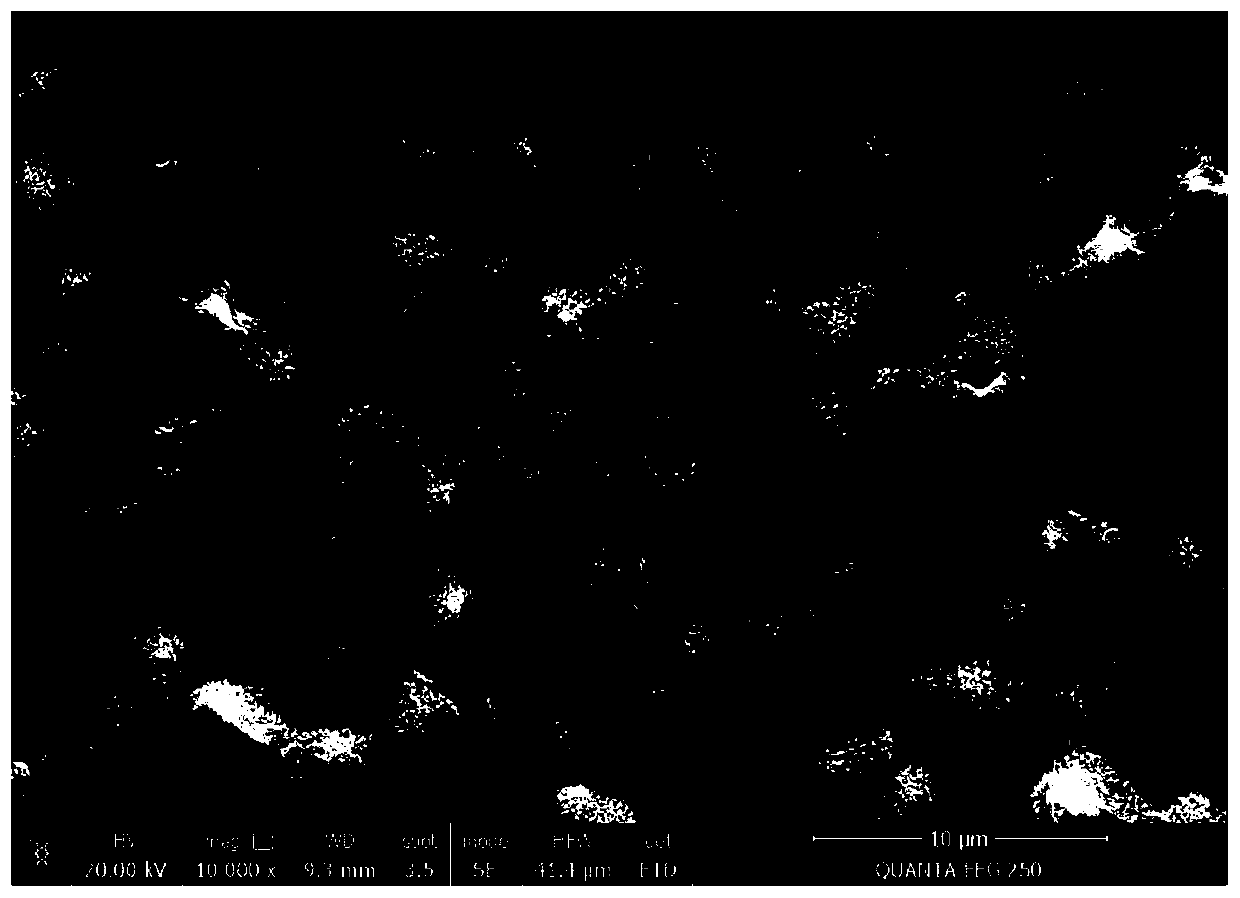

[0099] Next, a rough structure is formed on the surface of the titanium sheet. The specific operation is as follows: in the fluorine-containing acid solution, the cleaned titanium sheet is used as the anode, and the graphite electrode sheet is used as the cathode, and the reaction is performed at a DC voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com