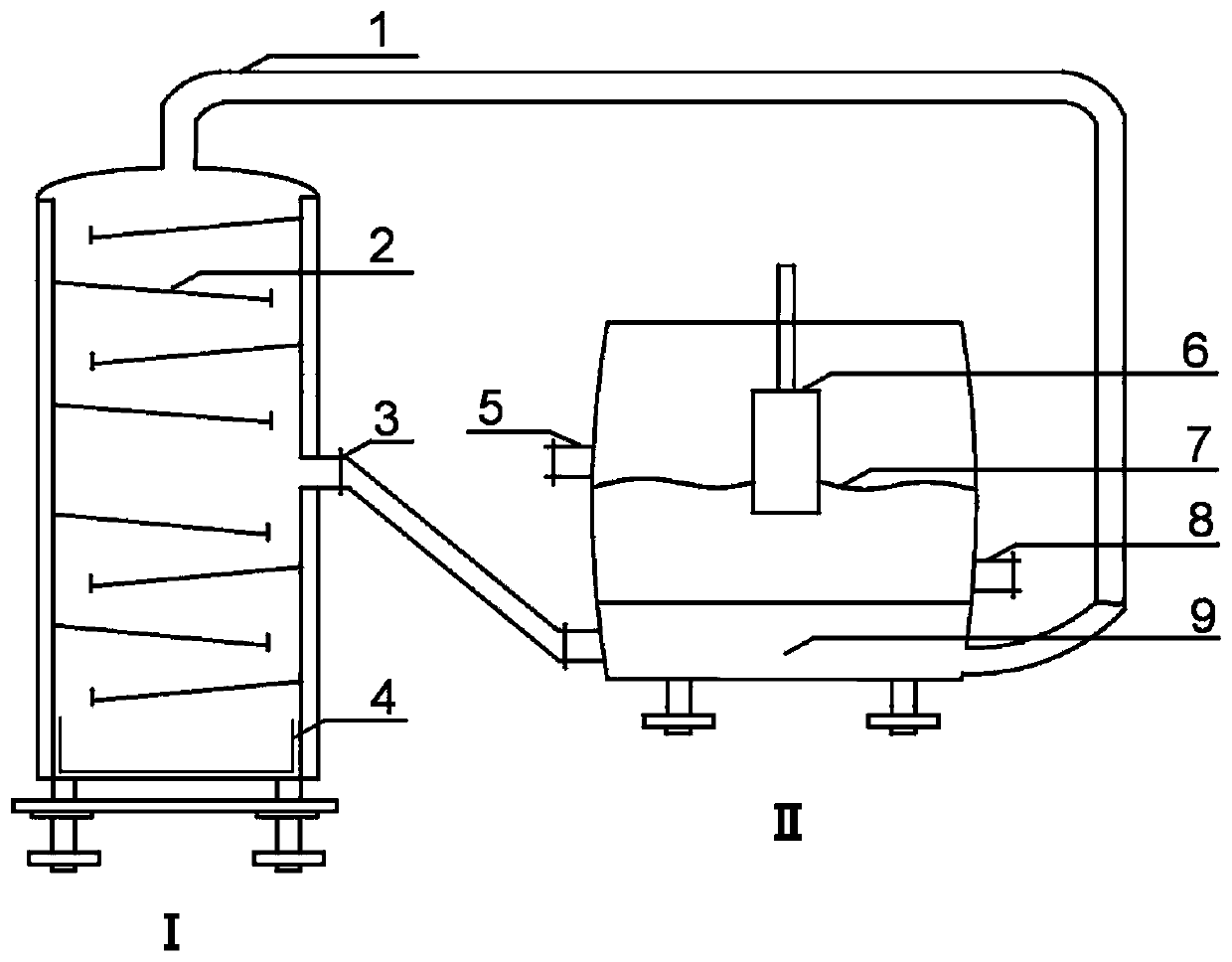

Method and device for continuously preparing high-purity titanium through oxide fusion electrolysis-vacuum rectification

A technology of molten electrolysis and vacuum distillation, which is applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high energy consumption and low production efficiency of electrolysis, and achieve the effects of wide sources, low production cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: adopt tin as cathode, iron-chromium alloy as anode, titanium-containing oxide slag (25.35wt% CaO, 14.83wt% Al 2 o 3 , 7.84wt% MgO, 23.41wt% SiO 2 and 28.57wt% TiO 2 ) is the electrolyte. Raise the temperature to 1550°C, pre-melt for 3 hours, then lower the anode into the electrolyte, and simultaneously energize the anode and cathode to start constant current electrolysis with a current density of 3A cm -2 ; During the electrolysis process, argon is passed through the electrolysis furnace for protection.

[0025] Step 2: Monitor the titanium ion activity in the titanium-containing oxide slag and the tin-titanium alloy. When the titanium ion activity in the titanium-containing oxide slag is less than 8%, open the slag outlet to discharge the slag, and open the slag delivery port to send the slag at the same time. Ensure that the titanium ion activity in the titanium-containing oxide slag is between 6 and 80%; at the same time, when the titanium ion activity in...

Embodiment 2

[0028] Step 1: Using antimony as the cathode, graphite as the anode, titanium oxide slag (19.54wt% CaO, 21.46wt% Al 2 o 3 , 4.21wt% MgO, 11.09wt% SiO 2 ,16.32wt%TiO 2 and 27.38 wt% CaF 2 ) is the electrolyte. Raise the temperature to 1400°C, pre-melt for 2 hours, then lower the anode into the electrolyte, and simultaneously energize the anode and cathode to start constant current electrolysis with a current density of 6A cm -2 ; During the electrolysis process, argon is passed through the electrolysis furnace for protection.

[0029] Step 2: Monitor the titanium ion activity in the titanium-containing oxide slag and the antimony-titanium alloy cathode. When the titanium ion activity in the titanium-containing oxide slag is less than 8%, open the slag outlet to discharge the slag, and simultaneously open the slag delivery port to send the slag. Always ensure that the titanium ion activity in the titanium-containing oxide slag is between 6 and 80%; at the same time, when th...

Embodiment 3

[0032] Step 1: adopt lead-bismuth alloy as cathode, iron-chromium alloy as anode, titanium oxide slag (32.11wt% CaO, 22.34wt% Al 2 o3 , 13.67wt% MgO, 6.21wt% SiO 2 and 25.67wt% TiO 2 ) is the electrolyte. Raise the temperature to 1500°C, perform pre-melting for 1 hour, then lower the anode into the electrolyte, and simultaneously energize the anode and cathode to start electrolysis at a constant voltage of 5V; during the electrolysis process, helium is passed through the electrolysis furnace for protection.

[0033] Step 2: Monitor the titanium ion activity in the titanium-containing oxide slag and lead-bismuth-titanium alloy cathode. When the titanium ion activity in the titanium-containing oxide slag is less than 8%, open the slag outlet for slag discharge, and open the slag delivery port to send slag at the same time , always ensure that the titanium ion activity in the titanium-containing oxide slag is between 6 and 80%; at the same time, when the titanium ion activity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com