Method for preparing high-quality fine lacquer wax product

A high-quality, lacquered wax technology, applied in the recovery/refining of fatty substances, recovery of fatty substances, recycling technology, etc., can solve problems such as low melting point and easy rancidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation of embodiment 1 high-quality lacquer wax fine product

[0059] The first step: pretreatment of raw materials

[0060] Before use, the lacquer seeds are dried by microwave, the microwave power is 100-800W, preferably 200-400W, and the microwave irradiation is 30-300s, preferably 60-200s; the lacquer seeds are crushed with a blade crusher or a mill, and passed through a sieve of more than 20 mesh , remove the upper seed core, and sieve out the pulp part of the lacquer seeds, wherein the water content is lower than 6%, and the oil content is higher than 45%;

[0061] The second step: the preparation of crude lacquer wax

[0062] The lacquer seed powder that adopts non-polar solvent leaching drying, non-polar solvent is sherwood oil (60~120 ℃), No. 6 solvent naphtha, one in ether, normal hexane, pentane etc., preferably sherwood oil (60 ~120℃), No. 6 solvent oil and n-hexane. The volume ratio of the mass of the lacquer pulp part to the extraction solvent ...

Embodiment 2

[0077] Step 1: Preparation of Crude Lacquer Wax

[0078] Put 500g of lacquer seeds into a 400W microwave oven and irradiate them with microwaves for 180s, cool down, then irradiate them with microwaves for 30s, cool them down, crush the lacquer seeds with a blade crusher or mill, and remove the upper layer of seeds through a sieve above 20 meshes. Sieve out the fruit powder of lacquer seeds, wherein the water content is lower than 6%, and the oil content is higher than 45%.

[0079] Using petroleum ether as a solvent, the volume ratio of lacquer seed fruit powder and extraction solvent is 1:20g / ml, at a temperature of 80°C, extract for 2 hours, extract twice, filter and combine the extracts, vacuum concentrate at 60°C, and concentrate The mixture was cooled to room temperature to obtain crude lacquer wax with a yield of 96%;

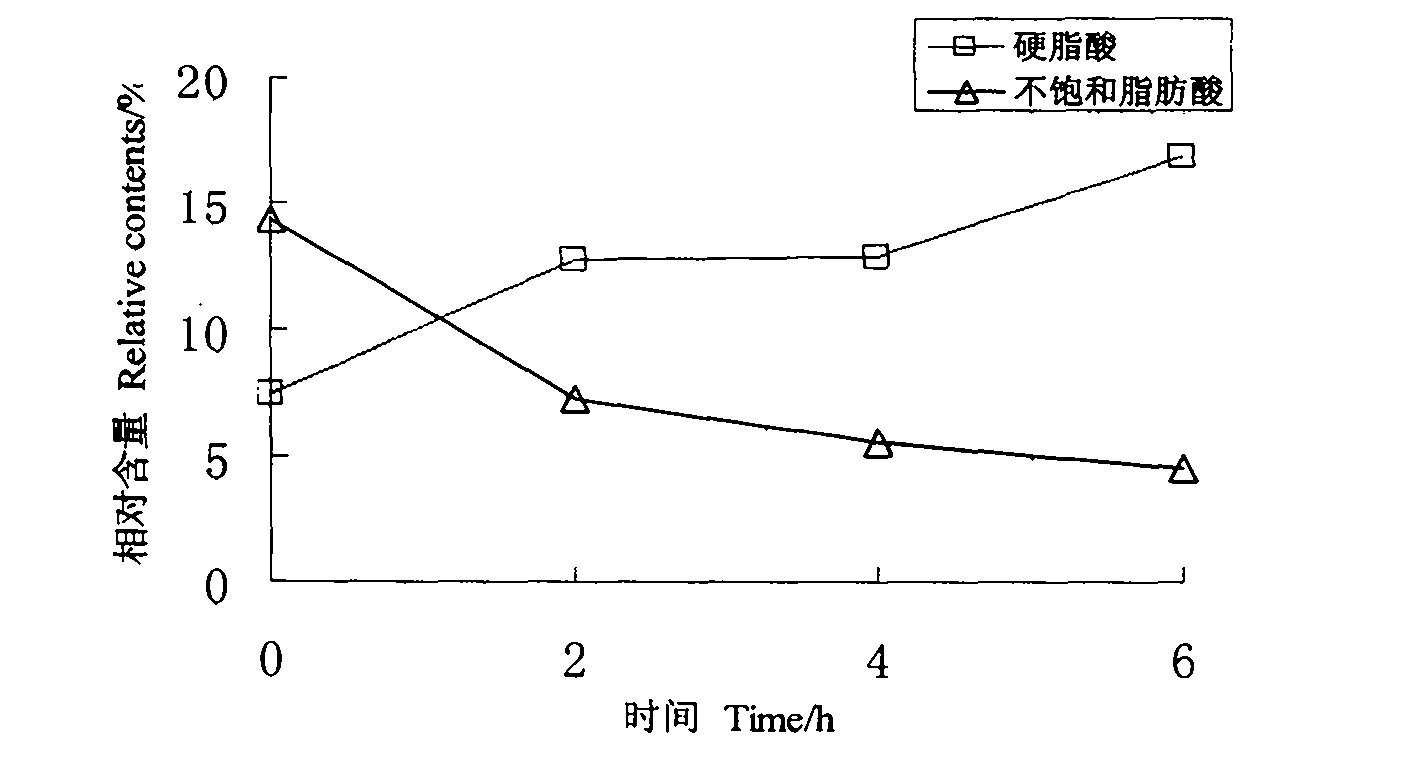

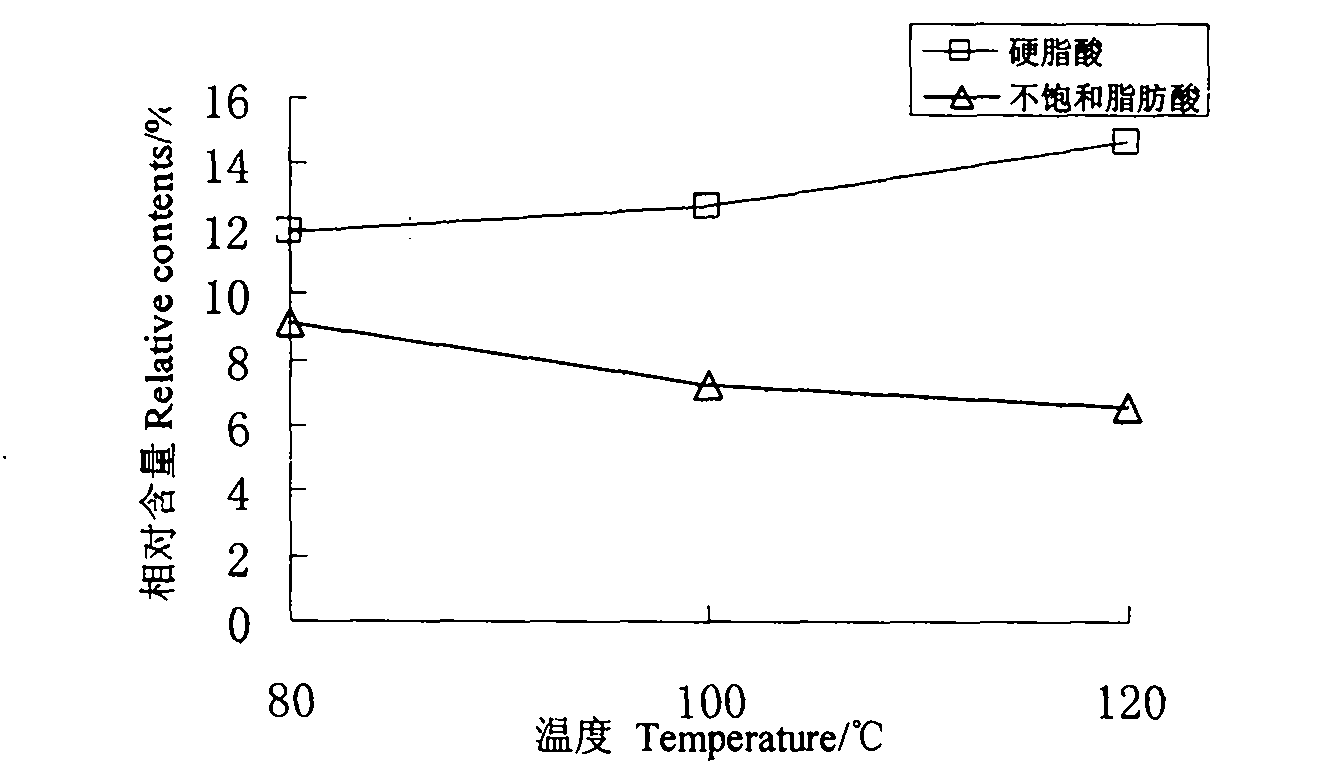

[0080] The second step: hydrogenation process of lacquer wax

[0081] Put the crude lacquer wax into a high-temperature and high-pressure reaction ket...

Embodiment 3

[0087] Step 1: Preparation of Crude Lacquer Wax

[0088] Dry the lacquer seeds with microwaves before use, crush the lacquer seeds with a blade crusher or a mill, and pass through a 40-mesh sieve. The dust is the pulp of the lacquer seeds. The volume ratio of the mass of the seed pulp to the extraction solvent is 1:15g / ml, the ultrasonic extraction power is 400W, the extraction temperature is 30°C, and the extraction is performed for 20 minutes; extraction is performed twice, and the extracts are combined after filtration and concentrated in a vacuum at 60°C. The concentrate was cooled to room temperature to obtain crude lacquer wax with an extraction rate of 98%;

[0089] The second step: hydrogenation process of lacquer wax

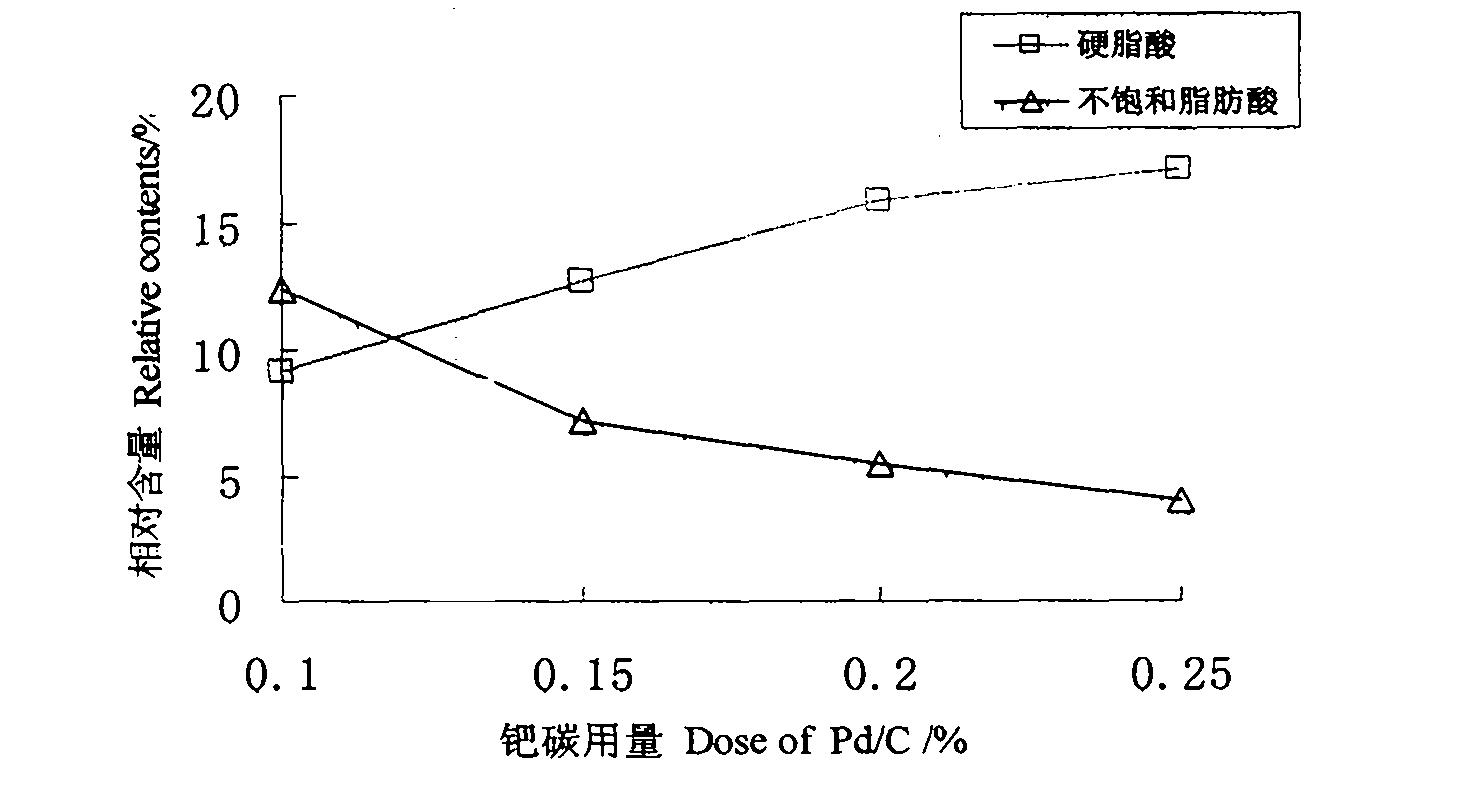

[0090] Put the crude lacquer wax into a high-temperature and high-pressure reactor, and add 0.3% palladium-carbon catalyst with a loading capacity of 0.5%, stir and heat up to make it fully mixed, the stirring speed is 200rpm, and the temperature range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com