Airplane skin external surface cleaning compound

A technology for aircraft skin and outer surface, applied in the directions of surface active detergent composition, detergent compounding agent, detergent composition, etc., can solve the problems of high cost, time-consuming and laborious, long cleaning time, etc., and achieve a reasonable ratio , high efficiency and excellent wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment is a cleaning agent for the outer surface of an aircraft skin, which is composed of a surfactant, a chelating agent, a corrosion inhibitor, an inorganic base and a solvent.

[0025] The surfactant includes sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether; wherein the fatty alcohol polyoxyethylene ether is AEO-7 and AEO-10. Described chelating agent is sodium edetate. The corrosion inhibitor is hexamethylenetetramine. Described inorganic base is sodium carbonate and sodium silicate. Described solvent is deionized water.

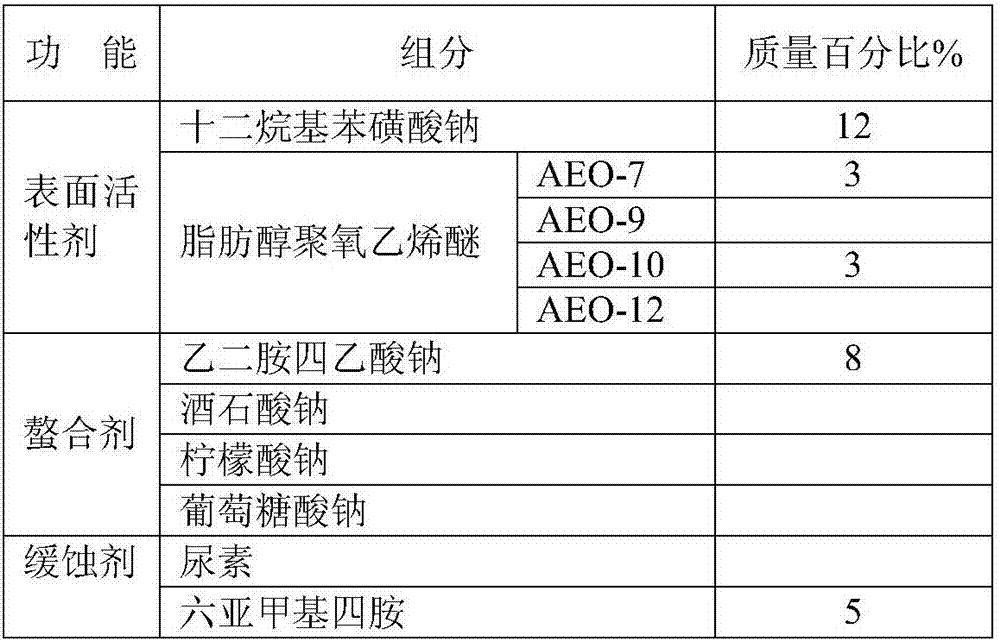

[0026] The mass percent of each component of this embodiment is shown in Table 1

[0027] The mass percent of each component of table 1 embodiment 1

[0028]

[0029]

[0030] When preparing, add the required amount of sodium dodecylbenzenesulfonate, AEO-7, AEO-12, sodium edetate, hexamethylenetetramine, sodium carbonate, and sodium silicate to the solvent In ionized water, stir until dissolved to make a ...

Embodiment 2

[0032] This embodiment is a cleaning agent for the outer surface of an aircraft skin, which is composed of a surfactant, a chelating agent, a corrosion inhibitor, an inorganic base and a solvent.

[0033] The surfactant includes sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether; wherein the fatty alcohol polyoxyethylene ether is AEO-7 and AEO-9. Described chelating agent is sodium citrate. The corrosion inhibitor is thiourea. Described inorganic base is sodium carbonate and sodium metasilicate. Described solvent is deionized water.

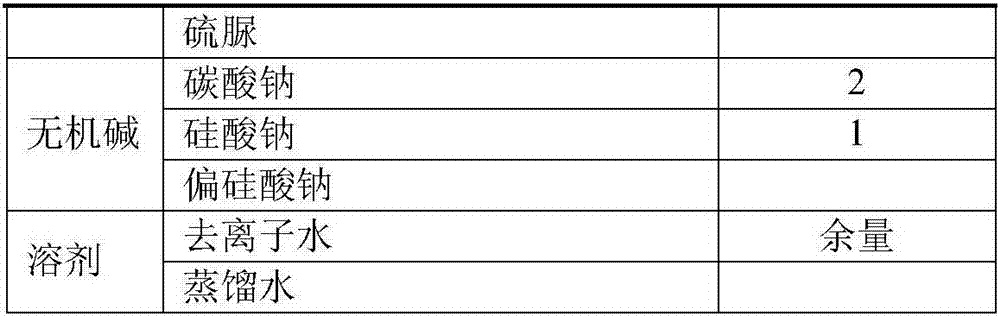

[0034] The mass percent of each component of this embodiment is shown in Table 2

[0035] The mass percent of each component of table 2 embodiment 2

[0036]

[0037] Preparation method: Add the required amount of sodium dodecylbenzenesulfonate, AEO-7, AEO-9, sodium citrate, thiourea, sodium carbonate, and sodium metasilicate into deionized water as the solvent, and stir until dissolved , made of aircraft skin outer su...

Embodiment 3

[0039] This embodiment is a cleaning agent for the outer surface of an aircraft skin, which is composed of a surfactant, a chelating agent, a corrosion inhibitor, an inorganic base and a solvent.

[0040] The surfactant includes sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether; wherein the fatty alcohol polyoxyethylene ether is AEO-7 and AEO-10. Described chelating agent is sodium gluconate. The corrosion inhibitor is urea. Described inorganic base is sodium carbonate and sodium silicate. Described solvent is distilled water.

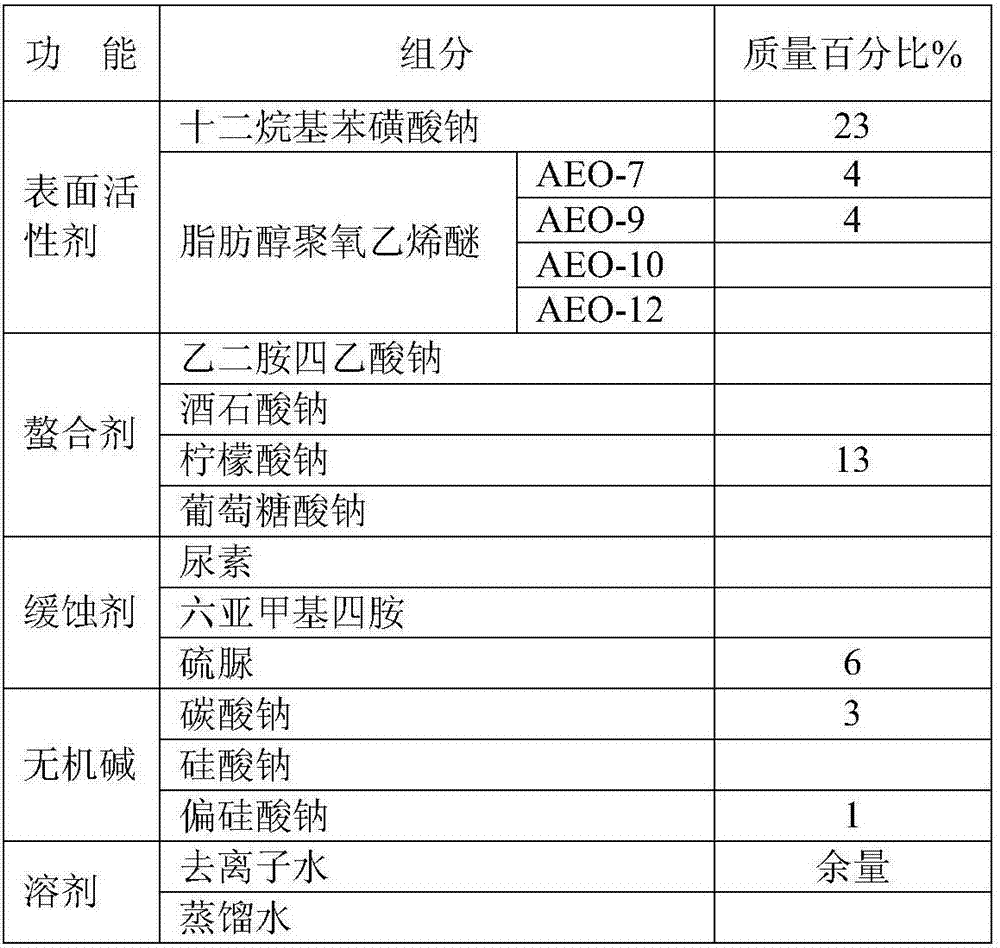

[0041] The mass percent of each component of this embodiment is shown in Table 3

[0042] The mass percent of each component of table 3 embodiment 3

[0043]

[0044] Preparation method: add the required amount of sodium dodecylbenzene sulfonate, AEO-7, AEO-10, sodium gluconate, urea, sodium carbonate, and sodium silicate into the distilled water of the solvent, stir until dissolved, and prepare Aircraft skin outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com