Adhesive agent and adhesive sheet produced using same

A technology of adhesives and adhesive sheets, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as air bubbles at the attachment interface, different dimensional change rates, light leakage, etc., and achieve excellent stress relaxation, Excellent re-peelability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

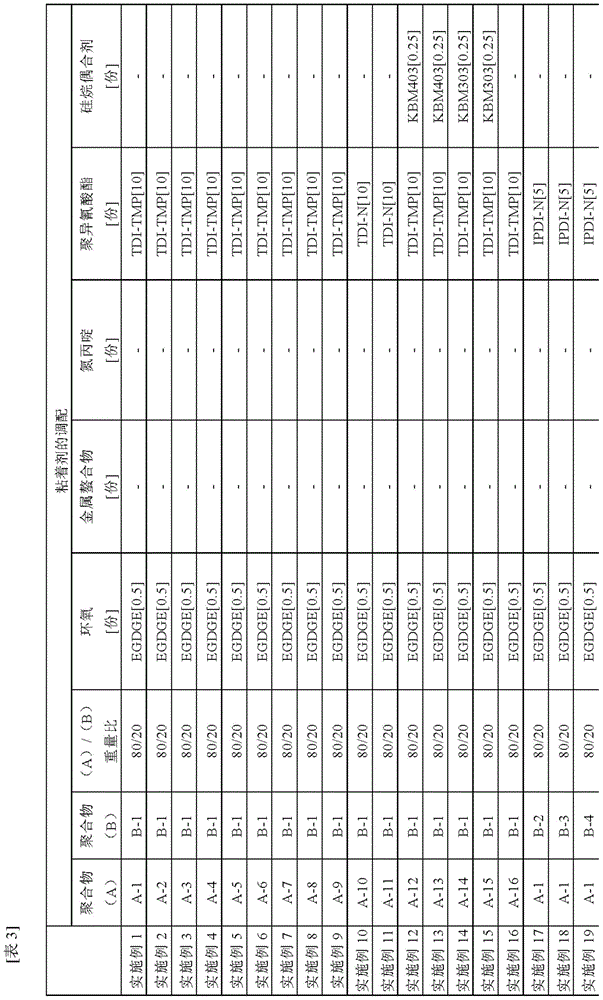

[0120] Examples of the present invention are shown below and described in more detail, but the present invention is not limited to these Examples. In the examples, "parts" means "parts by weight", and "%" means "% by weight".

Synthetic example 1

[0121]

[0122]In a reaction vessel equipped with a stirrer, a thermometer, a reflux cooling pipe, a dropping device, and a nitrogen introduction pipe (hereinafter referred to as "reaction vessel"), 99.5 parts of butyl acrylate, 0.5 parts of acrylic acid, 100 parts of ethyl acetate, 2, 0.025 parts of 2'-azobisisobutyronitrile (hereinafter referred to as AIBN), and the air in the reaction container was replaced with nitrogen gas. Then, it heated to 80 degreeC, stirring in nitrogen atmosphere, and started reaction. Then, the reaction solution was reacted at reflux temperature for 7 hours. After the reaction was completed, it was cooled, diluted with ethyl acetate, and the non-volatile content was 30%, the viscosity was 3000m (Mw), and the result was that the weight average molecular weight was 1,000,000. Let the obtained copolymer be a copolymer (A-1).

[0123]

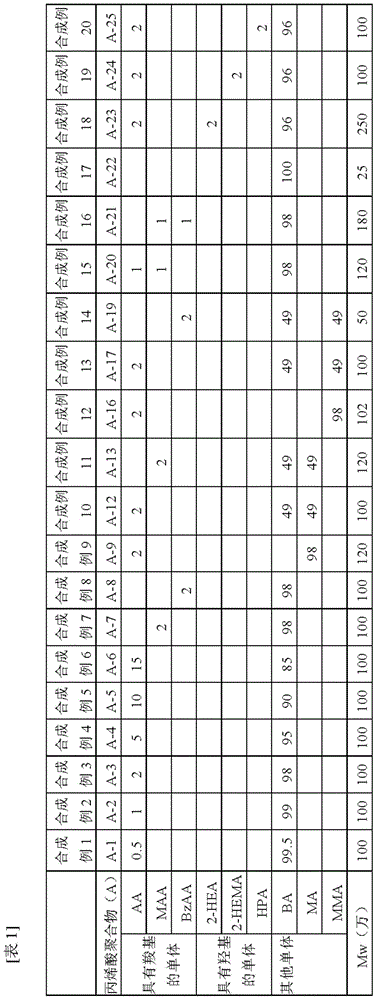

[0124] Various raw materials were injected|thrown-in according to the weight ratio of Table 1, and the acrylic ...

Synthetic example 21

[0125]

[0126] 99.8 parts of butyl acrylate, 0.2 part of 2-hydroxyethyl acrylate, 100 parts of ethyl acetate, and 0.025 parts of AIBN were charged into the reaction container, and the air in the reaction container was replaced with nitrogen. Then, it heated to 80 degreeC, stirring in nitrogen atmosphere, and started reaction. Then, the reaction solution was reacted at reflux temperature for 7 hours. After the reaction was completed, it was cooled and diluted with ethyl acetate to obtain a copolymer solution with a non-volatile content of 30% and a viscosity of 3000 mPa·s. Moreover, when the weight average molecular weight (Mw) of an acrylic copolymer was measured using GPC, the weight average molecular weight was 1 million. Let the obtained copolymer be a copolymer (B-1).

[0127]

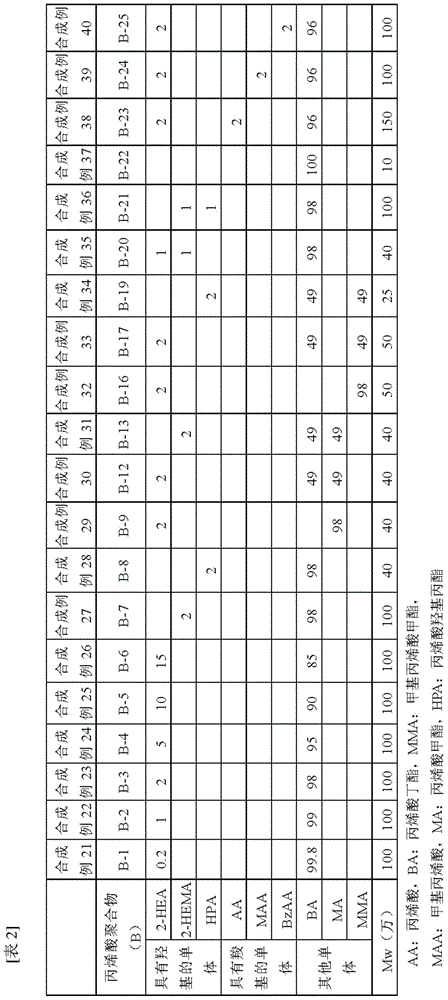

[0128] According to the weight ratio of Table 2, various raw materials were charged, and the acrylic copolymer (B) was synthesize|combined by the method similar to synthesis example 21. Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com