Ultrahigh strength steel stamping part rebound control method

A technology of ultra-high-strength steel and control methods, which is applied in the field of stamping and forming, can solve problems such as springback of ultra-high-strength steel plates, and achieve the effects of improving forming accuracy, preventing serial movement, and reducing cross-sectional openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

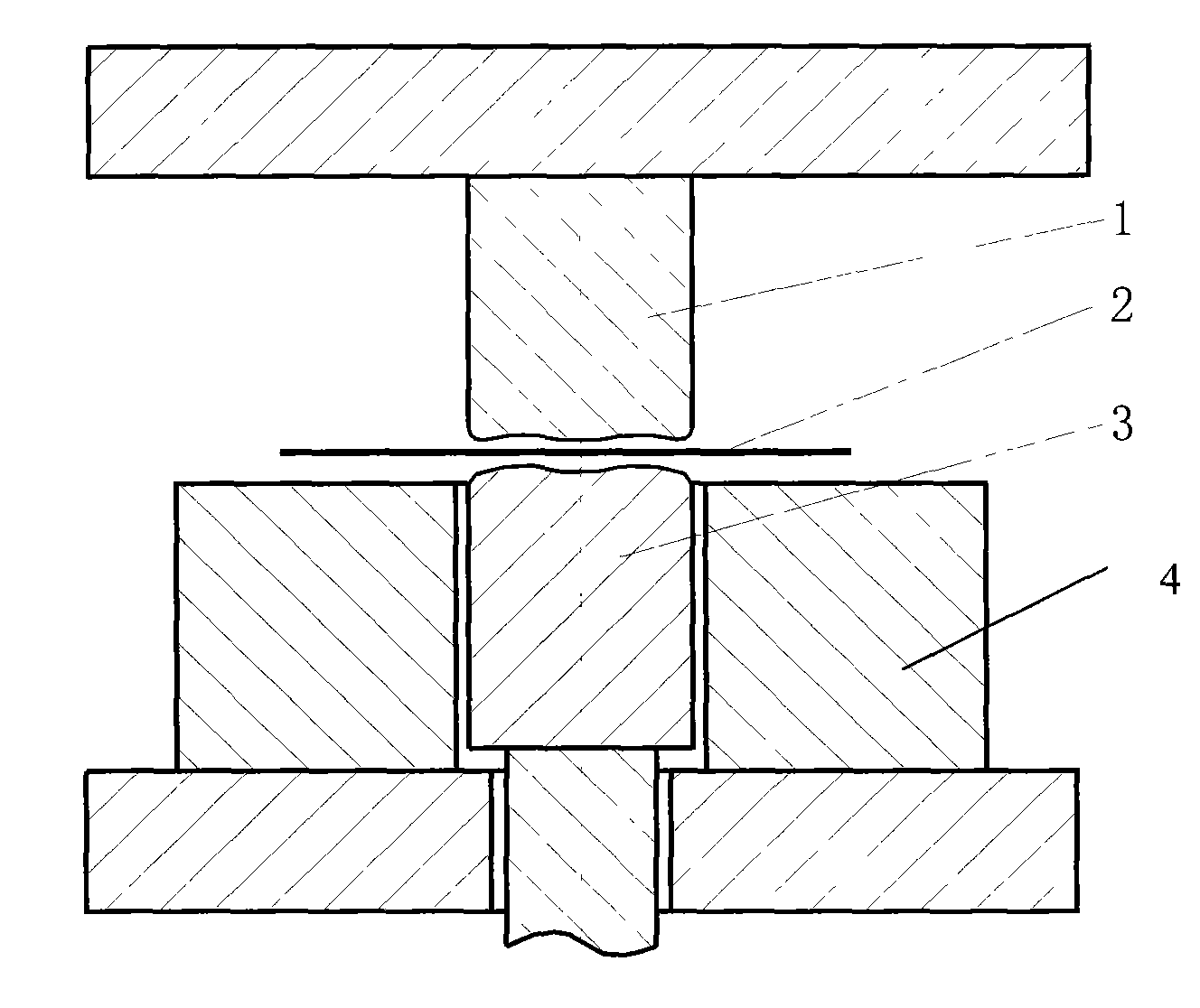

[0012] The method of the present invention will now be further described in conjunction with the accompanying drawings.

[0013] As shown in the accompanying drawings, the mold of the present invention includes main parts such as punch 1, die 4, and top plate 3. The position of the arc is corresponding and the direction is opposite. The arc on the surface of the punch is concave, and the arc on the surface of the top plate is convex. Deformation, after the stamping is completed, this part of the deformation recovers to compensate for the springback of the two side walls, so that the sheet can obtain higher forming accuracy. The more serious, the larger the arc; the springback direction of the side wall of the plate is outward, so the deformation direction of the arc part should be the opposite deformation, that is, the surface of the punch is concave, and the surface of the top plate is convex. The reason why the bottom surface of the punch and the upper surface of the top pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com