Casing leakage plugging small workover operation method

A casing and workover technology, which is used in earth-moving drilling, sealing/isolation, wellbore/well components, etc., can solve problems such as wellhead pollution, deterioration of wellhead environment, and non-compliance with environmental protection requirements, so as to reduce well workover costs. , the effect of saving costs, great economic value and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

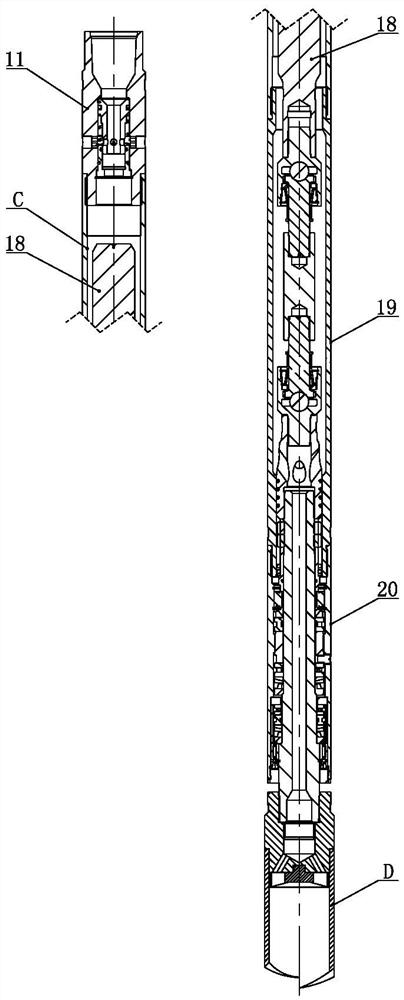

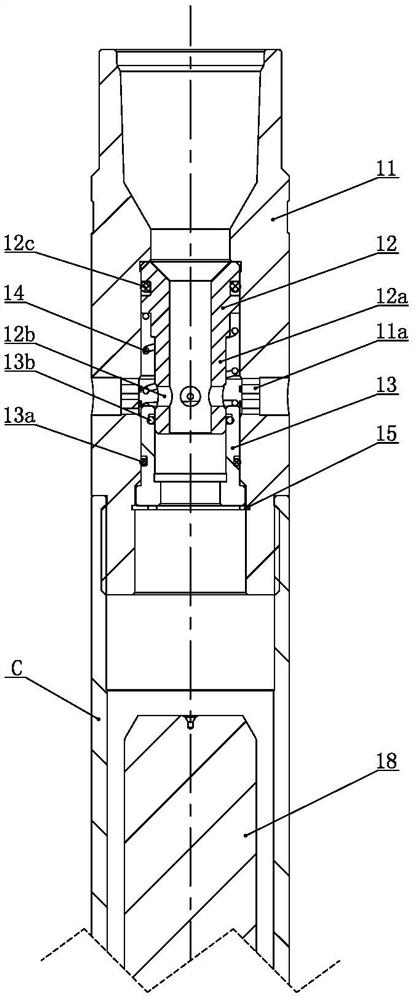

[0033] The casing leakage plugging and small workover operation method of the present invention comprises the following steps in turn: (1) determining the position of the casing leakage section; (2) placing a bridge plug at 50-100 m below the casing leakage section; (3) placing a bridge plug above the rubber plug Fill the protective layer of quartz sand more than 10 meters; (4) Inject cement slurry into the lower oil pipe to the top of the leaking section; (5) After the oil pipe string is pulled up to the bottom of the oil pipe string and the bottom of the oil pipe string is at a safe distance of 50-100m from the top of the cement slurry, the wellhead is closed and the cement slurry is squeezed out Enter the leakage layer, and ensure that the top of the cement slurry is still higher than the top of the seepage section; (6) Shut in the well under pressure, and the cement slurry should set for more than 36 hours; (7) Pull out the oil flow string, drill the ash string to drill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com