Saw blade guiding device and regulation method thereof

A technology of guiding device and adjustment method, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of limited control accuracy, unstable vibration control system, control type, and system instability, etc., so as to improve control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

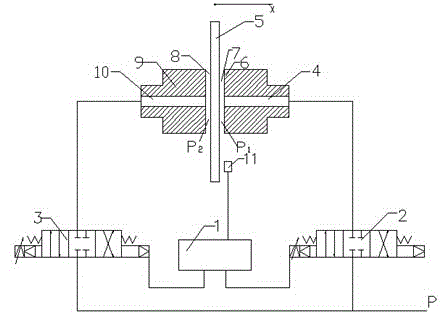

[0035] Such as figure 1 As shown, a saw blade guiding device includes a controller 1, the controller is connected with a displacement sensor 11, and the saw blade 5 is located in the effective sensing area of the displacement sensor 11; both ends of the controller are provided with a first pneumatic servo valve 2 and a second pneumatic servo valve. Two pneumatic servo valves 3, the first pneumatic servo valve 2 and the second pneumatic servo valve 3 are in communication with the air source P; both sides of the saw blade 5 are provided with a first guide disc 6 and a second guide disc 9, and the center of the first guide disc 6 A first through hole 4 is provided, a second through hole 10 is provided in the center of the second guide disc 9, a first gap 7 is formed between the first guide disc 6 and the saw blade 5, and a gap 7 is formed between the second guide disc 9 and the saw blade 5. A second gap 8 is formed; the air source passes through the first pneumatic servo valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com